5

4 Safety Notes

Besides this Operating Manual, and the requisite statutory safety regulations applicable in the

country and place of use, operators must also abide by the recognized codes of practice for

safe and workmanlike operation.

4.1 Principles; Correct Use

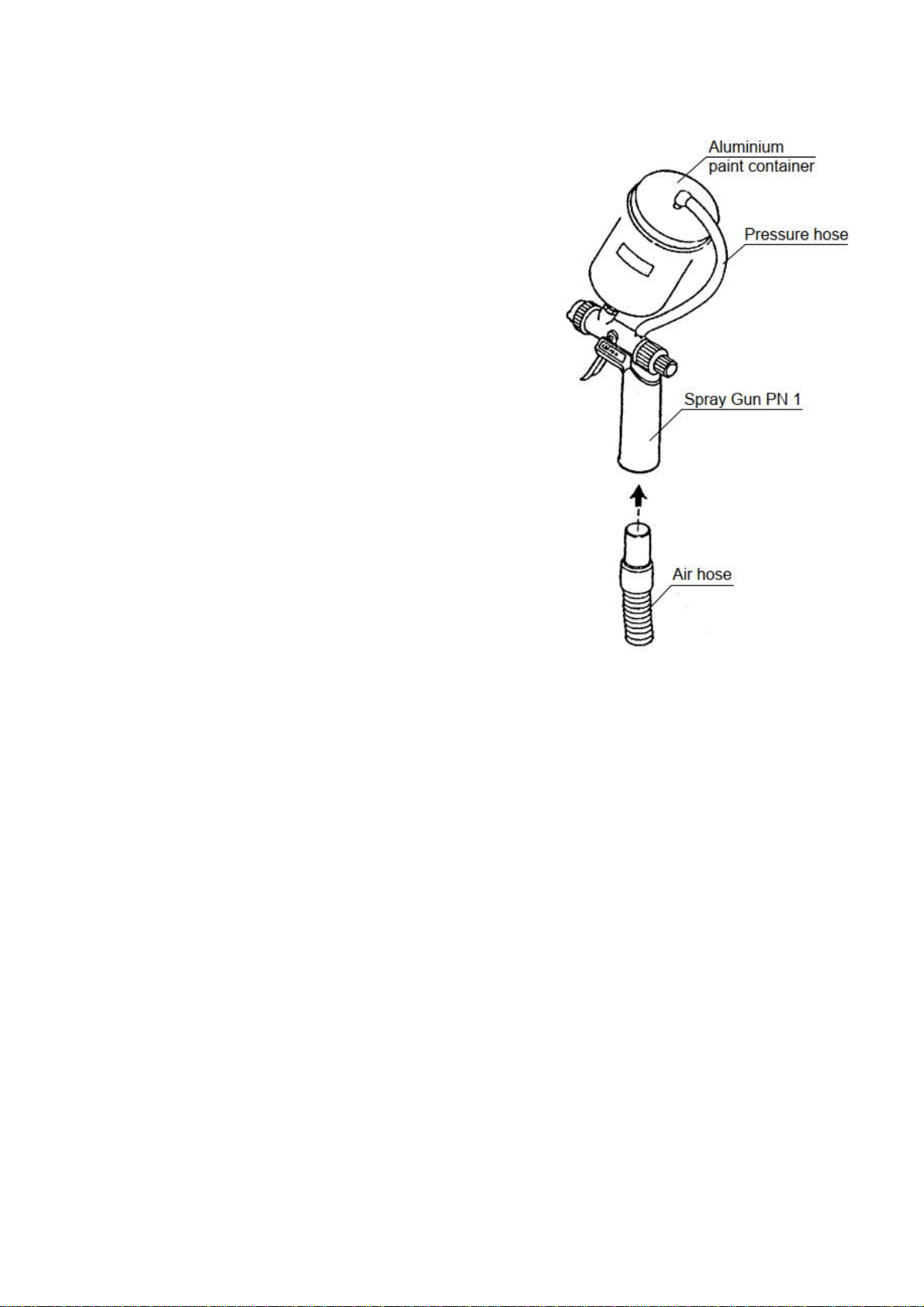

●The ABAC Spray Gun PN 1 / PN 1A is designed according to the latest technical findings

and complies with recognized safety regulations. However, if used improperly, there is a risk

of death or injury to the user or other persons, or of damage to the machine or other

property.

●The ABAC Spray Gun PN 1 / PN 1A should only be used for its intended purpose and when

it is in a perfect working order. The user must be safety conscious, fully aware of the risk,

and follow the operating instructions. Faults that could impair the operating safety of the

spray gun must be immediately remedied by an authorized person.

●The ABAC Spray Gun PN 1 / PN 1A must only be operated with low-pressure blowers (from

0,2 to 0,45 bar)! It is preferable to operate the spray gun in assembly with the original ABAC

low pressure paint-spraying units.

As a part of original ABAC units, the ABAC Spray Gun PN 1 / PN 1A should work only in

combination with ABAC SG 2000,ABAC SG 2500 and ABAC SG 3001 blowers. It is

prohibited to use this spray gun together with blower units, where operating air is also

applied for motor cooling (for example, with blower ABAC SG 90). In case of their co-use,

when air supply will be stopped for spraying (by trigger release), motor overheating and unit

breakdown may occur due to air backflow and accumulation.

Do not connect the spray gun to high-pressure blowers (from above 0,45 bar).

The equipment should never be used for any other purpose. The manufacturer or supplier is

not responsible and will not be liable for damage or injury resulting from improper use, which

shall be entirely at the user’s risk.

●Warranty obligations are valid only if the user observes the instructions and

recommendations described in this operating manual. Unauthorized changes and repair, use

for maintenance of spare parts other than original parts supplied with the product and

approved by the manufacturer or included in the spare parts list, as well operation of the

equipment under conditions other than those permitted in this manual, will void the

manufacturer’s guarantee for the ABAC Spray Gun PN 1 / PN 1A.