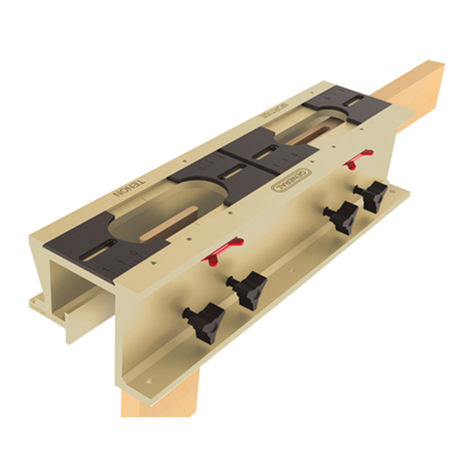

OUT IDE FACE

FIG. 7

3. FIG.7 shows the dimension of the

dovetail joint affected by the

cutter height.

NOTE: Setting this height affects

the length of the Tails and the depth

of the Pins.

4. Now that the router is set up,

you need to reset the Depth

Adjuster Plate

for the length

of the pins. (FIG. 8) Set the

depth gauge for the length of

the “PINS”. This should be

equal to the thickness of the

wood used for the “TAILS”

board. (FIG. 9)

(''!"!'&

Note: Always cut the “TAILS” side of the joint first.

CUTTInG a HalF BlInD DOveTaIl JOInT

1. When cutting a half-blind dovetail joint, using the included

dovetail cutter, start with a bit height setting equal to the

depth of the joint you desire. (FIG. 7)

2. Cut a test joint with scrap wood to confirm the fit of the

joint. If the boards do not fit together easily, the joint

may be too tight. The joint can be made looser or

tighter by setting the cutter depth shallower or deeper

as shown in FIG. 8.

3. Mark the center of your board, then center the mark on

any one of the guide teeth in the “TAILS” portion of the jig.

4. Make sure the outside face of the board faces inwards

towards the clamp.

5. Tighten.

FIG. 9

TAIL

PIN

FIG. 8