Assa Abloy RIXSON W91DCP User manual

Other Assa Abloy Door Opening System manuals

Assa Abloy

Assa Abloy Yale 6000 Series User manual

Assa Abloy

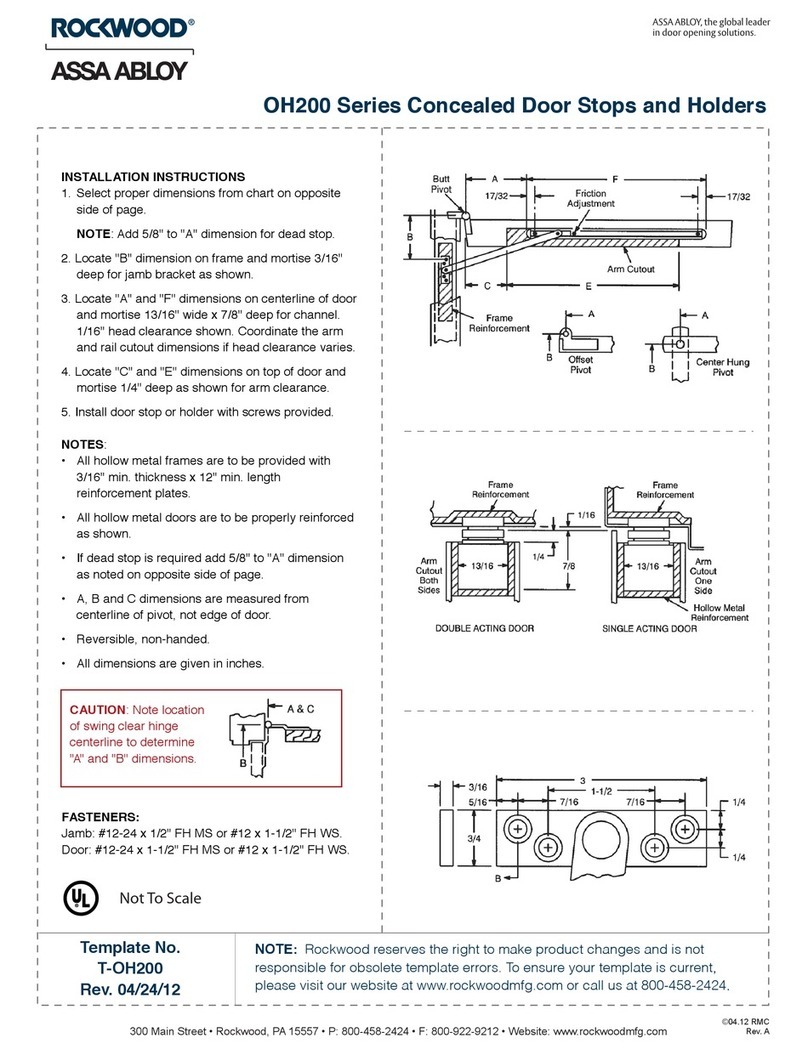

Assa Abloy Rockwood OH200 Series User manual

Assa Abloy

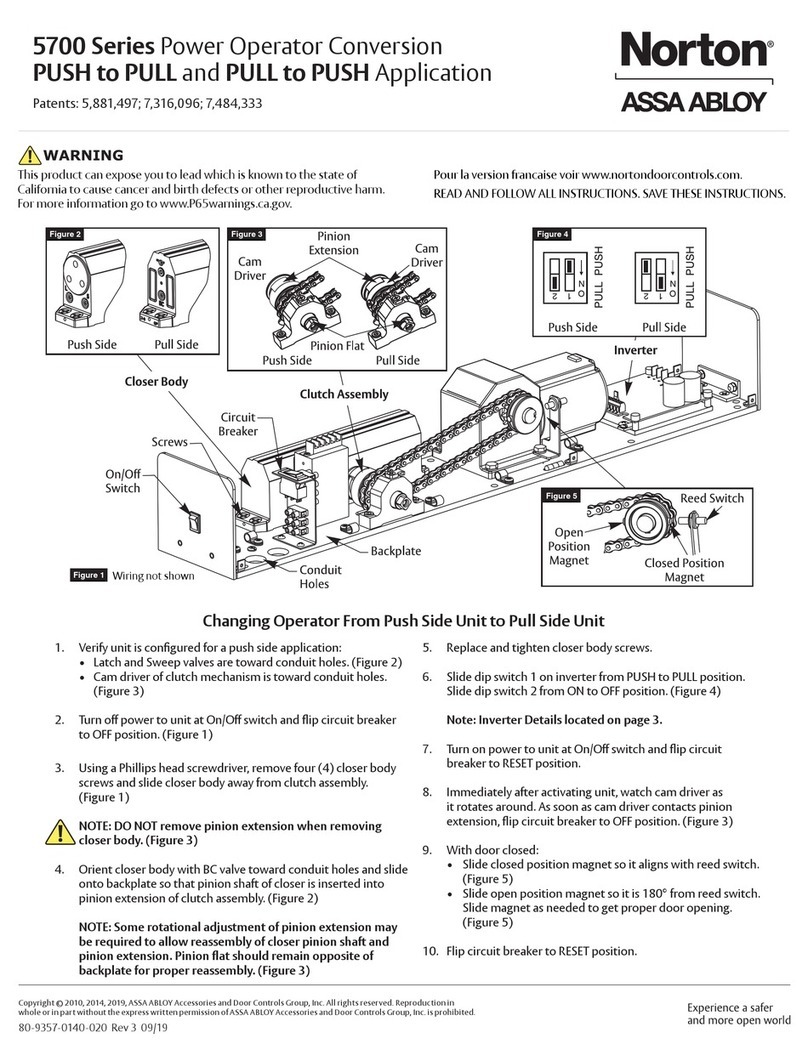

Assa Abloy Norton 5700 Series User manual

Assa Abloy

Assa Abloy CMD User manual

Assa Abloy

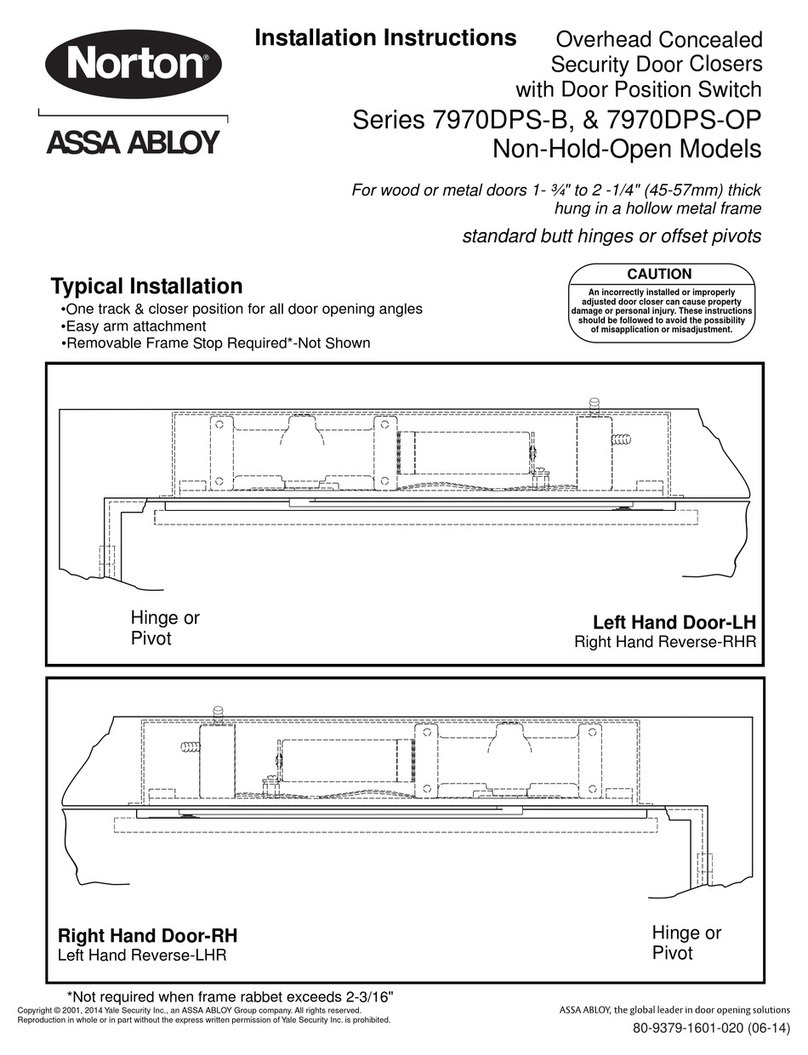

Assa Abloy Norton 7970DPS-B Series User manual

Assa Abloy

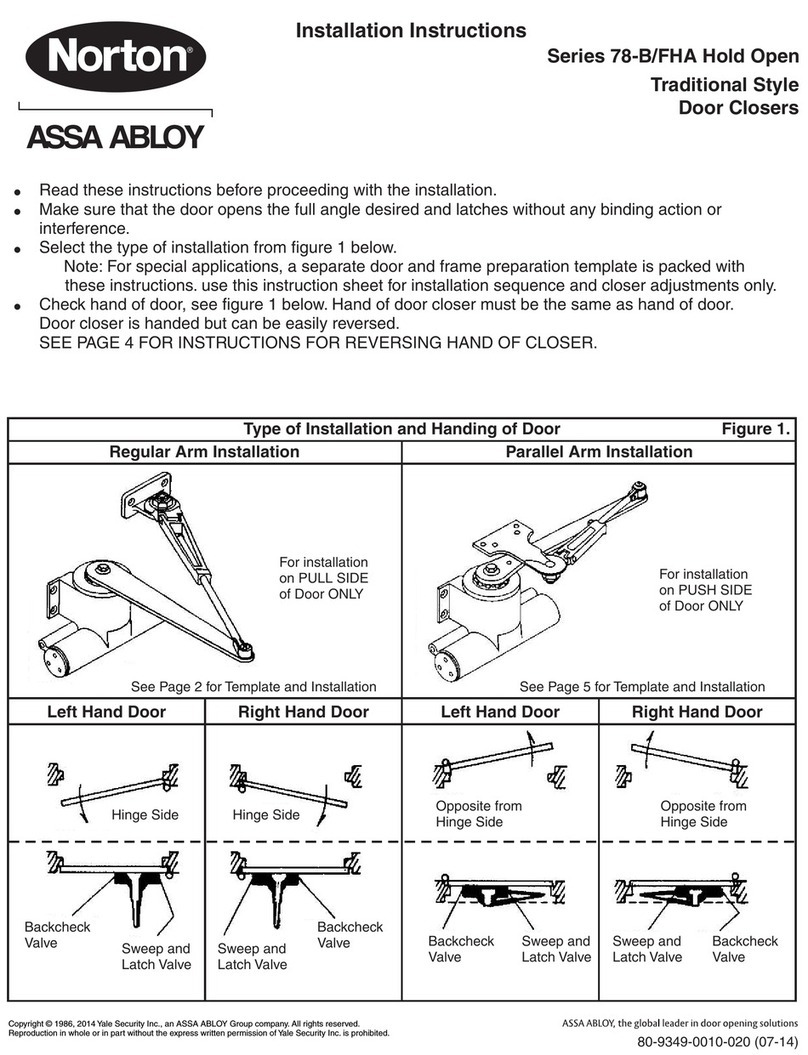

Assa Abloy Norton 78-B/FHA Hold Open Series User manual

Assa Abloy

Assa Abloy DC135 Service manual

Assa Abloy

Assa Abloy Norton 6300 Pull Side Series Quick guide

Assa Abloy

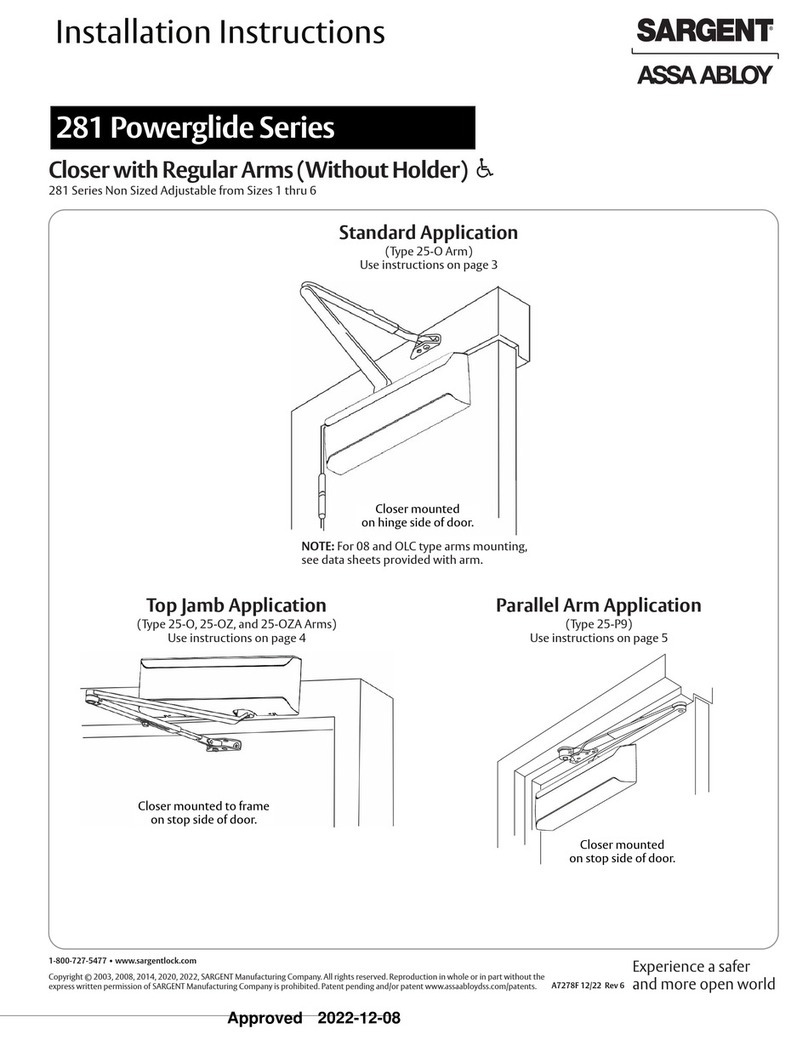

Assa Abloy SARGENT Powerglide 281 Series User manual

Assa Abloy

Assa Abloy DC700G-FT User manual

Assa Abloy

Assa Abloy h.e.s. 9100 Series Manual

Assa Abloy

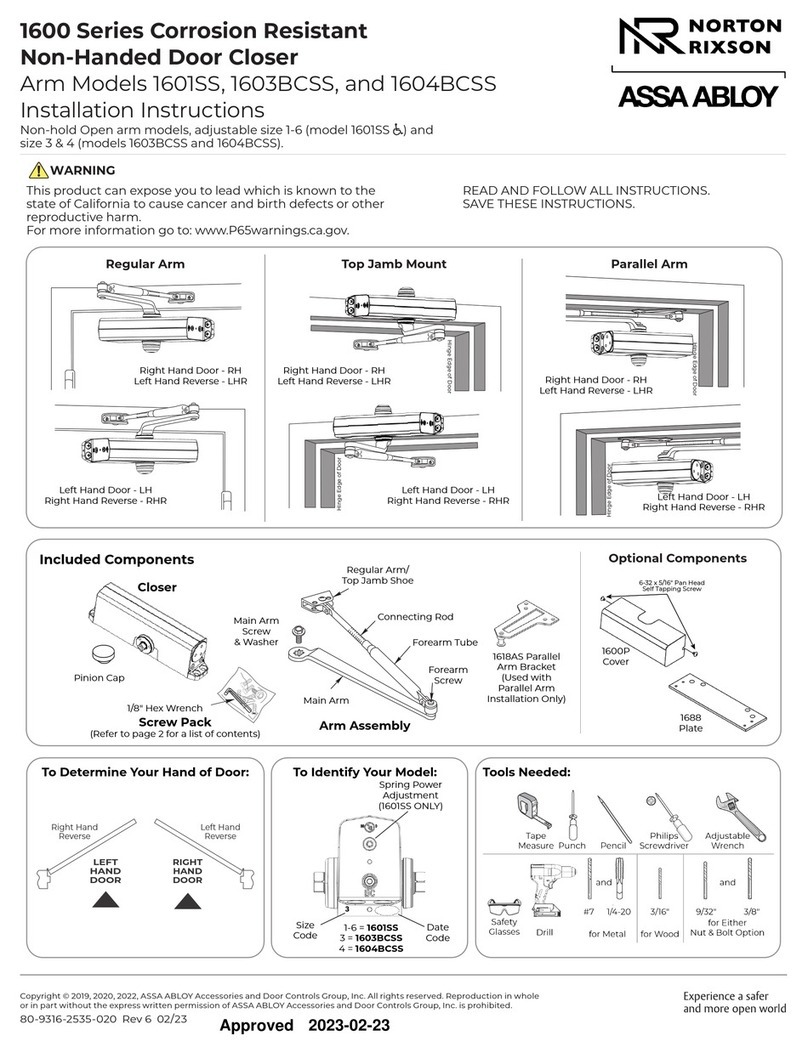

Assa Abloy NORTON RIXSON 1600 Series User manual

Assa Abloy

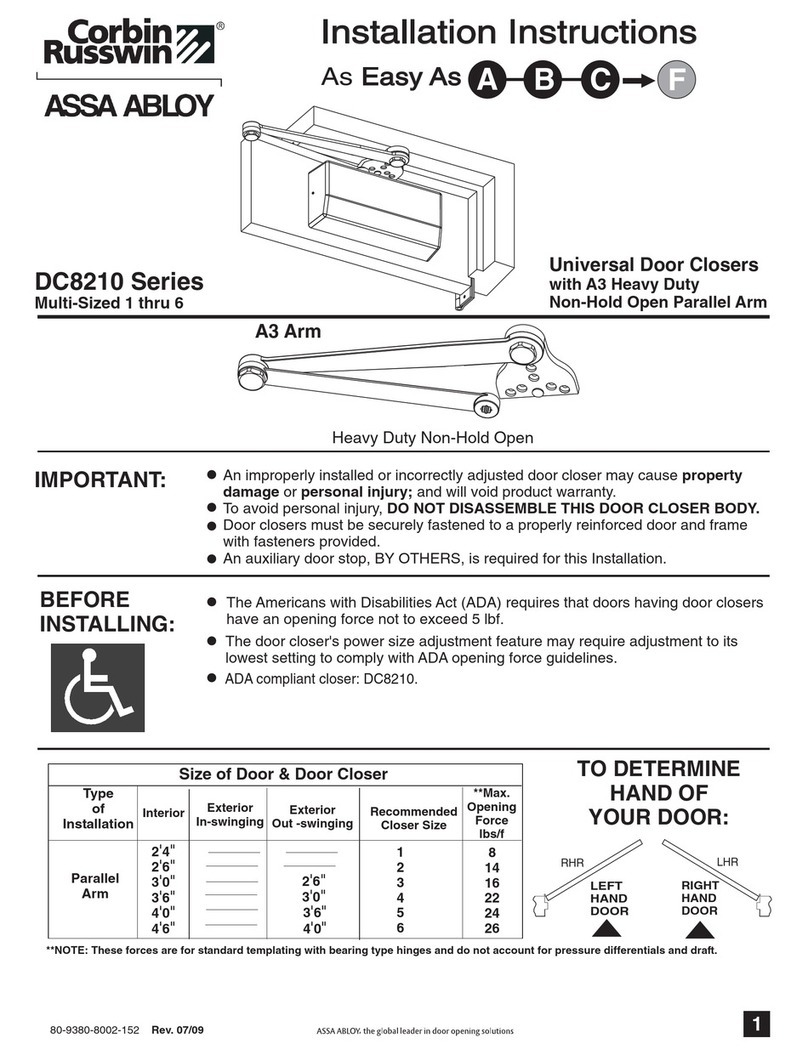

Assa Abloy Corbin Russwin DC8210 Series User manual

Assa Abloy

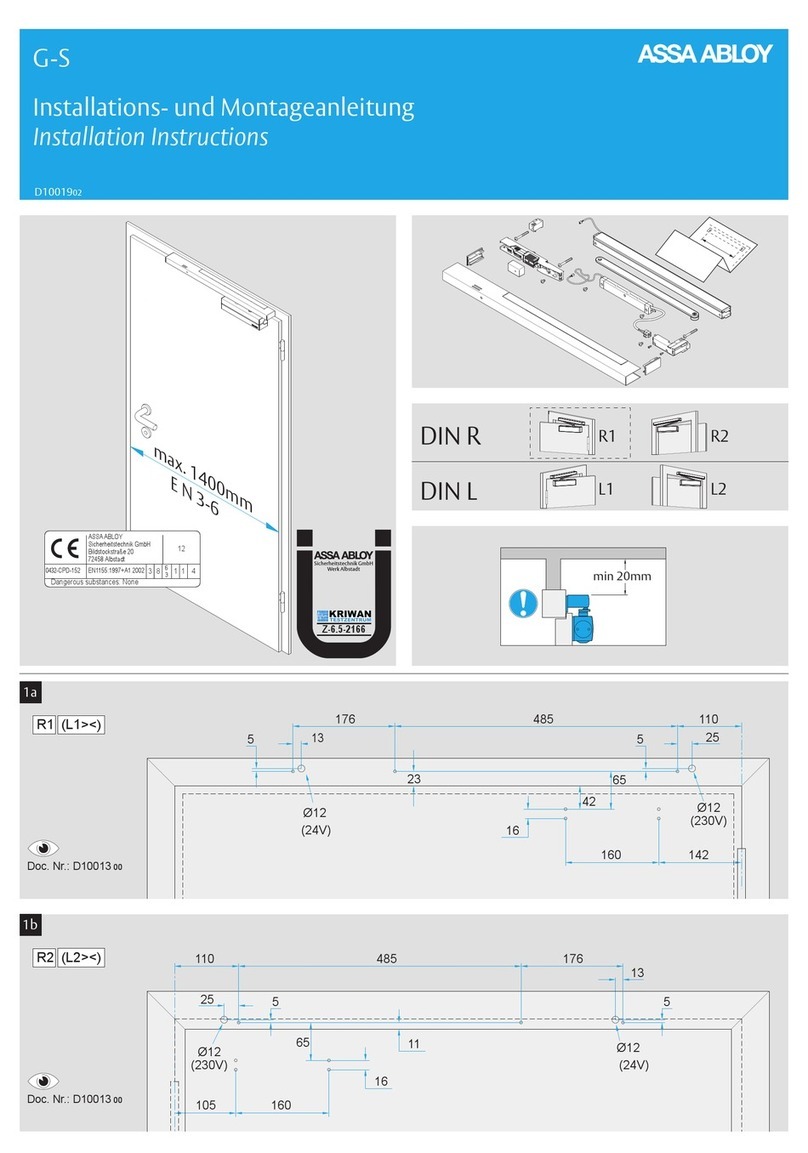

Assa Abloy G-S User manual

Assa Abloy

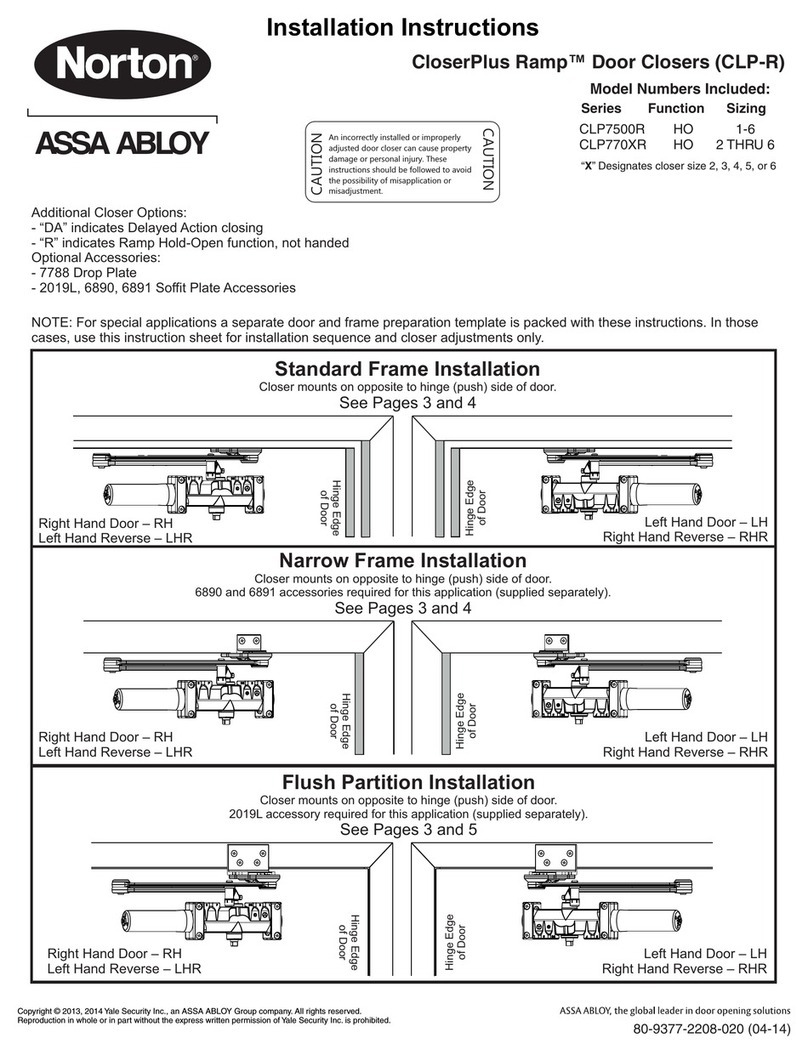

Assa Abloy CloserPlus Ramp Norton XF460 User manual

Assa Abloy

Assa Abloy Corbin Russwin ED5600 Series User manual

Assa Abloy

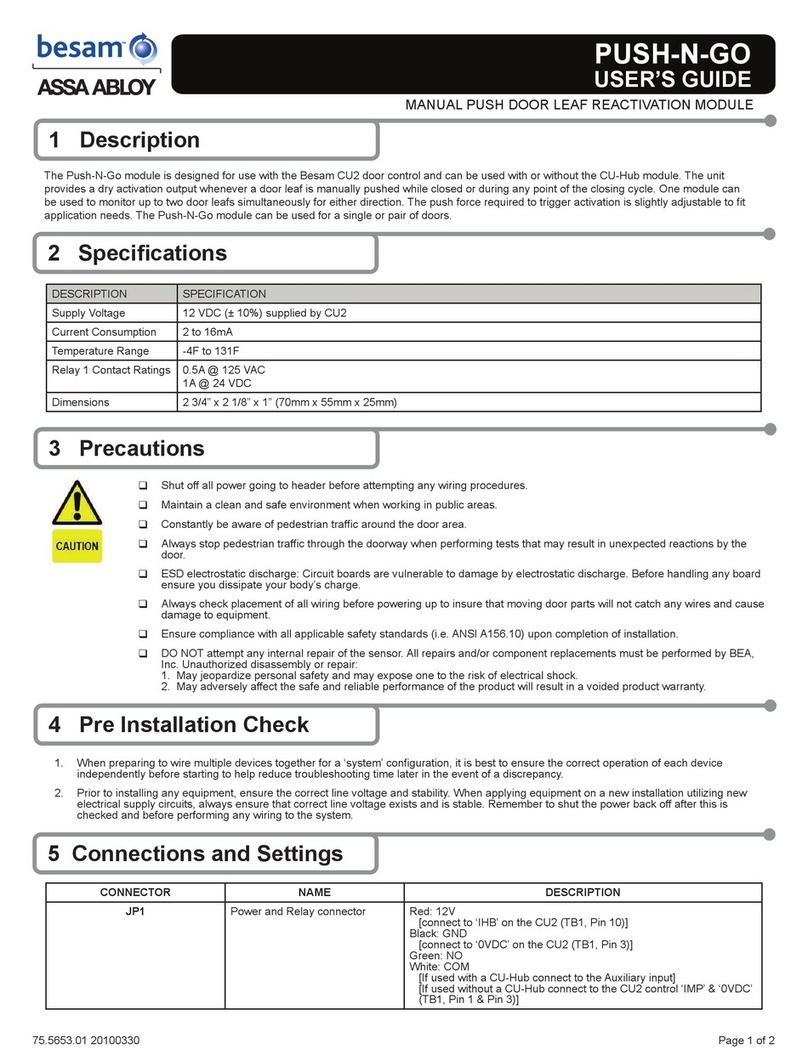

Assa Abloy besam PUSH-N-GO User manual

Assa Abloy

Assa Abloy Rixson Smok-Chek VI Quick guide

Assa Abloy

Assa Abloy Norton 6300 Series User manual

Assa Abloy

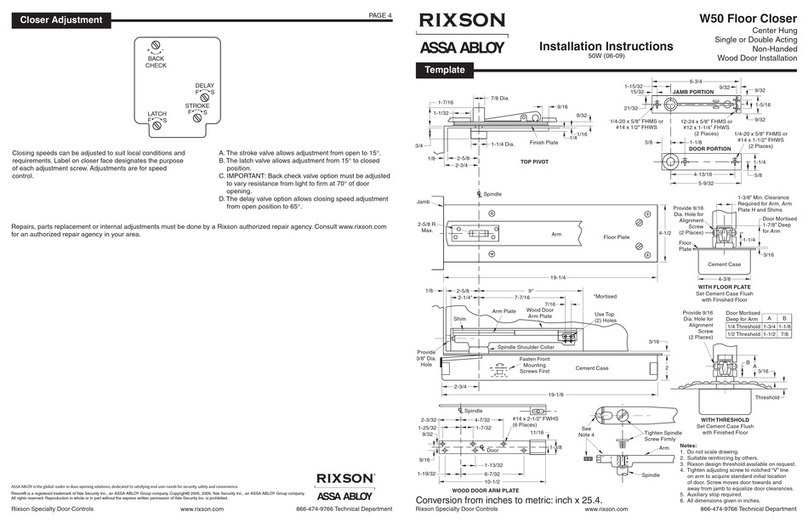

Assa Abloy RIXSON W50 User manual

Popular Door Opening System manuals by other brands

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual

Chamberlain

Chamberlain T user guide