Operator Interface

All the operator interface devices are concentrated

on the controller faceplate, suitably protected by a mem-

brane in Lexan that guarantees IP65 level protection.

• 4buttonstobeusedformanualregulation/

configuration/selection

• 2greenfour-digitdisplays

(Process Variable and Set point Variable)

• 4redLEDsforstatusindicationofsamenumberof

relay/logic outputs

• 3LEDswithprogramfunctiontoindicatecontroller

operating mode.

Electrical Interface

All connection terminals (power supply, inputs, outputs,

options) are grouped together on the back of the

controller.

For technical specifications and performance details

refer to Section 5 “Technical Specifications”.

Preliminary Warnings

The following preliminary warnings should

be read before installing and using the series

1200/1300 controller . This will allow the control-

ler to be put into service more quickly and will

avoid certain problems which may mistakenly

be interpreted as malfunctions or limitations of

the controller.

• Immediatelyafterunpackingthecontroller,makea

note of the order code and the other identification

data given on the label affixed to the outside of the

container and copy them to the table below.

These details must always be kept close at hand and

referred to the personnel involved in the event of

help from Gefran Customer Service Assistance.

• Checkalsothatthecontrolleriscompleteandhas

not been damaged at all during transit, and that the

package contains not only the controller and these

Instructions for Use, but also the two brackets for

fixing to the panel and the dust protection seal - see:

Installation with Panel Fixing in Section 2.

Any inconsistencies, omissions or evident signs of

damage should be reported immediately to your

Gefran sales agent.

• Checkthattheordercodecorrespondswiththe

configuration requested for the application the

controller is needed for, referring to Section 7:

“Technical - Commercial Information”.

• No.andTypeofInputs/Outputsavailable

• Presenceofthenecessaryoptionsand

accessories

• Mainsvoltagesupply

Example: 1200 – RT – RR – 00 – 0 – 1

Model 1200 controller

Output 1 - Relay; Output 2 - Triac (1A)

Output 3 - Relay; Output 4 - Relay

No Digital Input

No Digital Communication

Mains Voltage 100...240Vac/dc

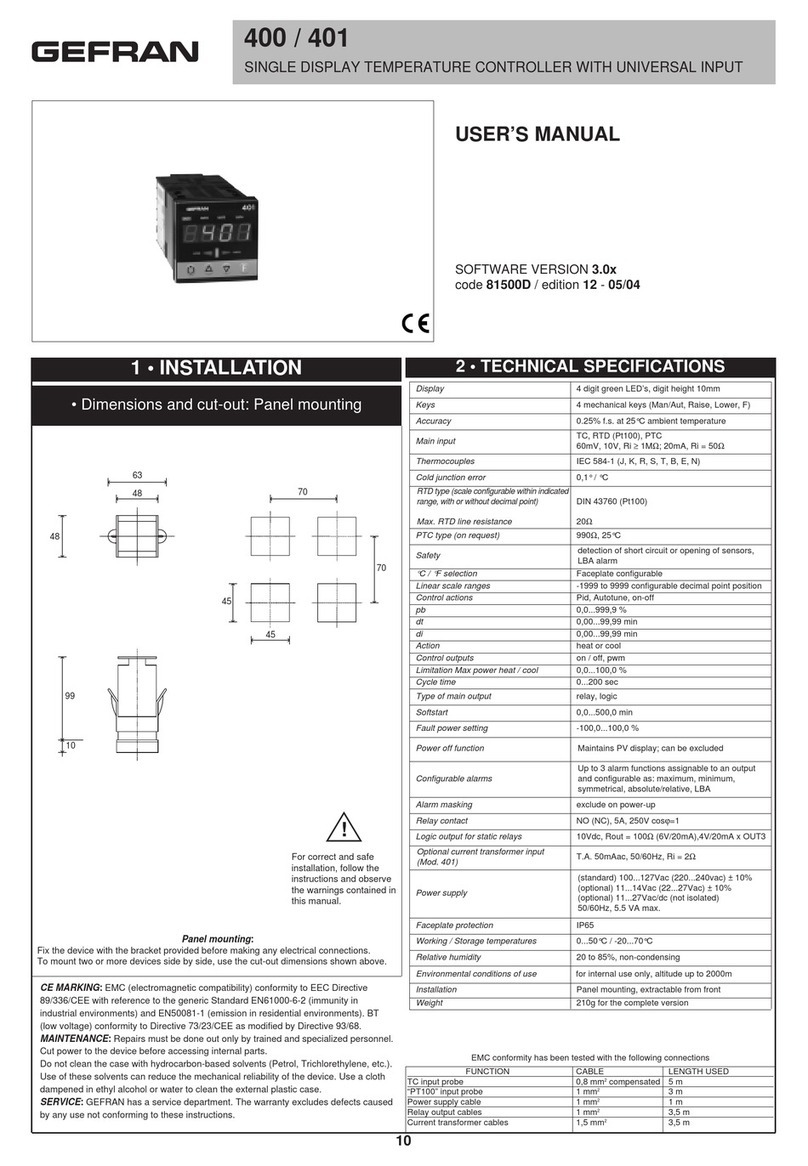

• Beforeinstallingtheseries1200/1300controlleron

the control panel of the machine or host system,

refer to the paragraph “Dimensions and Cut-out” in

Section 2 “Installation and Connection”.

• WhereconfigurationbyPCisprovidedfor,make

sure the interface RS232 cable is available and the

CD- ROM containing the WINSTRUM software.

For the order code refer to Section 7 “Technical -

Commercial Information”.

Users and/or system integrators who wish

to know more about the concepts of serial com-

munication between standard PC and/or

Gefran Industrial PC and Gefran Programmable

Instruments (including the series 1200/1300

controller), can access the various technical

reference Documents in Adobe Acrobat format

available in the Download section of the Gefran

Web Site www.gefran.com including:

•SerialCommunication

•MODBusProtocol

In the same Download section of the Gefran

Web Site www.gefran.com the 1200/1300

Temperature Controller reference manual is

available in Adobe Acrobat format, containing a

detailed description of all the adjustable

parameters and procedures for the Controller.

In the event of presumed instrument malfunction,

before contacting Gefran Technical Service

Assistance, refer to the Troubleshooting Guide

given in Section 6 “Maintenance”, and if

necessary refer to the F.A.Q. Section (Frequently

Asked Questions) on the Gefran Web Site

www.gefran.com

SN: ......................... (Serial no.)

CODE: ......................... (Finished product code)

TYPE: ......................... (Order Code)

SUPPLY: ......................... (Type of electrical power supply)

VERS: ......................... (Software version)

3

81801G_MHW_1200-1300_07-2011_ENG