D

GB

F

E

5

96156-05.2013-DGb

1|Safety

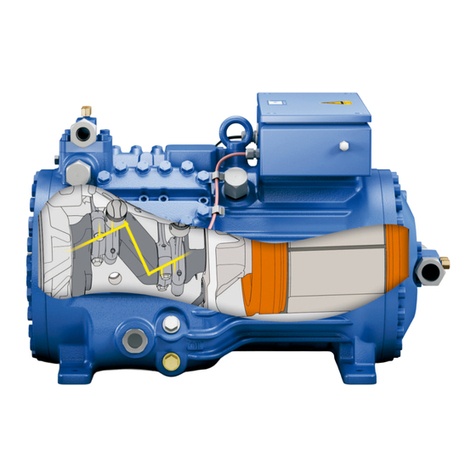

These assembly instructions describe the standard version of the compressors named in the title

manufactured by Bock. Bock refrigerating compressors are intended for installing in a machine

(within the EU according to the EU Directives 2006/42/EC Machinery Directive, 97/23/EC Pressure

EquipmentDirective).

Commissioning is only permissible if the compressors have been installed in accordance with these

assembly instructions and the entire system into which they are integrated has been inspected and

approved in accordance with legal regulations.

The compressors are intended for use with CO2in transcritical and/or subcritical systems in

compliance with the limits of application.

Onlytherefrigerantspeciedintheseinstructionsmaybeused.

Any other use of the compressor is prohibited!

1.4 Intended use

1.3 Safety instructions

WARNING Riskofaccident.

Refrigerating compressors are pressurised machines and

thereforerequireparticularcautionandcareinhandling.

Themaximumpermissibleoverpressuremustnotbeexceeded,

even for testing purposes.

Riskofburns!

-Dependingontheoperatingconditions,surfacetemperaturesof

over 60 °C on the pressure side or below 0 °C on the suction side

can be reached.

- Avoid the contact with refrigerant under any circumstances.

Thecontactwithrefrigerantcanleadtosevereburnsandskin

irritations.

Danger of suffocation.

NeverreleasesignicantvolumesofCO2or the entire contents of

the system into closed rooms!

•TranscriticalCO2applications are still in the development phase.

•Theyrequireacompletelynewkindofsystemandcontrol.

•TheyarenotageneralsolutionforthesubstitutionofF-gases.

•Therefore,weexpresslypointoutthatallinformationinthis

assembly instruction has been provided according to our current

levelofknowledgeandmaychangeduetofurtherdevelopment.

Legal claims based on the correctness of the information cannot

be made at any time and are hereby expressly excluded.

WARNING The compressor may not be used in potentially explosive

environments!