SPI SPI-P170 User manual

Table of contents

Other SPI Measuring Instrument manuals

SPI

SPI 10-702-9 User manual

SPI

SPI 20-186-3 User manual

SPI

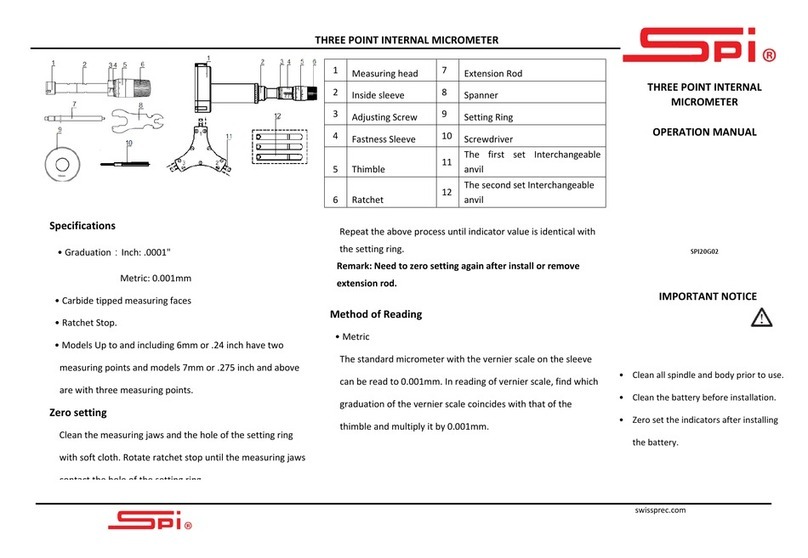

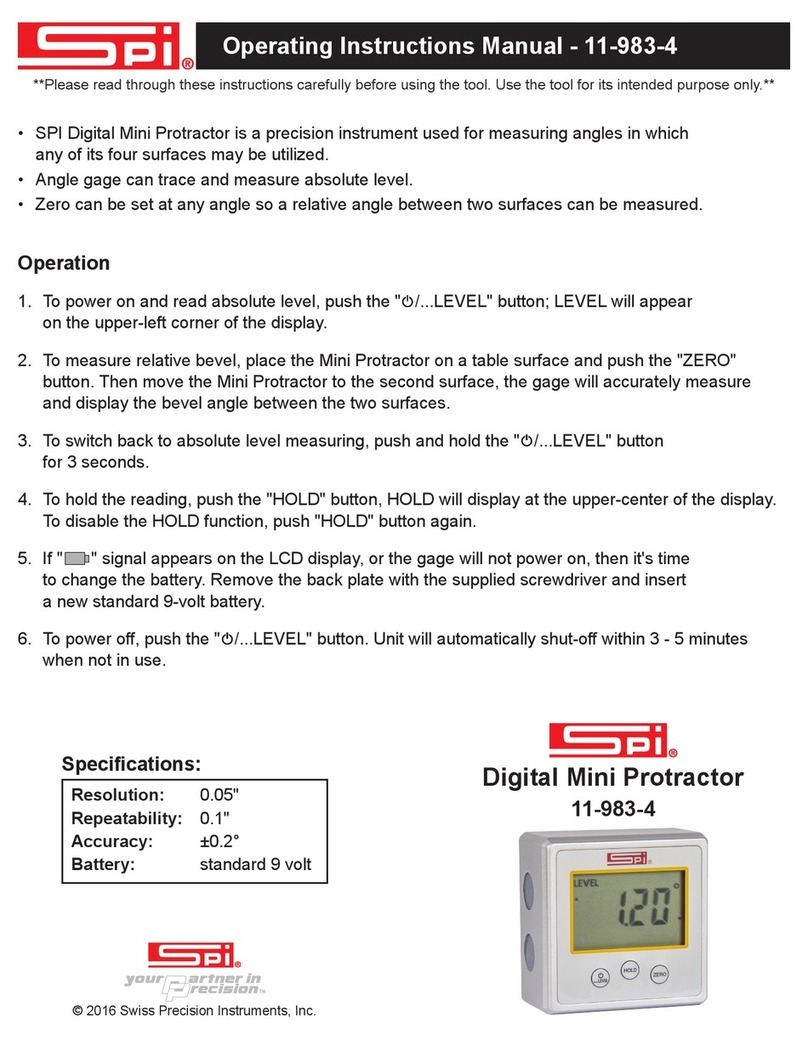

SPI 11-983-4 Instruction Manual

SPI

SPI 94200 Instruction Manual

SPI

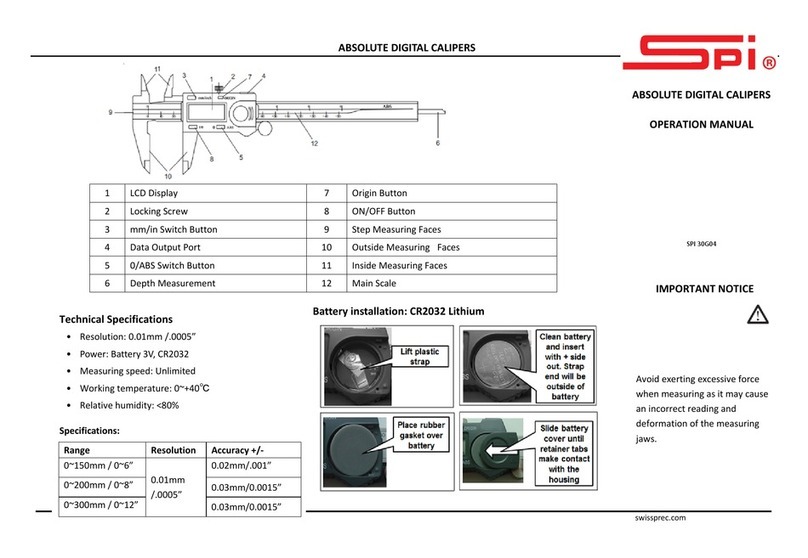

SPI ABSOLUTE DIGITAL CALIPER User manual

SPI

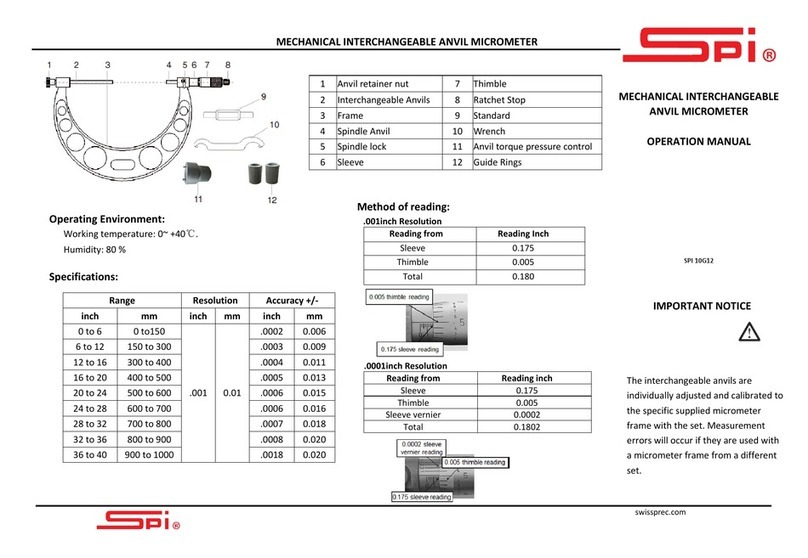

SPI 10G12 User manual

SPI

SPI 18-010-9 User manual

SPI

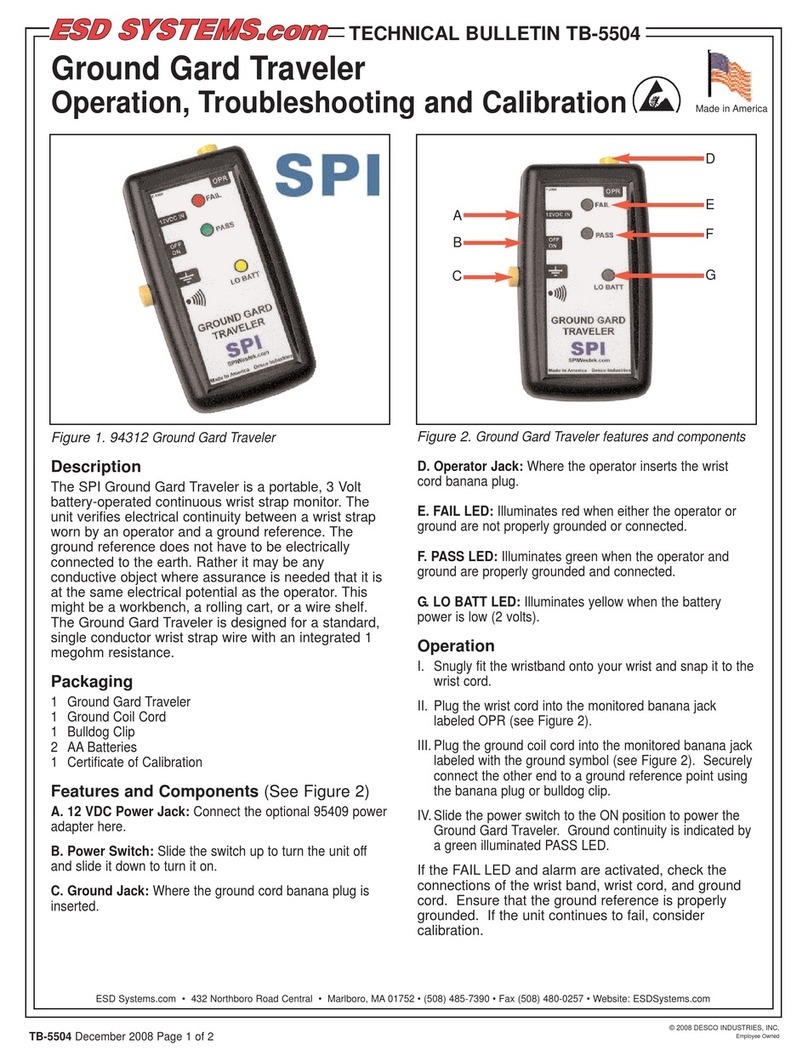

SPI Ground Gard Traveler Operating instructions

SPI

SPI C170 CHLORINE User manual

SPI

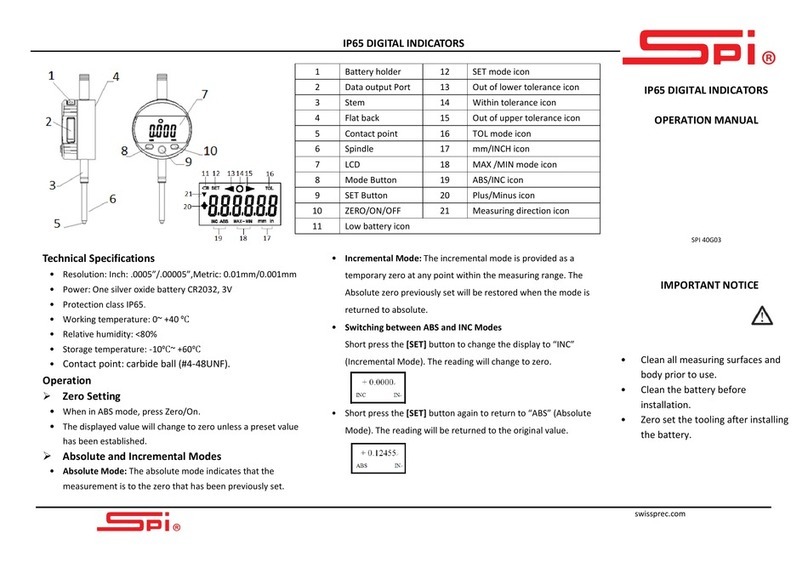

SPI 40G03 User manual

Popular Measuring Instrument manuals by other brands

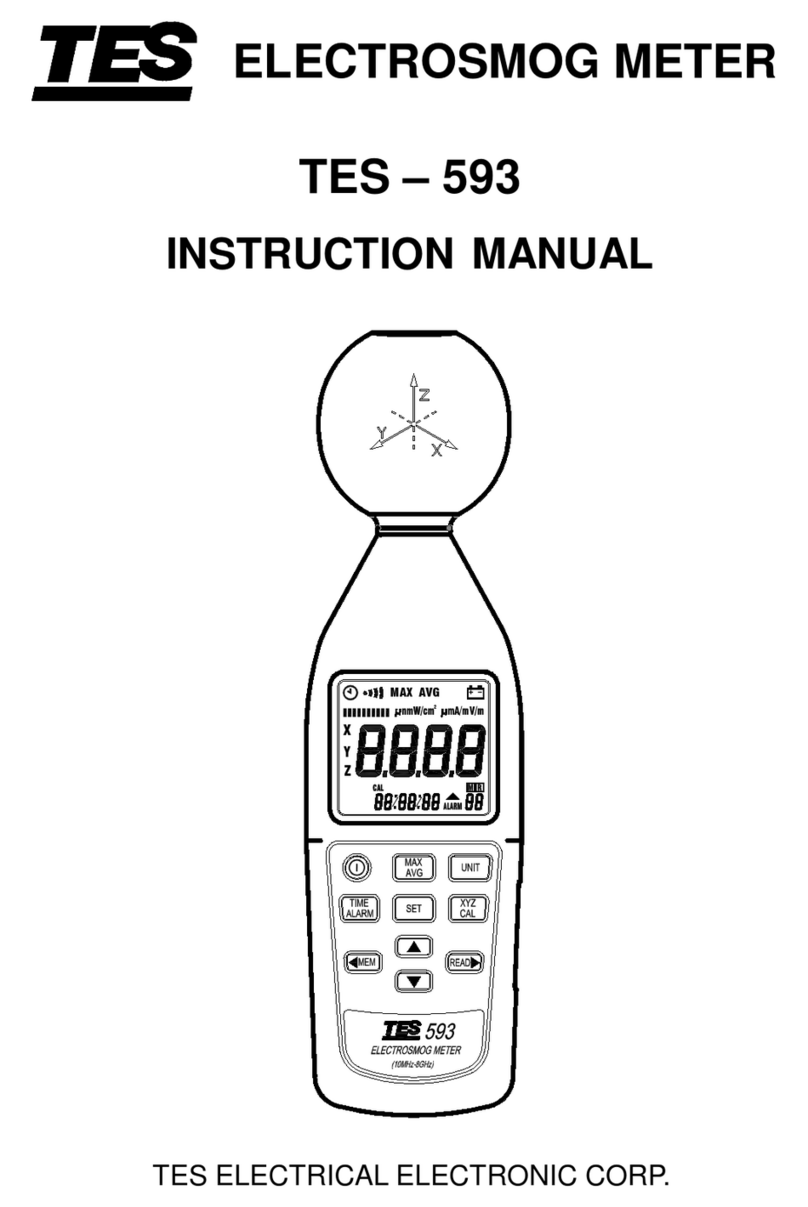

TES

TES 593 instruction manual

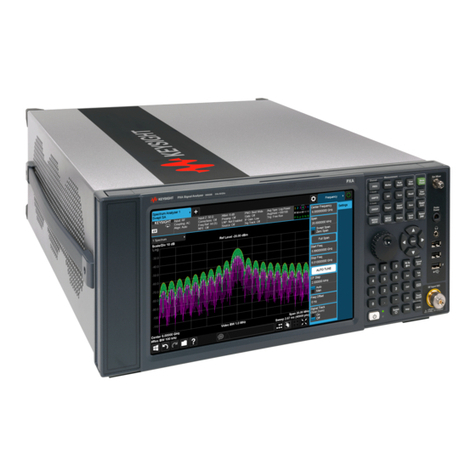

Keysight Technologies

Keysight Technologies N9030B Service guide

ElektroPhysik

ElektroPhysik MiniTest 725 Technical manual and operating instructions

Ametek

Ametek 3050 Series user manual

peret

peret FLUO instruction manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Sensa Core

Sensa Core Lacto Spark user manual

ETCR

ETCR 6800 user manual

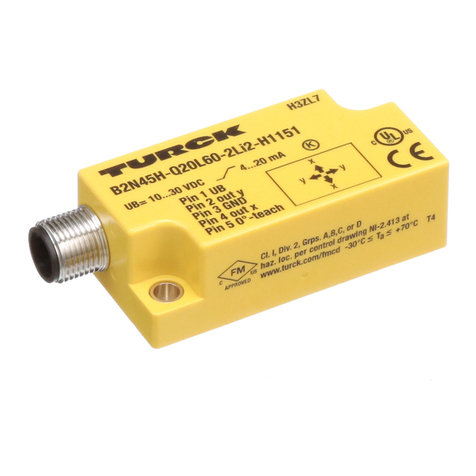

turck

turck B2N45H-Q20L60-2Li2-H1151/3GD quick start guide

Dwyer Instruments

Dwyer Instruments RP2 Specifications-installation and operating instructions

Tenmars

Tenmars TM-801 user manual