6

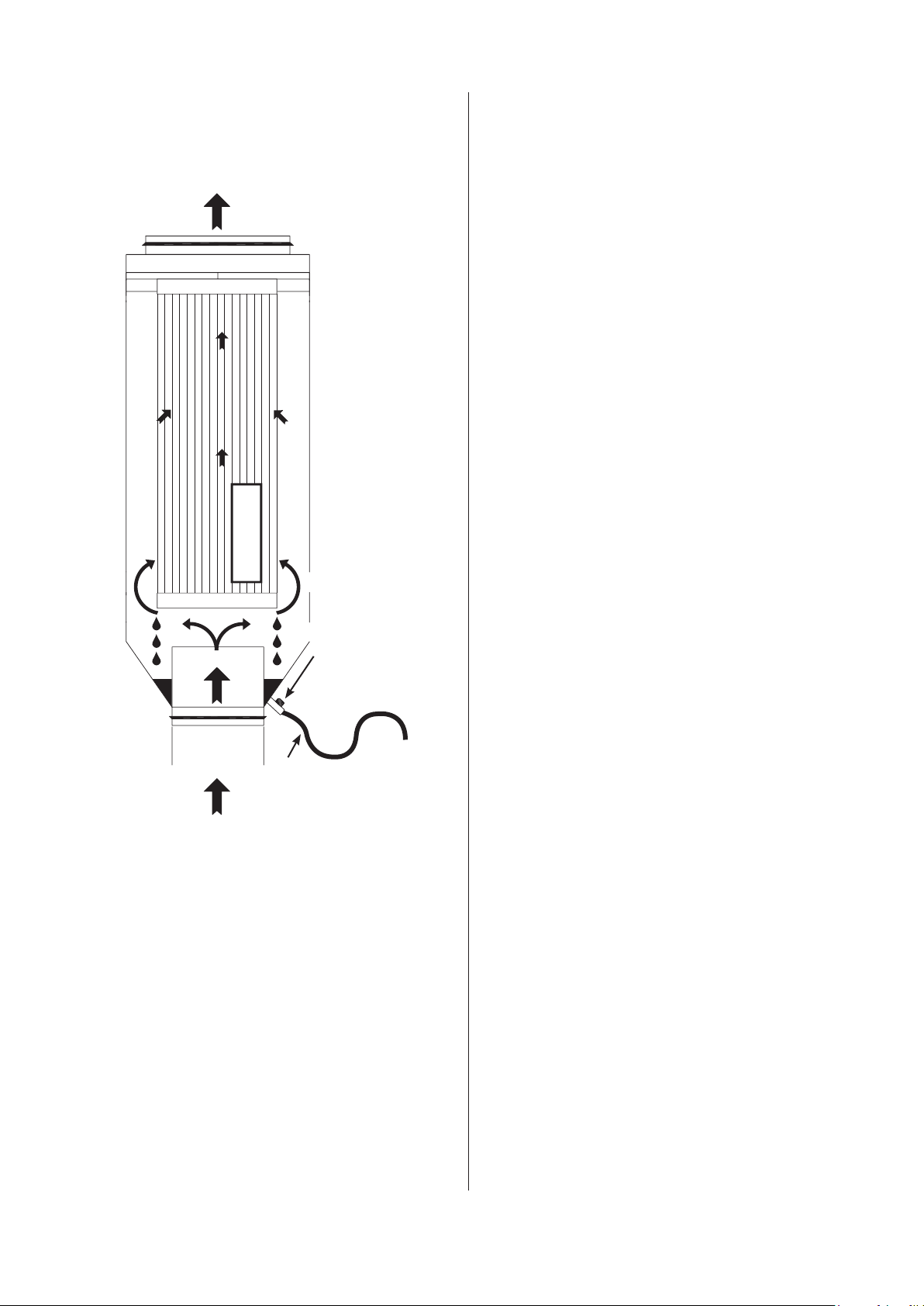

6. The new filter cartridge is carefully placed, (so the me-

dia is not damaged) then mount the top plate and secure

it with the four screws

NB:

Remember to mount the filter cartridge with the opening

facing upwards.

7. The lid is gently moved into place and secured with

the previously removed bolts. Slide the lid down slightly

to make sure it is properly positioned.

8. Put the top plate with the filter cartridge back into the

cabinet. Put the top on the filter and tighten the clamp to

assemble the top and the middle piece.

9. Carefully remove the contaminated filter media and

place it in a large garbage bag for proper disposal accor-

ding to local regulations.

Put the top plate with the filter cartridge back onto the

cabinet. Put the top on the filter and tighten the clamp to

assemble the top and the middle piece.

If you cannot remove the filter cylinder head, the proce-

dure is as following:

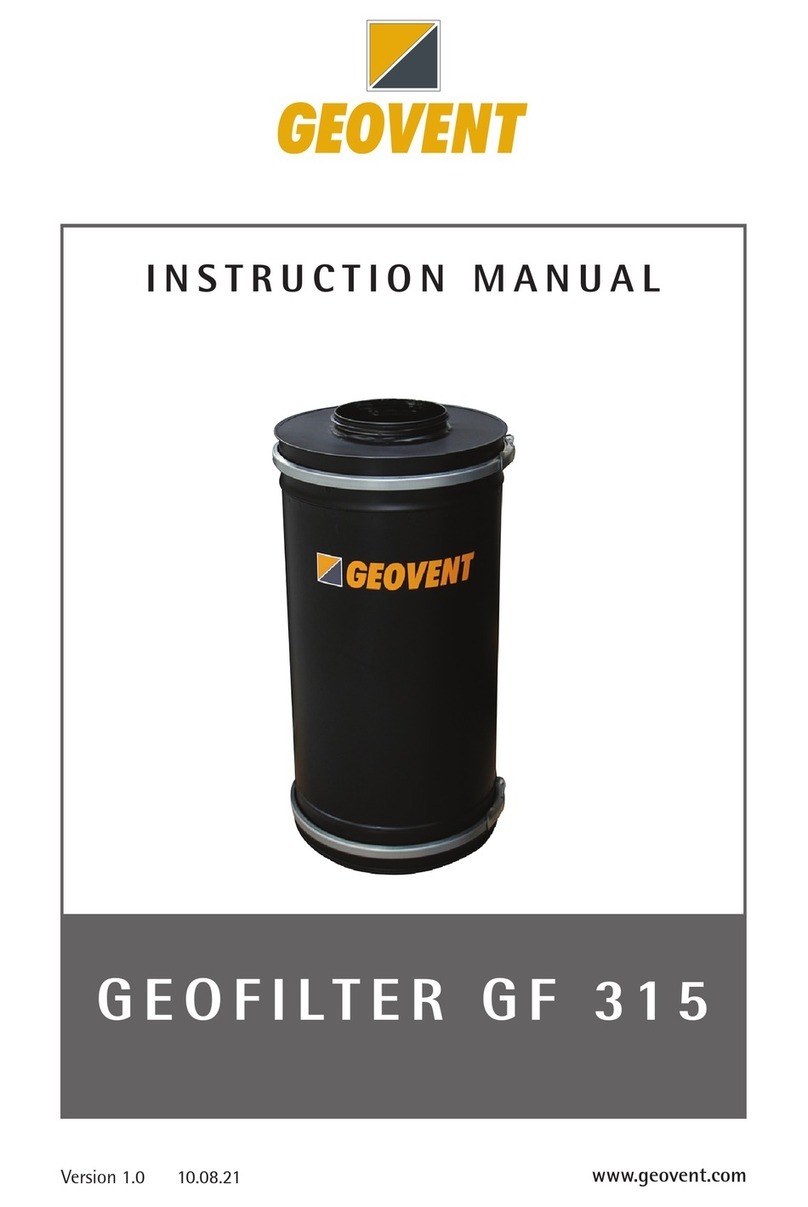

1. Loosen both clamps on the filter as indicated in the

picture below.

2. Remove the middle piece and replace the filter.

NB:

Remember to mount the filter cartridge with the

opening facing upwards.

4.2 Trouble shooting

Problem: The filter does not absorb, as it

should.

Potential solution: Check if the filter cartridge is cor-

rectly oriented. Filter cartridge ope-

ning should be facing up.

Problem: There is not enough airflow.

Potential solution: Check if replacement of the filter

cartridge is due as mentioned in

paragraph 4.1.2.

Replace the filter cartridge, if that is

the case.

Problem: Noise from the filter.

Potential solution:

Check if the filter cartridge is pro-

perly secured to the top plate.

Secure the filter cartridge.

Problem: Oil in the filter reservoir does not

run out.

Potential solution:

Check if grinding dust or metal

shavings Blocks the drain tap.

Clean, if this is the case.

5.0 Liability

Warranty:

Geovent A/S grants a warranty for products, which are

defective, when it can be proved that the defects are due

to poor manufacture or materials on the part of Geovent.

The warranty comprises remedial action (repair or ex-

change) until one year after the date of shipment.

No claims can be made against Geovent A/S in relation

to loss of earnings or consequential loss because of de-

fects on products from Geovent.

Wear parts as fan wheels and hoses are not included in

the warranty.

User liability:

In order for Geovent to grant the declared warranty, the

user/fitter must follow this Instruction Manual in all re-

spects.

Under no circumstances may the products be changed

in any way without prior, written consent from Geovent

A/S.

Moreover, we refer to the current terms of sale and deli-

very at www.geovent.com.