2

1.0 General safety precautions

IMPORTANT- Read the entire manual before installing

and use.

Retain this manual for future reference and instruct all

users in the function and usage of the product.

Do not detach factory tted parts as it will hinder the

operation of the lter.

Power cords and pressure hoses must be replaced

immediately if they are damaged. This work must be

carried out by a trained professional.

All electrical connections must be carried out by a

trained electrician.

1.1 Hazard

Dismounting parts of the Dustbox is associated with

danger.

When tting or servicing the Dustbox, it must be

disconnected completely.

1.2 Area of application

The Geovent Dustbox is used for ltering of

contaminated air from industrial processes such as:

welding smoke, grinding and sanding.

The Dustbox CFU-1000 lter is not to be used in areas

which require the use of ATEX certied products.

The Geovent Dustbox CFU-1000 is supplied with a lter

cartridge. (ltration eciency: min. 99,90% according to

BIA-test.)

Cleaning of the lter is manual. A shot of pressurized

air is sent through the lter cartridge loosening the par-

ticles attached to the fabric of the cartridge.

It is recommended that the lter shot valve is released

after each use. Press the button on the side of the lter

to release the valve.

1.3 Technical specications

Compressed air: Max. 3,5 bar - clean and dry air

Air consumption: 3,0 liter/min.

Power supply: 24VDC el. 230VAC (standard)

Temperature: -12°C - +65°C (extracted air)

Corrosion Class: III

Duct sealing: Class C

Temperature extracted air Max 65°C

Temperature surroundings: -40°C - +40°C

Operating relative humidity: <90%

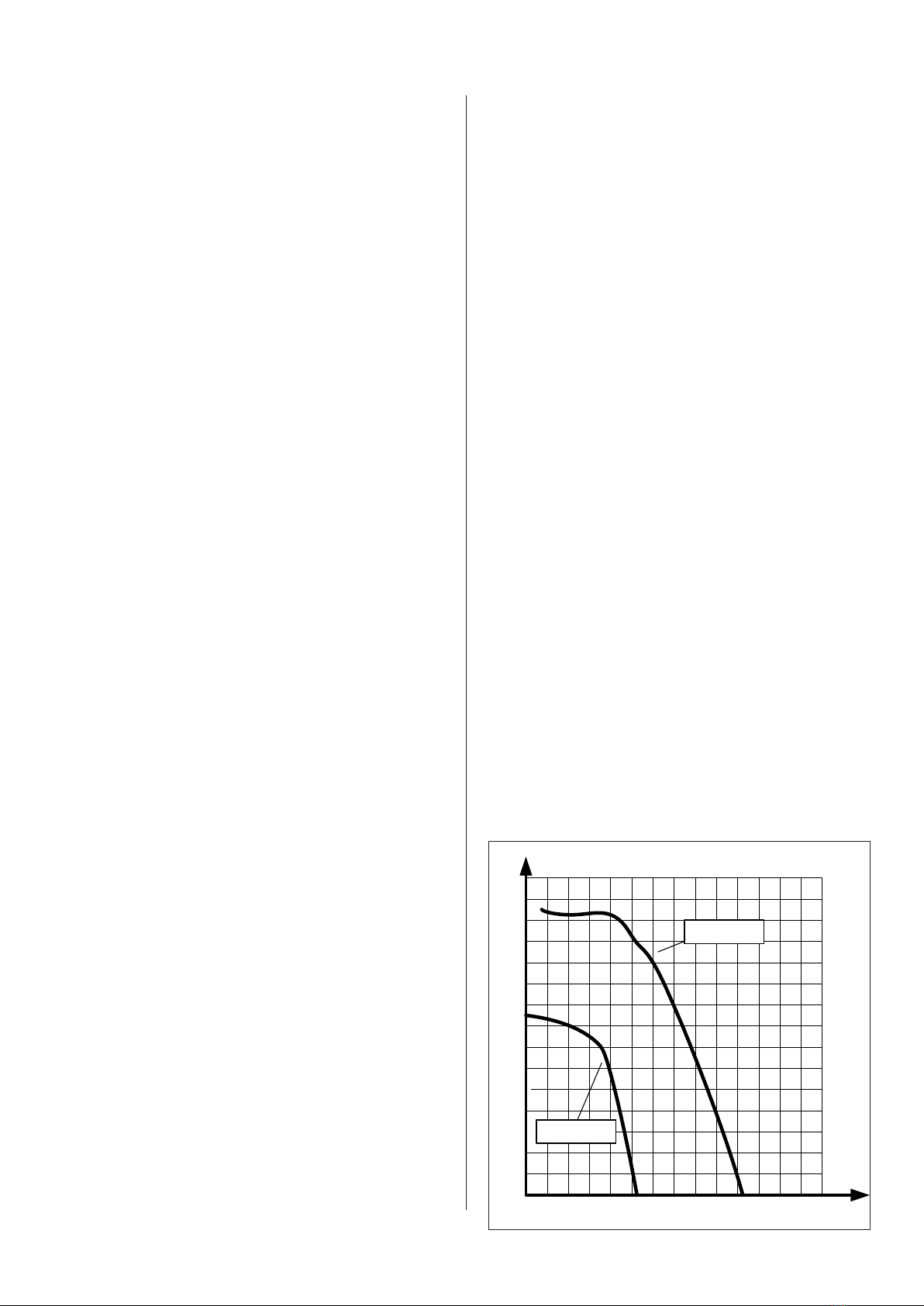

Dierential pressure Geovent Dustbox CFU-1000

Typical pressure drop: 1000-1500 Pa

The pressure drop over the lter will vary according to

work load and how dirty the lter cartridge is.

When the pressure drop reaches 1800 Pa the lter

cartridge must be replaced.

Dierential pressure can not exceed 1.800 Pa.

1.4 Construction

Housing: Warm Galvanized steel.

(Corrosion class lll), with connection.

Compressed air tank: Powder coated steel

Collection drawer: Galvanized – up to 38L

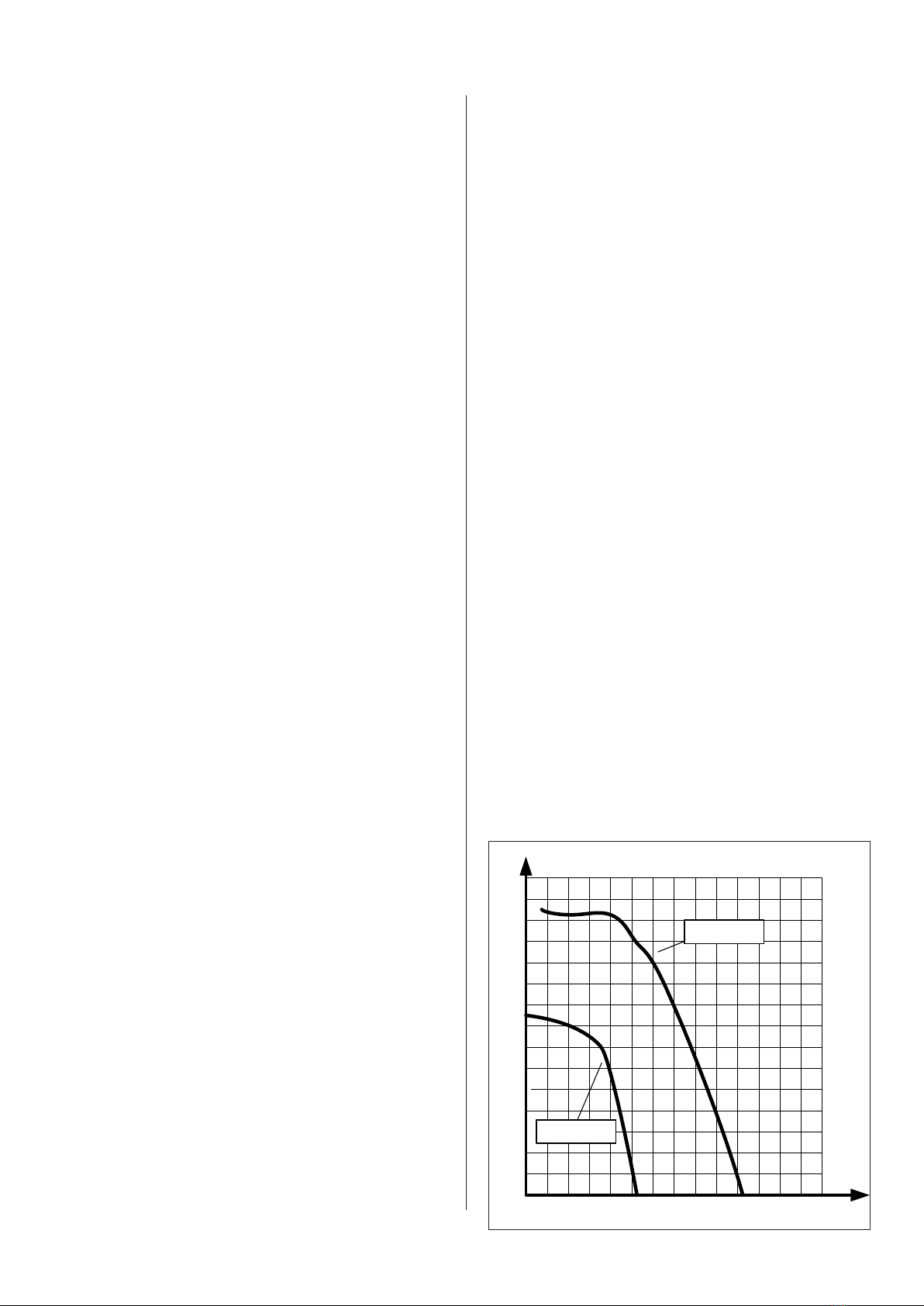

300

250

Flow [m³/h]

[Pa] Fan MHF-400-3

2900 Rpm

500 750 1000 1250 1500 1750 2000 2250 2500 2750

600

900

1200

1500

1800

2100

2400

2700

3000

3300

3600

3900

3000

4200

MHF-500

MHF-400

Index

1.0 General safety precautions . . . . . . . . . . . . . . . . . . 2

1.1 Hazard .................................2

1.2 Area of application ........................2

1.3 Technical specications .....................2

1.4 Construction .............................3

2.0 Installation ...............................3

2.2 Test run- calibration ........................4

4.0 Maintenance .............................4

4.1.1 Emtying the collection drawer ...............5

4.1.2. Replacing lter cartridge...................5

4.1.3. Timer setting ............................6

4.2 Trouble shooting ...........................7

5.0 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.0 Declaration of conformity ....................8