CAUTION! Do not short the motor leads to each other or to ground; damage will result to the G251.

4-wire, 6-wire and 8-wire motors may be used. When 6-wire motors are used, they may be connected in half winding or full

winding. This is equivalent to an 8-wire motor connected in parallel or series. If a motor is connected in series or full winding, the

motor’s phase current rating is half of its parallel or unipolar rating. The choice depends on the high-speed performance required;

a parallel-connected motor will provide twice the power of a series-connected motor at the same power supply voltage.

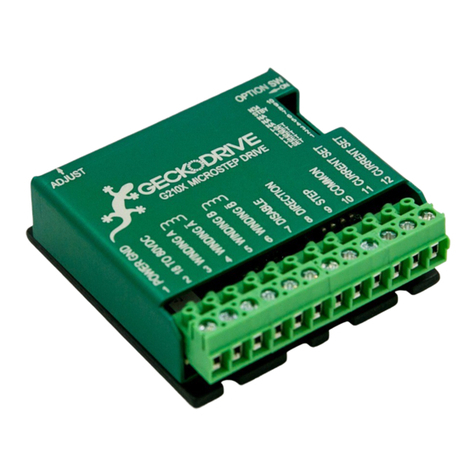

STEP AND DIRECTION INPUTS

TERMINAL 9 Direction

Connect the DIRECTION line to this terminal.

TERMINAL 10 Step

Connect the STEP line to this terminal.

These terminals can be driven with 3.3V or 5V logic. If 3.3V logic is used then the input current is -1mA for logic “0”and zero for

logic “1”. If 5V logic is used then the input current is -1mA for “0”logic and 0.67mA for logic “1”.

DISABLE PIN

TERMINAL 11 Disable

This terminal will force the winding currents to zero when shorted to ground (TERMINAL 12).

Shorting this input to ground (terminals 11 to 12) forces winding currents to zero and stops all output switching activity. The G251

will continue totalizing step and direction inputs if any are sent. The power supply current drops to less than 15mA. The motor will

return to its original position when the disable input is released if no step pulses have been sent and the motor has not been moved

more than 2 full steps.

COMMON PIN

TERMINAL 12 Common

Connect this terminal to the controller signal ground

This pin is the other end of your STEP and DIRECTION signal and must be connected to GND. Without a GND connection the

drive will not respond to control inputs.

HEATSINKING

The G251 needs heatsinking for current settings greater than 3 amps. The case temperature (measured on the bottom plate) should

not exceed 70 degrees C, and for best life should be kept to 50 degrees C or less. Use heatsink compound between the G251 and

the heatsink.

CAUTION! Current settings above 3 Amps without a heatsink will result in damage to the G251.

The drive must be heatsinked to a piece of aluminum, preferably with fins and a fan to increase heat dissipation and surface area.

Do not screw the drive directly to the door of your control cabinet, as this will typically not provide adequate heatsinking

properties.

ADJUSTING THE TRIMPOT

This trimpot adjusts the motor for the smoothest possible low-speed operation. Set the motor speed to about 1/4 revolution per

second, and then turn the trimpot until a distinct null is noted in the motor’s vibration. This will result in the most even microstep

placement for a given motor and power supply voltage.