We welcome you as an owner of a set of Gearmore Quick Attach Bucket

Forks. Please read the following instructions and refer to them when

required:

These forks are intended to convert your loader into a forklift for limited use. Since your loader

was not specifically designed as a forklift, extra care must be taken when operating, such as the

following:

1. Know the capacity and limitations of the forks.

2. Know your machines characteristics and operating procedures.

3. Study and know the safety procedures in this manual and the manual

provided with your tractor.

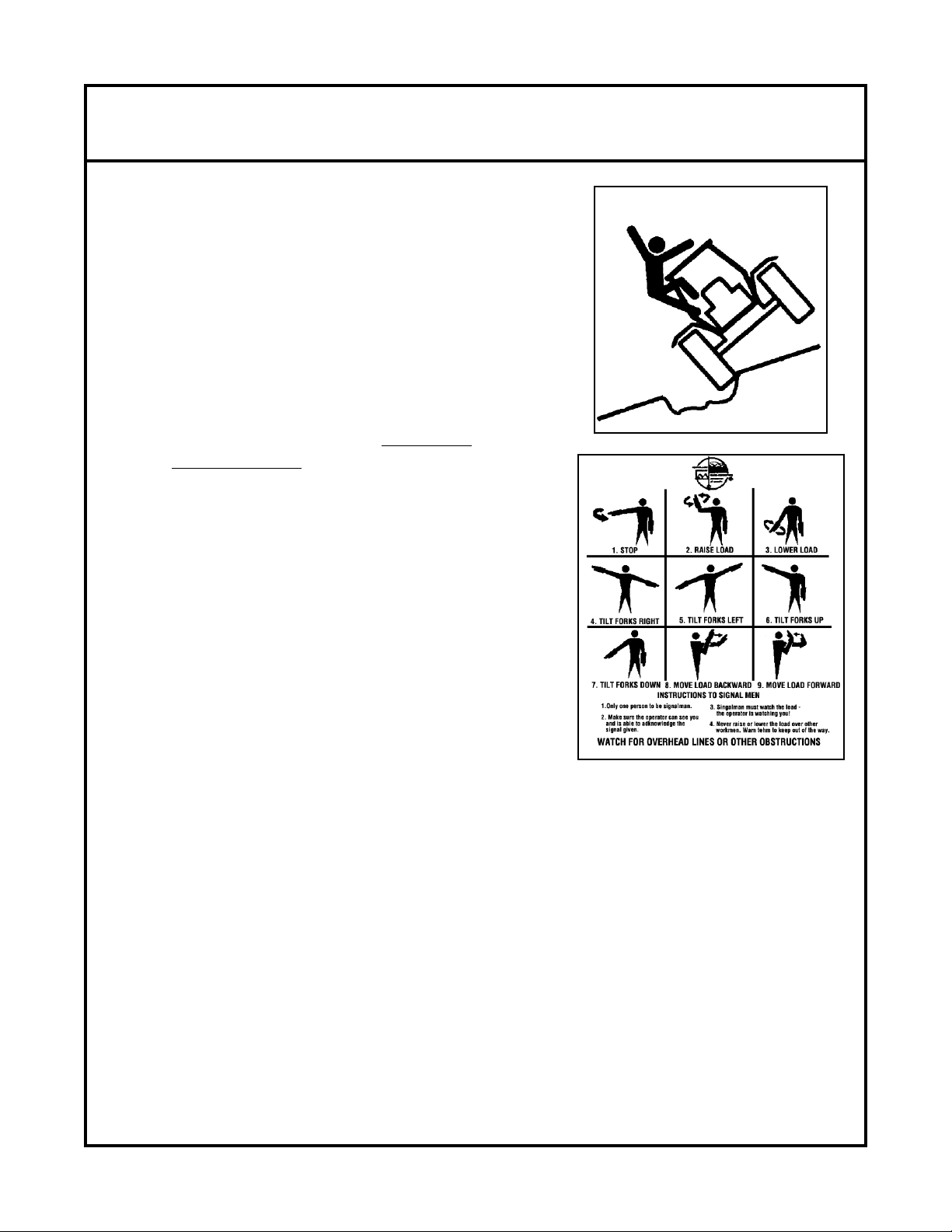

4. When in the field, refer to the safety decals on the forks (Ref. A). If at any time, over the

life of the forks, your safety decal becomes damaged, contact your dealer or Gearmore for

free replacement (909) 548-4848.

INTRODUCTION

Page 1

CAUTION

USE OF FORKS CAN BE EXTREMELY DANGEROUS! YOU

OR OTHERS CAN BE HURT BY:

TIPPING THE MACHINE LOSING THE LOAD

KNOW YOUR SAFETY RULES!

Before operating fork equipped loader, read your fork

owner's manual! Use extreme caution when operating!

ALWAYS KEEP LOAD CENTERED ON TINES AND MACHINE!

PROTECT YOURSELF!

Never roll back forks so that the load can fall on you or

others!

BEFORE DISMOUNTING MACHINE PLACE FORKS ON GROUND!

Never leave machine with a raised load! Always follow machine

manufacturers recommendations for dismounting and parking

machine.

USE OF FORKS WILL REDUCE MACHINE STABILITY!

Use extreme caution when lifting and transporting loads! Follow

machine manufacturers recommendations for use of counterweights

and other ballast!

KNOW YOUR MACHINE!

Never lift or transport more than your machine can handle!

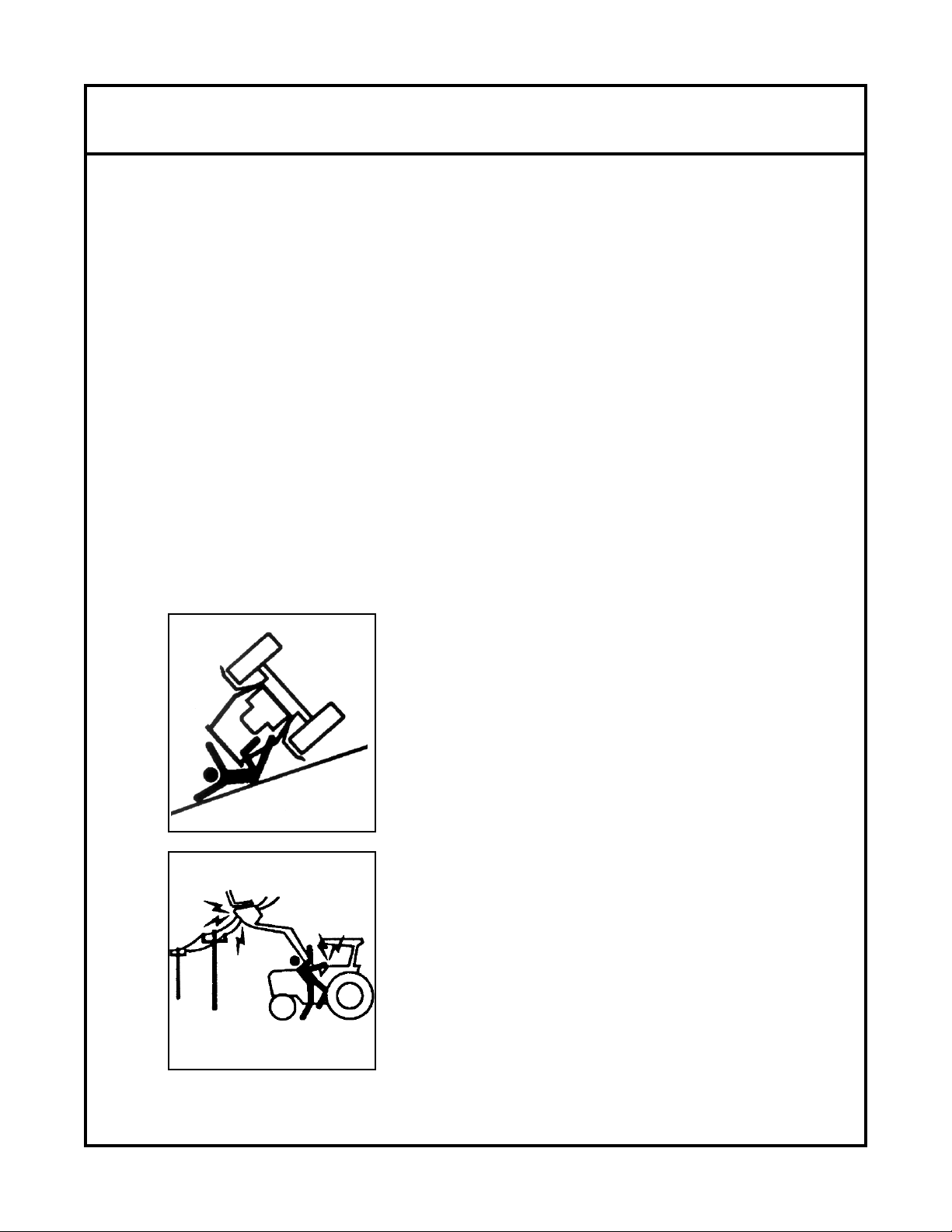

RAMPS, GRADES, AND BUMPY OR SOFT GROUND WILL GREATLY

REDUCE YOUR MACHINE'S STABILITY!

Lifting and transporting loads under these conditions is extremely

dangerous! Use Extreme Caution!

KEEP FORKS AS LOW AS POSSIBLE DURING OPERATION!

KNOW YOUR SAFETY RULES!

GEARMORE, INC.

13477 Benson Ave.

Chino, CA 91710

(909) 548-4848

Ref. A