280380A_MHW_IR-12/IR-24_11-2015_ENG

1.1 Profile

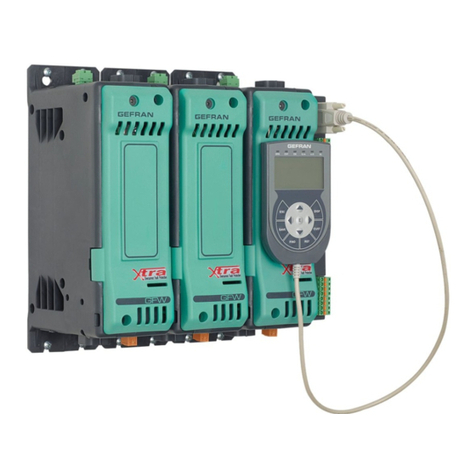

The compact, powerful, smart Power Controller IR-12/IR-24 is the

ideal solution for multichannel Infrared lamps heating systems.

In a unique, robust, “all in one” wall mounting cabinet are

available all the necessary components for the complete IR

lamps management for up to 60Kw electrical power.

The product is available in different models: IR-24 (with 24

outputs) , or IR-12 (with 12 outputs) and they are available

with communication RS485 MODBUS RTU or with Fieldbus

PROFINET. Each one of the 24 channels available can be

controlled independently by commands received on the

FieldBus or on the RS485 communication line, with Modbus

RTU protocol and baud rate selectable up to 57.600 bps.

The channels are able to provide 9Amps as maxixmum current

per channel on all the 24 channels contemporary.

The soft start phase, useful to grant a gradual heating of the

lamps and so a longer lifetime, is provided by phase angle

control.

When the lamp filament is warm, after the soft start phase, the burst

firing control takes place, with a typical cycle time of 2 seconds.

It can be configured also the Phase-angle (PA_mode) firing

steady-state control mode.

Using the zero crossing firing method is possible to avoid the

EMC emission and consequently evoiding to use expensive and

space consuming EMC filters.

IR-12/IR-24 is equipped with a local brain able to provide a

continuos monitoring of the power percentage provided by the

single channel in order to act a time-sharing distribution.

The result is a continuous balancing of the istantaneus absorption

on each phase of the power line, with big advantages in term of

current peaks reduction, increasing of the system power factor,

finally money saving for the machine/line users.

Another local control is performed locally by the IR-12/IR-24 in

order to compensate the line voltage variations, risulting in the

capability to grant a constant power to the lamps even when the

voltage power supply is not constant in the factory.

Complete exhaustive diagnostic functions are available for each

single channel as for the central unit.

The fault conditions of lamp out, fuse blown, scr in short circuit,

loss of phases, loss of 24Vdc power supply are all displayed by

common Leds and with a single diagnostic bit for each channel,

readable by Fileldbus or Serial Line.

The several trigger modes are software congurable and provide:

- BF: Burst-Firing, Zero crossing with optimized minimum cycle

time, for systems with low thermal inertia, medium-wave IR lamps

- HSC: Half Single Cycle Zero Crossing corresponds to Burst

Firing that manages single semi-cycles of conduction or stop

cycles, useful for short-wave IR lamps, reduces ickering and li-

mits generation of EMC noise on the power line

- PA: Phase-Angle, load control using phase angle SCR ring

modulation control

- Soft Start Ramp: With phase angle control to reduce current

peaks at ring .

IR-12/IR-24 runs complete diagnostics of current, voltage, power,

and temperature levels:

Current Diagnostics:

- Total load interrupt alarm

- Alarm for SCR in short circuit

Voltage Diagnostics:

- Alarm for absence of phase

Fuse diagnostics:

- Automatic detection of blown fuse (for every channel)

Temperature Diagnostics:

- Alarm for over temperature of power module

Power control with Soft start ramp limits load, optimizes the con-

sumptions and increases the load operating duration.

NOTE: In PA_mode the diagnostic Alarms Load-Open and

Fuse_open are detected for SCR power ring higher than 40%

NOTE: In PA_mode the diagnostic Alarm SSR-SHORT is de-

tected when SCR power ring is P=0% or when his channel is

disabled

The IR-12/IR-24 can be connected serially by means of an

RS485 with Modbus RTU protocol or by Fieldbus PROFINET in

order to control the power outputs, the load state, and the device

from an HMI or PLC.

The section contains general information and

warnings to be read before installing, configuring and

using the controller.

1.2 General DescriPtion

IR-12/IR-24 is multizone advanced solid state power unit,

extremely compact, equipped with different functions; it offers

an exclusive combination of performance, reliability, and

flexibility.In particular, this new line of Gefran controllers is the

ideal solution for sectors demanding high performance and

continuity

of service, such as:

• IR welding

• Thermoforming

• Blowing

• Hot runners for injection presses

• Texturizing of fibers

• Heat treatment furnaces

• Woodworking machines

• Glass tempering furnaces.

IR-12/IR-24 is used for the power control of single-phase (phase

neutral) loads, including resistive loads with high and low

temperature coefficient, short wave IR lamps.

Attention: the description of programming and

configuration parameters are contained in

the “Programming and configuration” manual,

downloadable from the website www.gefran.com

1 • PRELIMINARY INSTUCTIONS