NENZ NZ30-01 User manual

NZ30-01 Multi-functional Hammer with DDE

Operating Manual (Professional )

DDE: Dedicated Dust Extraction

Company Profile

NENZ Electric Technology(Dong Guan)Co., Ltd which

focuses on research and development of electric tools as well as

sales and after-sale service of those is one of the high-tech

enterprises. The company is composed of returnees who have

built a powerful team with strong design and development

capabilities, setting up a research and development center,

manufacturing center, marketing center in the forefront of the

world's most dynamic and innovative areas of Dong guan City,

Guangdong Province.

The company concentrates on research and development of all

kinds of its own professional-grade and industrial-grade brand of

power tools, hand tools and garden tools. The main products are

various DC (AC) rotary hammers, demolition hammers, polishers,

sanders, drills, angle grinders, planers, circular saws, cutting

saws, flashlights, chain saws, lawn mowers, etc. The company

pursues innovation constantly, adhering to the developmental

concept "superb technology, quality service and excellence“,

which always sticks to the business philosophy "serving for

customers and creating greater value for customers". It constantly

improves and enhances product quality and service quality. Our

products are widely used in building decorations, common

decorations, high-speed rail construction, shipbuilding industry,

water conservancy industry etc.. To ensure world-class quality

products, the company has introduced all kinds of internationally

advanced detection equipment, and strives to building the testing

center of domestic leading level.

NENZ —— CREATE THE FUTURE!

1

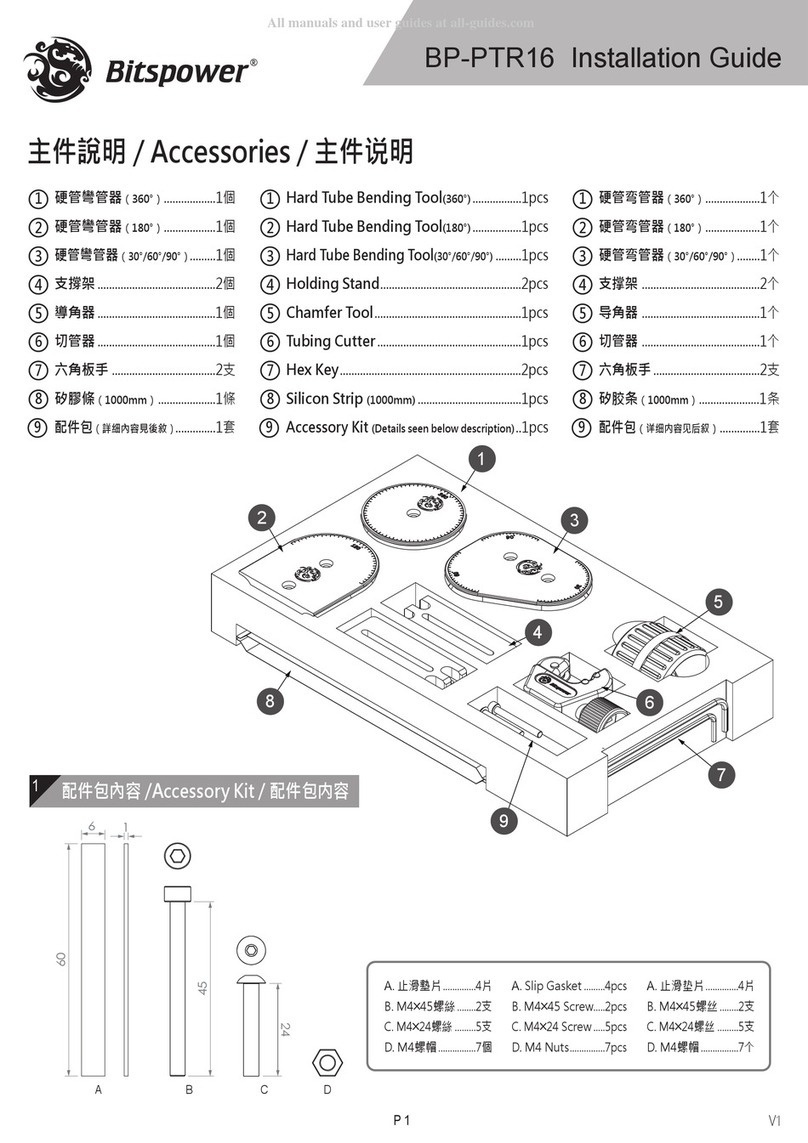

1. Power Input Terminals for DDE 2 .Power Output Terminals for DDE

3. Guide Convex Platform for Hammer 4. Guide Groove for DDE

5. DDE Button for Disassembly 6. Dust Box

7. Button for Dust Box 8 Depth Release Ring

9 Nozzle Top

2

3

1

4

5

8

9

Part Names

6

7

2

Operation

Introduction

s

2.Finished Installation

3

3. Uninstalling DDE

Press the DDE button at the

same time pulling out of DDE.

I. Installing and

Uninstalling DDE

Note: Only if you pull out the bit, you would

disassemble the DDE sucessufully.

DDE bottom should parallel with

that of hammer.

DDE button

1. Installing DDE

1). Rotate the side handle and make

it be in the vertical position of

hammer housing support,

2) .Make the DDE be upright and let

hammer guide convex platform aim

at DDE guide groove.

Operation

Instructions

1. Installing Bits

1).The bit inclinedly insert

into the nozzle top,

2).Then push the bit into chuck

horizontally.

3.Uninstalling Bits

1).Press the chuck and pull

out of bit horizontally,

2).Then inclinedly pull out of

the bit from nozzle top.

2. Finished Installation

II.Installing and

uninstalling Bit

4

Nozzle Top

Chuck

DF

1) Rotate the depth release

ring for unlock,

2)Then move the depth release

ring forward and backword

for setting the drilling depth,

3) Finally Rotate the depth

release ring for lock-up.

III.Setting the Drilling Depth

Operation

Instructions

5

Depth Release Ring

Drilling Depth

Drilling Depth

V. Installing and

Unstalling Dust Box

Operation

Instructions

1). Uninstalling Dust Box

Press two-side button to

pull out of the dust box.

2). Installing Dust Box

Push the dust box into DDE

housing along guide groove.

6

1). Uninstalling Nozzle Top

Press button to pull out of

nozzle top.

2). Installing Nozzle Top

Insert nozzle top into DDE

vertically.

Note: The hair brush and dust shield for nozzle top are wearing parts, For best performance,

you should change nozzle top assembly (including hair brush and dust shield )after you have

drilled 5000 holes.

IV. Installing and

Uninstalling Nozzle Top

Nozzle Top

Hair Brush

Dust Shield

Button

Button

2.After getting out of dust

box, you should dump dust

from the open mouth. If there

is residual dust, please tap its

side place to clean out dust.

Please notice that you must

not knock the top of box and

filter.

Filter shroud

Operation

Instructions

7

Maximum

1. You should tap DDE

housing after drill several

holes and observe whether

dust reaches the maximum

recommended capacity or

not from the transparent

window; if it does, you

must clean dust ,which

can ensure best

performance.

Top of Dust Box

Note: The filter is wearing part. For best performance, please change fliter after

you have drilled 5000 holes

VI.Cleaning Dust

Dust Box

Filter

Dumping Dust

Description:

The DDE is an accessory for use with the NZ30 hammer. The DDE has small size

and light weight, can be quickly and easily attached to the NZ30 hammer.

It is applicable to drill in the concrete materials, it's not suitable for use when drilling

in metal or wood. In order to keep the dust collection effect, please clean the dust of

dust box in time.

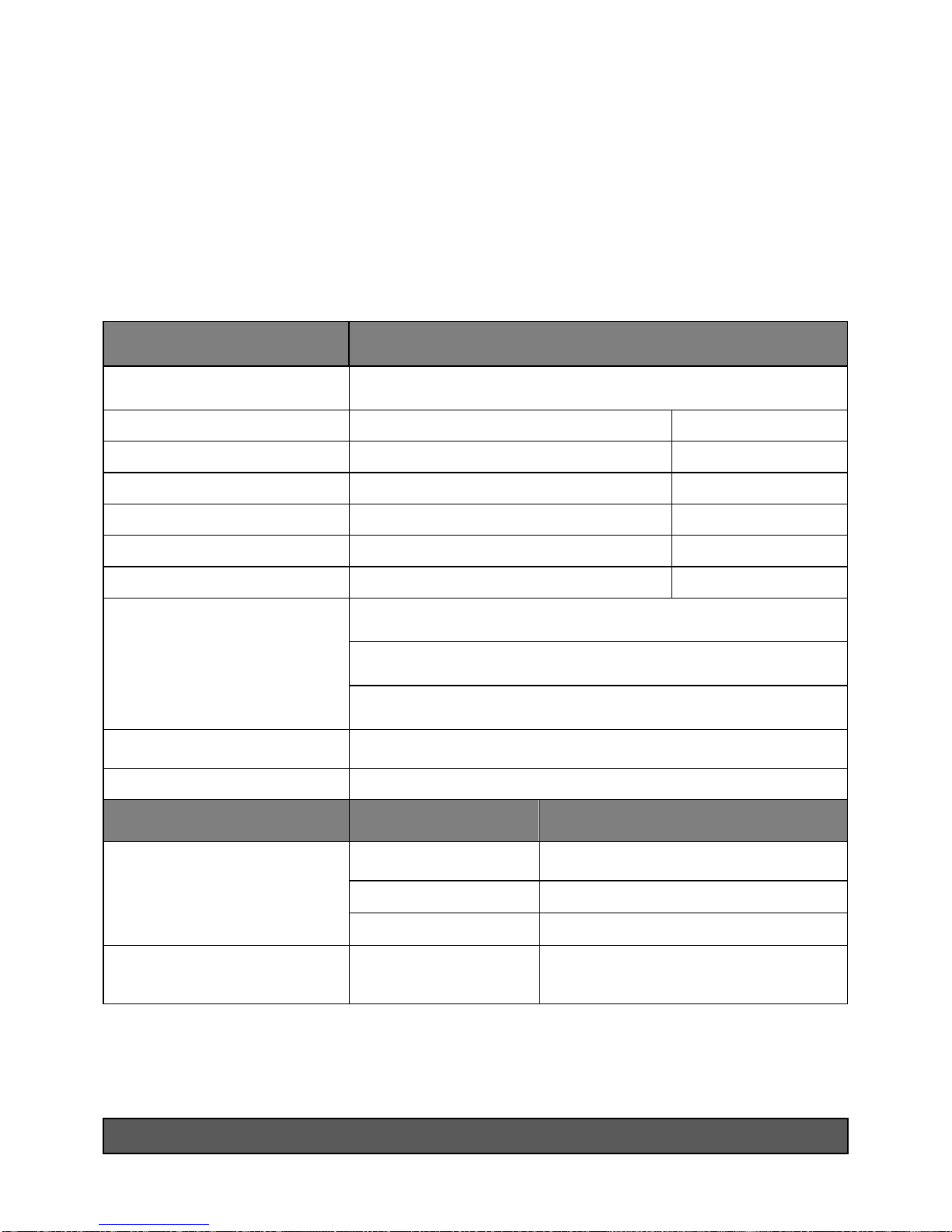

Technical Data

NZ30-01 Hammer with DDE

Production Code

NZ30-01 Hammer with DDE

Rated Voltage

DC 24 V

Voltage

Rated Power

35 W

Watt

Suction Power

10 inH2O

Inch H2O

Weight

0.72Kg

KG

Drilling Hole Depth

Max.84.5mm

MM

Drilling Hole Diameter

Min.Φ6mm~ Max.Φ16mm

MM

Dust Box Capacity

120 Holes(Horizontal drill bit Φ6mm, Depth30mm)

30 Holes (Horizontal drill bit Φ10mm,Depth 50mm)

20 Holes(Horizontal drill bit Φ12mm, Depth50mm)

Filter Capacity

5000 Holes

Nozzle Top Capacity

5000 Holes

Common Problems

Possible Reasons

Proper Measures

1.Dust Overflows

Too much dust in the

dust box

Clean Dust in the Dust Box

Nozzle Top is worn

Change the nozzle top assembly

Hair Brush is worn

Change the nozzle top assembly

2. Bit is not in the center

of nozzle top

it isn't good for

hammer with DDE

assembly

Check hammer with DDE assembly

8

1 SDS Plus Bit(Two Pits ,Two Groove and Round Handle)2 Dust Shield 3 Depth Gauge Rod

4 Button of Depth Gauge 5 Mode Selector Knob 6 Anti-Vibration System 7 F/RButton

8 Trigger 9 Plastic Handle Cover 10 Cord Strain Relief 11 Power Cord

12 Sliding Collar 13 Side Handle 14 Rapid Change Chuck

9

1

2

3

5

8

7

9

10

11

12

13

4

14

6

10

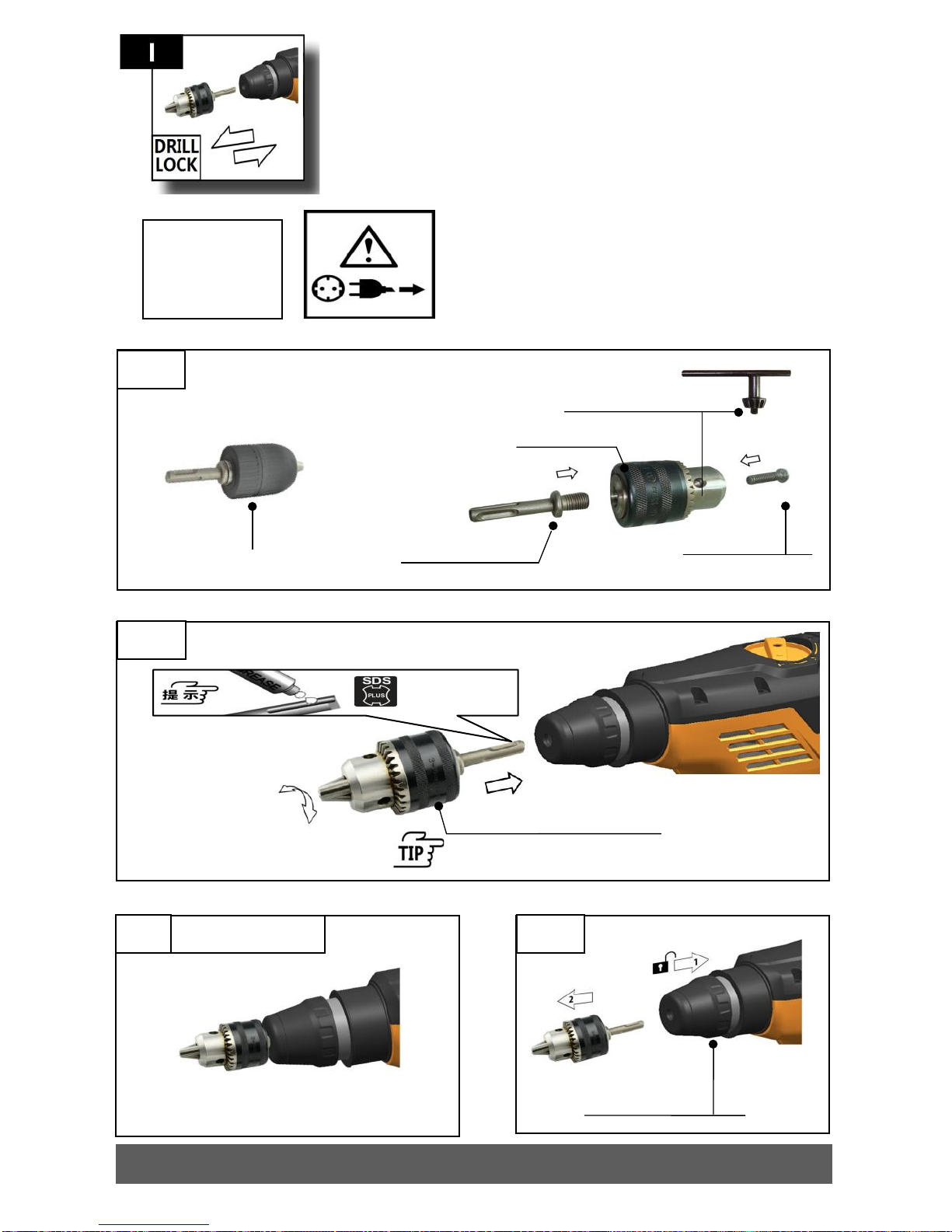

1.

2.

3.

1. Joint Lever

Quickly stick into chuck

4.

Keyless Chuck

Key Chuck

Drill Lock

Assembly

2. Screw connects with lever

Assemble bit by key

Add little

grease

Rotate it when it is inapplicable

Installation Drawing

Press chuck for

pulling out bit

11

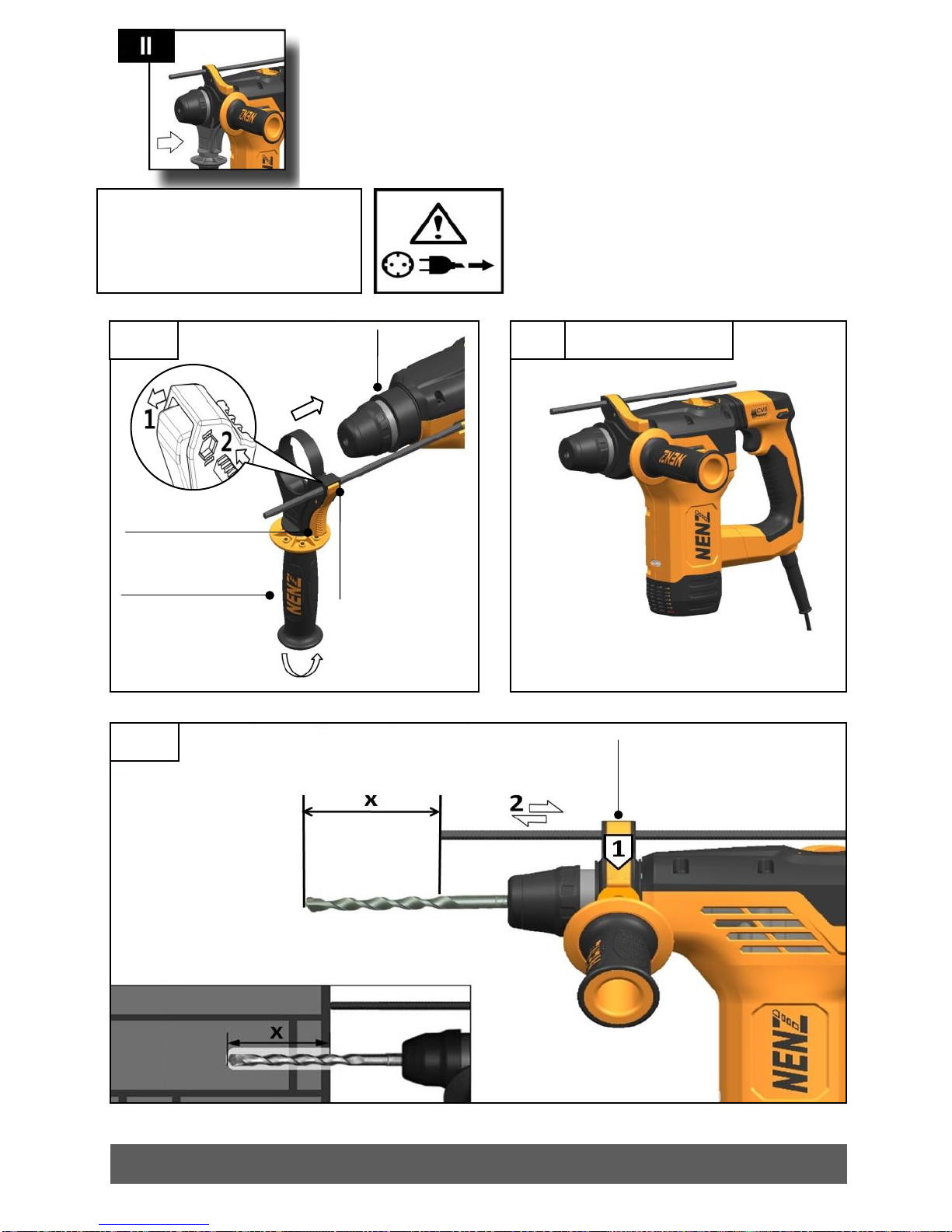

1.

2.

3

Side Handle and

Depth Guage Assembly

3.Assemble it

to the sleeve

Installation Drawing

2. Stick the depth

rod into auxiliary

handle hole along

the teeth direction

1.Press the button

4. Rotate the handle

until lock in the right

position

Press the button for

adjusting drill holes depth

12

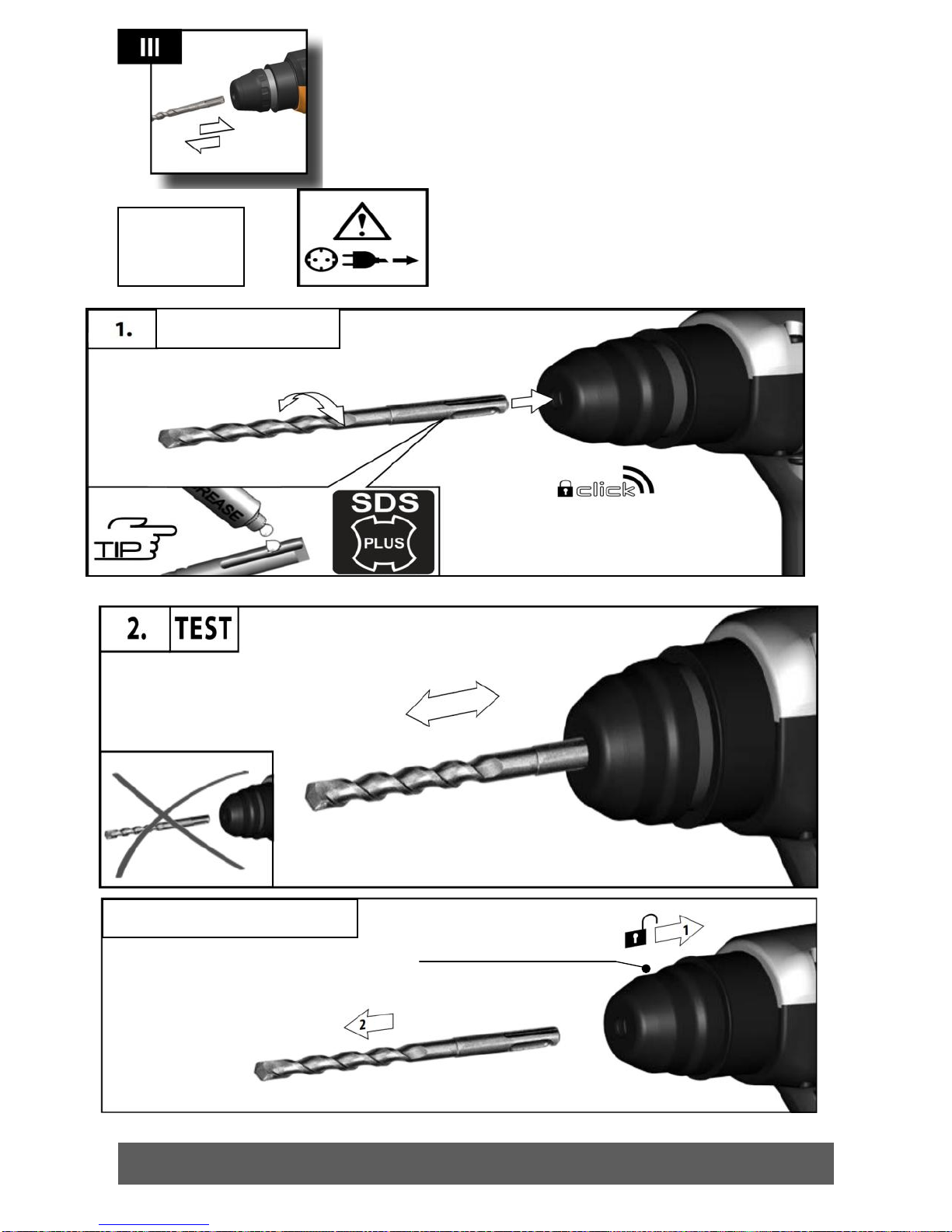

3.

Don't pull bit out

by lock

INSERTING

3. DISASSEMBLE

Bit

Assembly

Add little grease on the

nose of bit, rotate bit

and stick into chuck

Don't pull bit out from

the chuck after the bit

sticked into chuck

Get out the bit while

pressing the chuck

13

Trigger

Operation

h

14

Forward

Reverse

No touching

15

Mode Slector

Knob Operation

16

Too low

pressure

Moderate

pressure

Too high

pressure

Control Vibration System

Technical Data

NZ-30

Production Code

NZ-30

Rated Voltage

220-230 V

V

Rated Power

900 W

W

No-load Speed

0-1500 Min-1

BPM

Blows per Minute(BPM)

0-5000 Min-1

BPM

Impact Energy per Stroke

4 J

J

Wire Cord length

3 m

M

Maxium Drilling Diameter:

- Concrete

30 MM

MM

- Steel

13 MM

MM

- Wood

40 MM

MM

- Light Core Cutter in Bricks and Limestone

82 MM

MM

Chuck Neck Diameter

54 MM

MM

Tool Chuck

SDS Plus

Weight Acocording to EPTA-Produce 01/2009

3 KG

KG

Insulation Class

/ II

/ II

Trigger

Safety Clutch

Forward / Reverse

DDE

Accessories

Drill Chuck

Optional

Drill Bit

SDS-Plus

Soft anxiliary Handle

Depth rod

Nozzle Top with hair Brush and Dust Shield

1

Filter

1

Packing

BMC

0

Tool bag

Instruction Manual

1

17

安全规章

WARNING!

Please read the following safety

warnings and instructions. Failure to

follow them may result in electric shock,

fire and/or serious injury. Save all

warnings and instructions for future

reference. In the following items, it refers

to mains-operated (cord) power tools and

battery-operated (cordless) power tools.

1. Wear Eye Protection .

Please keep on eye protection. Please

use auxiliary handles because loss of

control can cause personal injury. And be

equipped with the safety tools, such as

dust shield, non-slip shoes and safety

helmet. When there is too much noise,

wear eye protection.

2. Workplace and Electric Safety

Keep workplace clean. Prohibit

operating tools in an easily-explosive

environment, such as flammable liquids,

gases and dusts. Avoid direct ground touch,

such as pipe, radiators and ranges. When

operating tools, your hands should hold

the insulation area. Avoid exposure to

rain or damp environment. Prohibit

abusing tools cord. When using tools

outdoor , please use extension cord that is

suitable for outdoor use. If operating

electric tools in a damp environment is

inevitable,use a ground fault circuit

interpreter protected supply.

3. Personal Safety

Stay alert. When operating a power

tool , stay awake. Prevent unintentional

starting. Ensure that switch turns off

when it connected with power supply or

battery pack or when you carry handling

tools. Before turning tools on, remove all

keys or wrench adjustment. Don't

overreaching. Keep proper footing and

balance at all the times. Please dress

properly, don not wear loosing clothes and

jewellery.

Use suitable detectors to determine if

utility lines are hidden in the work area to

avoid electric cables and gas or water

pipes. The dust produced when using this

tool may be harmful to health. Do not

inhale the dust. Use a dust absorption

system and wear a suitable dust protection

mask.

Observe correct mains voltage! The

voltage of power source must agree with

the voltage specified on the nameplate of

machine. Power tools marked 230 V can

also be operated with 220 V.。

The machine is intended for hammer

drilling in concrete, brick and stone, as

well as for lightly chiseling work. It is also

suitable for drilling without impact in

wood, metal, ceramic and plastic.

Machines with electronic control and

right/left rotation are also suitable for

screw driving.

The ventilation slots of the machine

must be kept clear all the time.

Important note:if the carbon brushes are

worn, the tool should be sent to after-sales

service or change them. If the supply cord

of this power tool is damaged, it must be

replaced by a specially prepared cord

available through the service. Use only

NENZ accessories and spare parts. Should

components need to be replaced, please

18

MAINS CONNECTION

SPECIFIED CONDITIONS OF USE

HAMMER SAFETY INSTRUCTIONS

MAINS CONNECTION

SPECIFIED CONDITIONS OF USE

MAINTENANCE

MAINS CONNECTION

Table of contents