80224_MHW_650 L - 1250 L_07-2018_ENG - 1

CONTENTS..........................................................................1

Introduction.........................................................................3

Device data ......................................................................................3

Warnings and safety.........................................................................3

Symbols used in this manual ...........................................................4

Glossary ...........................................................................................4

Disclaimer.........................................................................................5

Copyright..........................................................................................5

1. General description.................................................. 6

1.1. Profile .....................................................................................6

1.2. Differences between models..................................................7

1.3. Indicator 650 L .......................................................................8

1.3.1. Display and keys 650 L...........................................................8

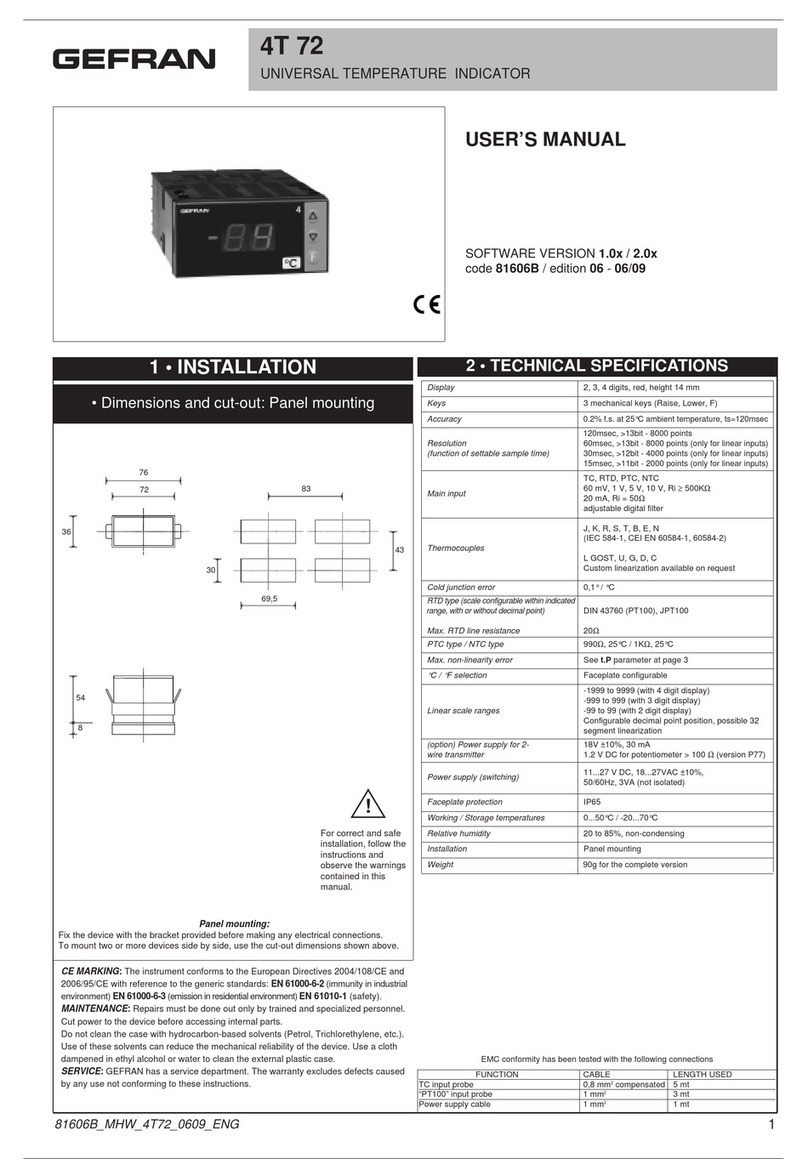

1.3.2. Cutout and mounting dimensions..........................................9

1.4. Indicator 1250 L ...................................................................10

1.4.1. Display and keys 1250 L.......................................................10

1.4.2. Cutout and mounting Dimensions .......................................11

2. Installation............................................................... 12

2.1. Mounting the indicator .........................................................12

2.1.1. General considerations.........................................................12

2.1.2. Mounting dimensions ...........................................................12

2.1.3. Protection against infiltration of dust .......................................

and water ........................................................................12

2.1.4. Vibrations...............................................................................13

2.1.5. Minimum space for ventilation .............................................13

2.1.6. Positioning.............................................................................13

2.1.7. Fastening to the panel ..........................................................13

2.2. Connections .........................................................................14

2.2.1. General considerations.........................................................14

2.2.2. Electromagnetic compatibility (EMC)...................................14

2.2.3. Cables ...................................................................................14

2.2.4. Power supply ........................................................................14

2.2.5. Connecting inputs and outputs............................................15

2.3. 650 L connection diagrams..................................................16

2.3.1. General diagram....................................................................16

2.3.2. Power supply ........................................................................17

2.3.3. Inputs.....................................................................................17

2.3.4. Outputs..................................................................................17

2.3.5. Options..................................................................................18

2.4. 1250 L connection diagrams................................................19

2.4.1. General diagram....................................................................19

2.4.2. Power supply ........................................................................20

2.4.3. Inputs.....................................................................................20

2.4.4. Outputs..................................................................................20

2.4.5. Digital inputs..........................................................................21

2.4.6. Serial line ...............................................................................21

2.4.7. Analog output........................................................................21

2.5. RS485 serial connection diagram ........................................22

3. Commissioning.......................................................23

3.1. Information on displays and use of keys..............................23

3.1.1. Menu navigation....................................................................23

3.1.2. Displays.................................................................................23

3.1.2.1. Display characters ...................................................23

3.2. Power-on sequence .............................................................24

3.1.2.2. Scrolling messages..................................................24

3.3. First power-on ......................................................................25

3.3.1. Fast configuration .................................................................25

3.4. Setting up quick configuration .............................................29

3.4.1. Setting up the Alarm ............................................................29

CONTENTS

CONTENTS

4. Configuration ..........................................................30

4.1. Programming/Configuration Menu.......................................30

4.1.1. First: know what you’re doing ..............................................30

4.1.2. Passwords.............................................................................30

4.1.3. Password in the User Menu .................................................30

4.2. Main menu ...........................................................................31

4.3. Legend for submenus and parameters................................32

4.3.1. Submenu...............................................................................32

4.3.2. Parameters............................................................................32

4.4. INFO Submenu - information display...................................33

4.4.1. SW.VER - Software Version..................................................34

4.4.2. CODE - Serial address of the indicator................................34

4.4.3. ERROR - Primary input error................................................34

4.4.4. SAP.C - SAP code.................................................................34

4.4.5. SEr.n - Serial address of the indicator..................................34

4.4.6. xxxxx - Model of indicator....................................................35

4.4.7. INDIC - Type of indicator ......................................................35

4.4.8. OUT.A1 - Analog output 1 available .....................................35

4.4.9. x.IN.DG - Digital input available............................................35

4.4.10. RS485 - RS485 serial port available ....................................35

4.4.11. Out1 - Type of output ...........................................................36

4.4.12. Out2 - Type of output ..........................................................36

4.4.13. Out3 - Type of output ..........................................................36

4.4.14. OUT1.S - Number of cycles output 1 .................................36

4.4.15. OUT2.S - Number of cycles output 2 .................................36

4.4.16. OUT3.S - Number of cycles output 3 .................................37

4.4.17. T.DAYS - Total working days ................................................37

4.4.18. P.DAYS - Partial working days..............................................37

4.4.19. T.INT - Internal temperature of indicator ..............................37

4.4.20. T.MIN - Minimum internal temperature of the indicator.......37

4.4.21. T.MAX - Maximum internal temperature of the indicator ....38

4.5. I.MAIN Submenu - Configuration of main input...................39

4.5.1. tyPE - Selecting sensor type ................................................40

4.5.2. SBR.E - Enabling Sensor Break Alarm (SBR) ......................41

4.5.3. Lin - Linearization type..........................................................42

4.5.4. Unit - Displayed engineering units .......................................42

4.5.5. FILT - Digital filter ..................................................................42

4.5.6. FILT.D - Digital filter on PV display........................................43

4.5.7. DEC.P - Number of decimals displayed ..............................43

4.5.8. LO.SCL - Lower limit of scale...............................................43

4.5.9. HI.SCL - Upper limit of scale................................................44

4.5.10. OF.SCL - Scale offset correction..........................................44

4.5.11. LO.AL - Lower limit for alarms..............................................44

4.5.12. HI.AL - Upper limit for alarms...............................................44

4.6. ALARM Submenu - Configuration of alarms........................45

4.6.1. ALARM - Selecting the alarm to be configured...................46

4.6.2. d.i.x - Selecting direct or inverse alarm................................46

4.6.3. A.r.x - Selecting absolute or deviation alarm .......................46

4.6.4. n.S.x - Selecting hysteresis type..........................................46

4.6.5. PWON.E - Disabling the alarm at power-on ........................47

4.6.6. LATCH - Set alarm latching ..................................................47

4.6.7. HYSTE - Hysteresis ..............................................................47

4.6.8. DELAY - Alarm trip delay ......................................................48

4.6.9. MSG.AL - Alarm message....................................................48

4.6.10. MSG.AN - Alarm reset message..........................................48

4.6.11. BLK.AL - Flashing of PV display...........................................49

4.6.12. BLK.AN - PV display alarm flashing with alarm reset..........49

4.7. I.DIGT Submenu – Configuring digital inputs.......................50

4.7.1. I.DIG.N - Selecting the digital input......................................51

4.7.2. S.in.x - Defining the input state ............................................51

4.7.3. F.in.x - Selecting the assigned function................................51

4.7.4. MSG.IN - Selecting the digital input message.....................51

4.8. OUTPU Submenu – Configuring outputs............................52

4.8.1. OUT.N - Selecting the output ...............................................53

4.8.2. S.ou.x - Defining the output state ........................................53

4.8.3. F.ou.x - Selecting the function assigned to relay, logic or

Triac output ...........................................................................53