Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

How To Operate Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

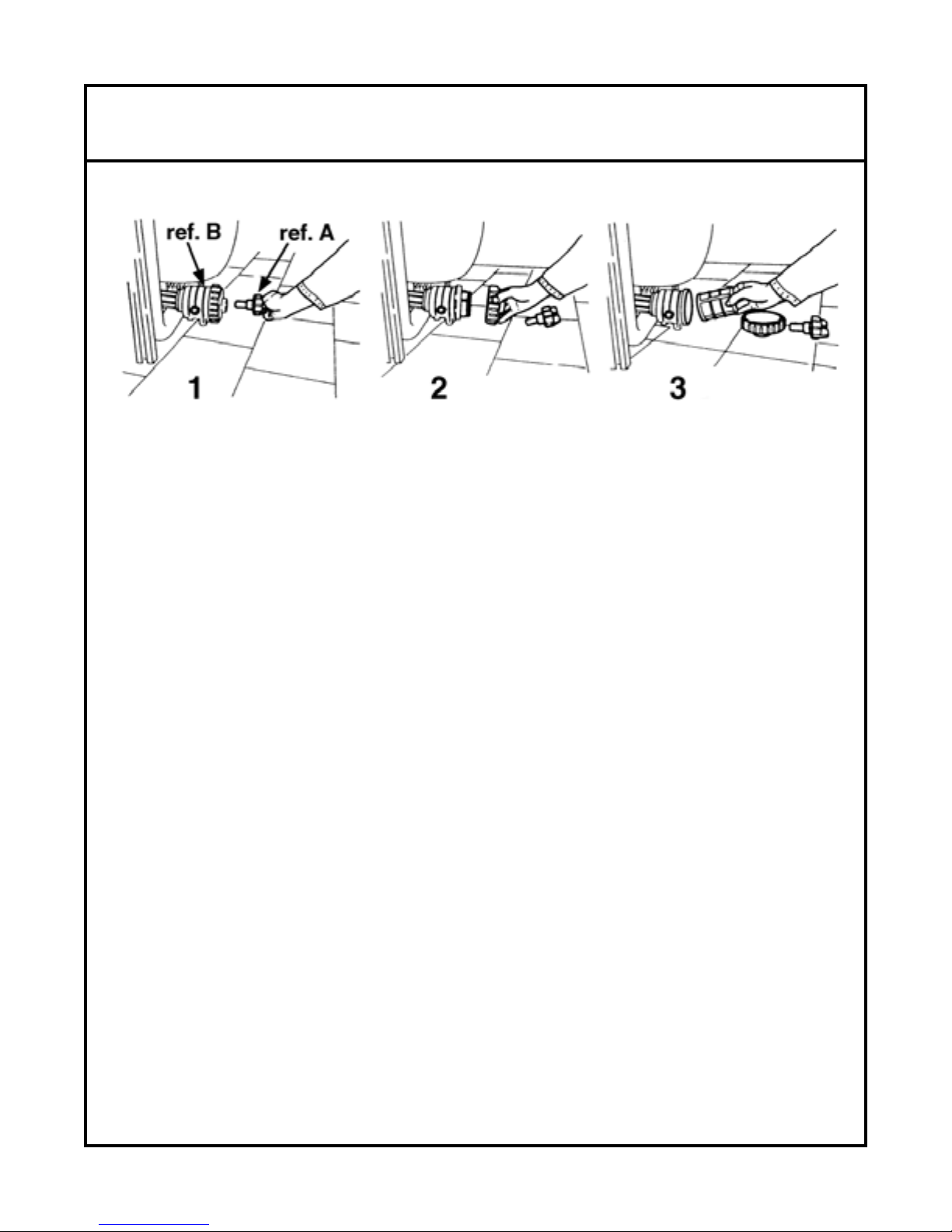

Suction Filter Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pump Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rate Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Tank Assembly 50 Gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Tank Assembly 100 & 150 Gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-15

Run of Fluids 50 Gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-18

Run of Fluids 100 & 150 Gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-21

Electric Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-23

Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-26

Optional Volute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27-29

Gearbox Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-31

Sprayer Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-34

Nozzle Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Tommy Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36-37

Pump Assembly for GDL200 & APL200 . . . . . . . . . . . . . . . . . . . . . . .38-40

GS40 Valve Assembly for GDL200 & APL200 . . . . . . . . . . . . . . . . . . .41-42

Pump Assembly for GDL400, 600, APL400 & 600 . . . . . . . . . . . . . . .43-45

GS40 Valve Assembly for GDL400, 600, APL400 & 600 . . . . . . . . . .46-47

Hose Reel Assembly 112-4-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48-49

Hose Reel Assembly 1125-4-325 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-51

Driveline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

TABLE OF CONTENTS

Date of Purchase:__________________________

Model Number:____________________________

Serial Number:____________________________