This instruction manual is intended solely for qualified professionals. All installations, electrical connections and

adjustments must follow the installation instructions.

Please read these instructions carefully and watch video instructions before installing this unit. Incorrect

installation may result in severe personal injury and/or damage to property.

Packaging materials (plastic and polystyrene, etc) should be discarded or recycled in accordance with waste

disposal regulations and should be kept out of reach of children.

Do not install this unit in any environment with potentials and risks of chemical explosions.

Make sure the existing structure is up to standard. GEM is not responsible for any damage resulting from

incorrect use of this unit.

The safety devices (e.g. photocell and emergency stop) must follow the technical safety regulations and

current safety standards, including the limit of forces and speeds.The safety devices must protect any areas

where the risk exists of being crushed, cut or gragged, or where there are any other risks generated by the

motorized door/gate. Apply hazard area notices required by applicable regulations.

Each installation must clearly show the identification details of the motorized door/gate.

Make sure the voltage specified is correct for the device.

Allow at least 10 seconds of rest time between every new cycle to ensure adequate residual current will

return to the power system.

When necessary, connect the motorized door/gate to a reliable earth system with applicable safety

regulations. Before carrying out installation, maintenance and repair, turn off the power supply before opening

the lid to access the electrical parts. To handle electronic parts, wear earthed antistatic conductive gloves.

1

Automatic Door Operator

Manual

1. General Safety Precautions

2. Declaration by Manufacturer

Gianni Industries, Inc.

Address: No. 13, Zhongxing Road, Tucheng District, New Taipei City 236, Taiwan (R.O.C.)

Website: www.gianni.com.tw

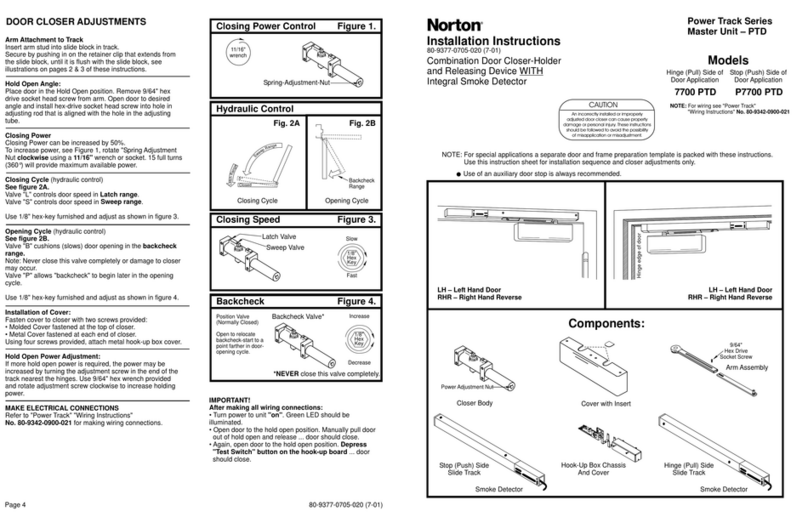

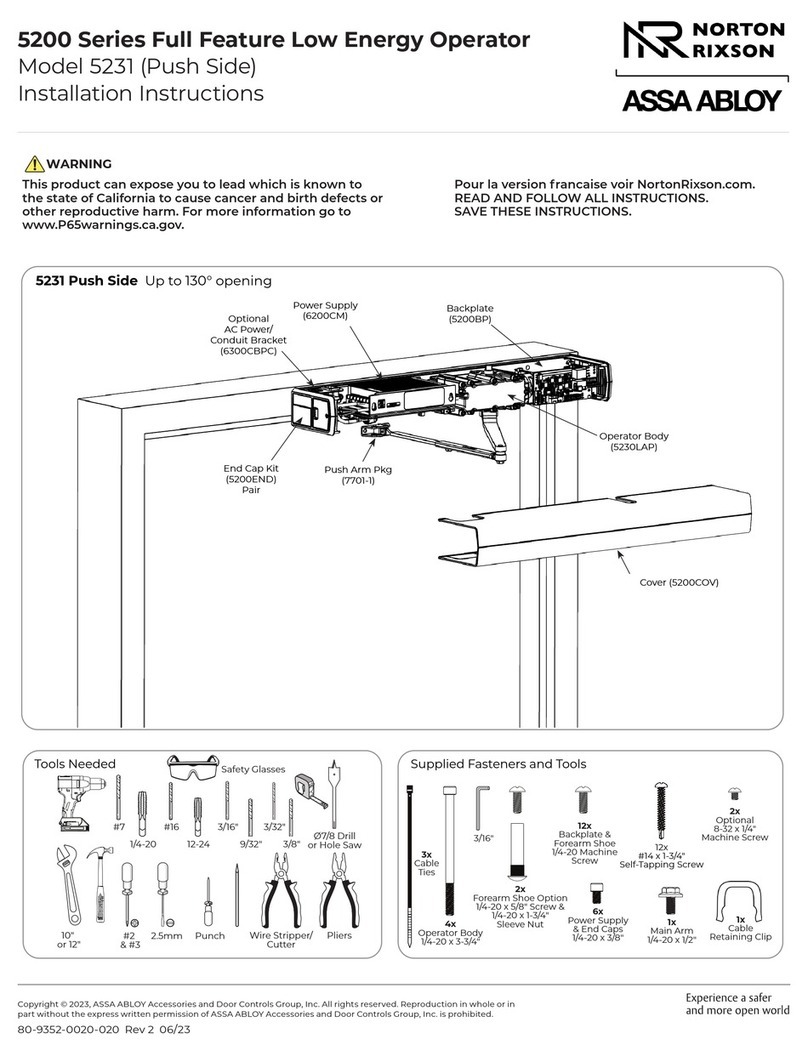

Herewith declares the following on AD500 Automatic Door Operator for swing doors:

AD500 is one way direction only and used on single doors

AD500 Automatic Door Operator cannot be installed with other mechanical devices (e.g. door closers) except

electric door locks.

UL listed and in conformity with other CE directives: Electromagnetic Compatibility Directive (EN61000) and Low

Voltage Directive (EN 60950-1)

Warranty: 3 years (Factory test: 1 million cycles)

Product should be operated within the recommended door weight range. A reduction in performance is expected

when operating outside of the recommended range.

The performance of the door operator may be affected by different independent variables such as friction, preload

(wind pressure), and other ambient factors. These factors may change the performance of the door operator and

its working life and parts. Furthermore, the surroundings must be considered to ensure the operator’s durability

and smooth operation.