14662 FRANKLIN AVE.

SUITE# E

TUSTIN, CALIFORNIA 92780

1-714-832-8874

GECKODRIVE INC.

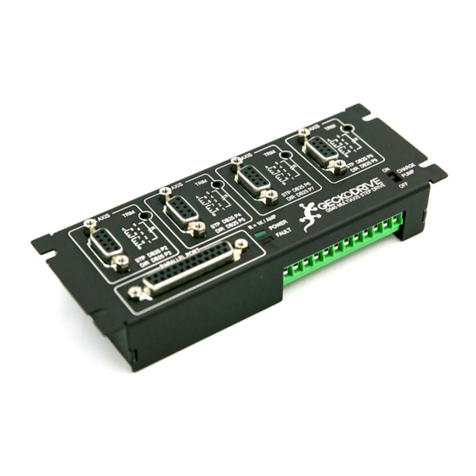

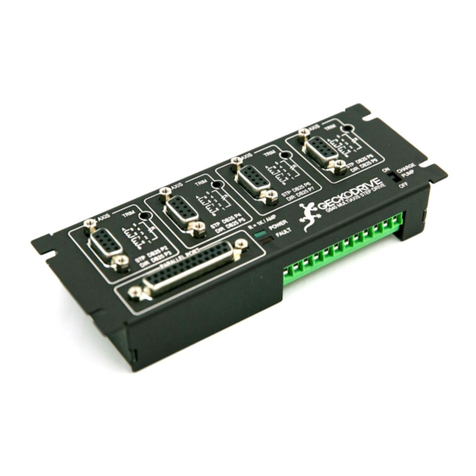

G540 4-AXIS DRIVE

USERS MANUAL REV-1 August 5, 2008

GENERAL: Thank you for choosing to purchase the G540 4-Axis Drive system. If you are dissatisfied with it for any

reason at all within two weeks of its purchase date, you may return it for a full refund provided it is cosmetically

unmarred and undamaged electrically in any way. Otherwise Geckodrive Inc. fully warranties it against workmanship

defects for 1 year after its purchase date.

The G540 is very easy to use. All it requires is:

1) MOTORS: One to four step motors are required. All NEMA-17, many NEMA-23 and a few NEMA-34 motors are

acceptable. The motors preferably should be square in cross-section, not round. The motors can be 4, 6 or 8-wire

motors. 5-wire motors cannot be used with the G540. Choose a motor that has a rated current of 3.5A or less.

Choose a motor that has a rated winding inductance of 2.5mH to 3mH if maximum power output (>100W mechanical)

is a requirement. Never use a power supply voltage greater than 32 times the square-root of the motor inductance

expressed in milli-Henries (mH).

2) MOTOR CABLES: The motors connect to the G540 via male DB9 connectors. The four motor wires connect to

pins 6 and 7 for one motor winding, pins 8 and 9 for the other motor winding. The current set resistor connects to pins

1 and 5. The motor cable should be a 4-conductor cable and it can be shielded or unshielded. If a shielded cable is

used, connect the shield to either pin 2, 3 or 4. Pins 2, 3 and 4 connect to ground inside the G540.

3) CURRENT SET RESISTORS: The current set resistor programs the axis drive current (0 to 3.5A) to match the

rated phase current of the motor being used with the axis. Each axis requires a current set resistor. The resistor can

be from 1/10 W to 1/2 W in size and 1% to 5% tolerance. The current set equals 1,000 Ohms per Amp of motor

current. Example: A 3.3A per phase motor requires a 3.3K resistor, a 1.5A per phase motor requires a 1.5K resistor.

4) POWER SUPPLY: Connect a DC power supply to the MAIN TERMINAL BLOCK, the positive supply wire to Pos

11 and the negative (ground return) wire to Pos 12. The power supply voltage must be between +18VDC and

+50VDC. The power supply voltage determines how fast your motors can go. Supply voltage has no effect on the

motor’s low-speed torque. The power supply can be regulated or unregulated. The power supply current will depend

on the number of motors used and the motors rated phase currents. The power supply current also depends on

motor speed and applied load. A rule of thumb estimate is add up all the motor phase currents and multiply the result

by 0.6 to get the required power supply current.

5) PARALLEL PORT CABLE: Use a parallel port cable to connect the G540 to the PC. The G540 end of the cable

must be a male DB25 connector.

The following items are optional, based on how the G540 is to be used:

6) +5VDC: The PC 5VDC must be supplied to Pos 1 on the MAIN TERMINAL BLOCK if the G540 inputs are going to

be used. 5VDC is available from any USB port, the mouse connector or the keyboard connector.

7) E-STOP SWITCH: Connect a single pole, single throw (SPST) switch to the DISABLE input Pos 6 on the MAIN

TERMINAL BLOCK. The other end of the switch goes to Pos 12 on the terminal block. Closing the switch disables

the G540 and opening the switch enables it. While disabled, the motors freewheel (zero torque) and the OUTPUT

terminals shut off.

8) INPUTS: The G540 has four general purpose inputs called INPUT 0, INPUT 1, INPUT 2 and INPUT 3 on the MAIN

TERMINAL BLOCK. They are at Pos 2, Pos 3, Pos 4 and Pos 5 respectively on the terminal block. These inputs may

be used as limit switches or for any other purpose. SPST switches can be used with these inputs; one end of the

switch goes to the input, the other end of the switch goes to ground (Pos 12).

9) OUTPUTS: The G540 has four general purpose outputs called OUTPUT 0, OUTPUT 1, OUTPUT 2 and OUTPUT

3 on the MAIN TERMINAL BLOCK. They are at Pos 7, Pos 8, Pos 9 and Pos 10 respectively on the terminal block.

These outputs may be used to drive relay coils or for any other purpose. The outputs are rated at 1A and 50VDC

maximum. Connect one end of the load to the output and connect the other end of the load to a positive DC voltage.

This voltage may be the G540 power supply or it may be a separate power supply having a different voltage.