Preface Installation Troubleshooting SpecicationsSettings

6

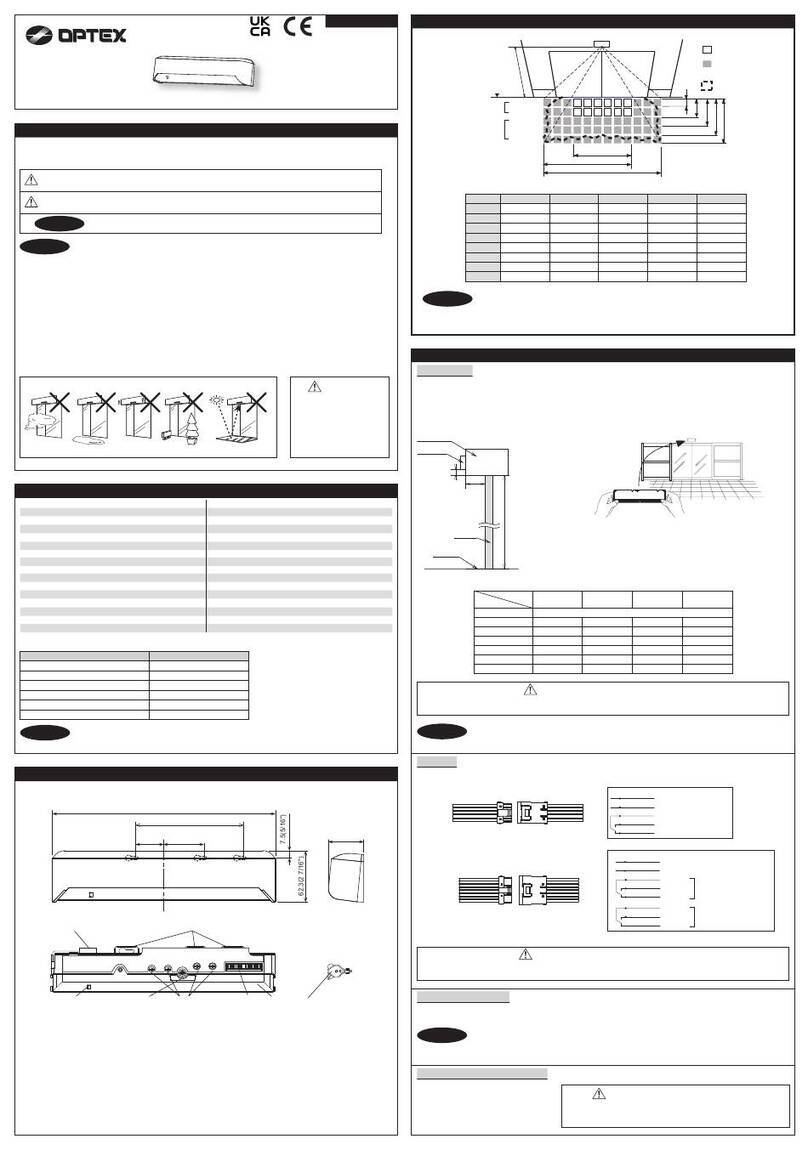

■Step 1) Installing OC-907C T and

connecting the loop harness

1Using the hook-and-loop fastener included as

standard, attach OC-907C T in the header.

2Connect the larger loop harness connector to the

OC-907C T sensor connector.

For double doors, connect another

sensor connector as well.

NOTE

With regard to the sensor connector, for single swing door

the OA-607 T can be connected to either the right/left

sensor connector. For double swing doors, the OA-607 T

installed on right/left doors can be connected to either

the right/left sensor connector (note that right/left must be

aligned for the door controller connector).

Loop harness 7'3" (2200 mm)

To OA-607 T

To OC-907C T

Smaller

connector

Larger

3Pass the loop harness through the transom and jamb.

To do so, drill a 3/8" (10 mm) hole in the transom.

* Later (see “Step 3-3”), a hole will be drilled in the jamb

for the loop harness to emerge.

■Step 2) Installing OA-607 T

1Decide in advance which side of the door (swing side

or approach side) to install the door loop on.

2Positioning the door template

Position the template edge at the door edge.

Mounting templates

For OA-607 T (R)

If through holes are required,

the height of both front/back

templates should be roughly

adjusted.

The door front/back through hole position should match on

both sides of the door.

Door front/back through hole since the holes here are

penetrated on both sides, the height of the both templates

should be roughly adjusted.

3Apply the door template to the door panel.

The template top should be between 6'7" (2.0 m) and 8'2"

(2.5 m) from the ground.

When the template is accurately positioned, align the 3/8"

(10 mm) through hole so that it matches on both sides of

the door.

4Drill 1/8"(3.2 mm) left and right mounting holes for

OA-607 T on each side of the door leaf (in accordance

with the mounting template).

5If through holes are required, drill a 3/8"(10 mm) cable

door through hole.

The approach side template hole must be perfectly aligned

with the swing side template hole.

6(Only on the door loop mounting door side)

Drill 1/8"(3.2 mm) holes at the door loop cover right

and left (in accordance with the door template) (one

side of the door leaf only).