2

Contents

1. Function .................................2

2. Description of elements .....................2

3. Installation ...............................2

3.1 Exchange of the clamping bracket .............2

3.2 Use of the plug-on-rubber....................2

3.3 Installation of the bafe plate

and the dust collecting tray...................3

3.4 Resetting of the pressure switch

for the lter control .........................3

4. Maintenace...............................3

BA_Staubvorabscheidung filtoo_150105_GB.doc 2 15.04.2014

1 Functioning

The spark protection for the unit filtoo can be retrofitted optionally and consists of two components, the

baffle and the collecting tray.

The polluted air is sucked in via extraction elements (e.g. extraction arm) and gets inside the filter unit

via the air intake. There the air hits the baffle plate and is led along the baffle plate towards the collect-

ing tray. At the collecting tray the air deflects by 180°. Thus the air gets into the particle filter. Induced by

the deflection the bigger particles, as for exemple extinct spark particles, fall into the collecing tray and

stay there.

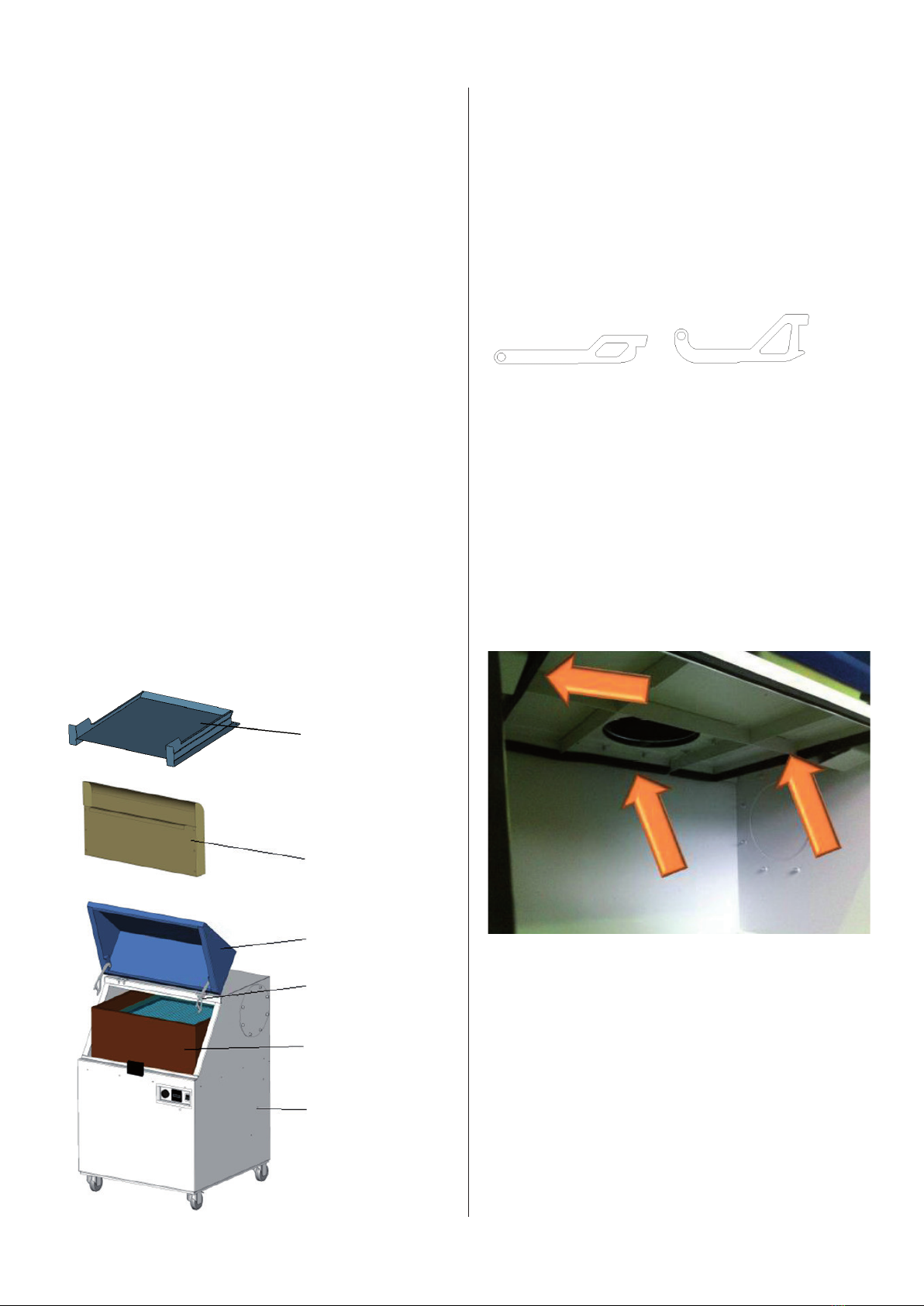

2 Description of elements

Baffle plate

Dust collecting tray

Clamping bracket

Particle filter

Filter unit filtoo

1. Function

The spark protection for the unit W3 can be retrotted

optionally and consists of two components, the bafe

and the collecting tray

The polluted air is sucked in via extraction elements

(e.g. extraction arm) and gets inside the lter unit via

the air intake. There the air hits the bafe plate and is

led along the bafe plate towards the collecting tray.

At the collecting tray the air deects by 180o. Thus the

air gets into the particle lter. Induced by the deection

the bigger particles, as for exemple extinct spark par-

ticles, fall into the collecting tray and stay there.

2. Description of elements

3. Installation

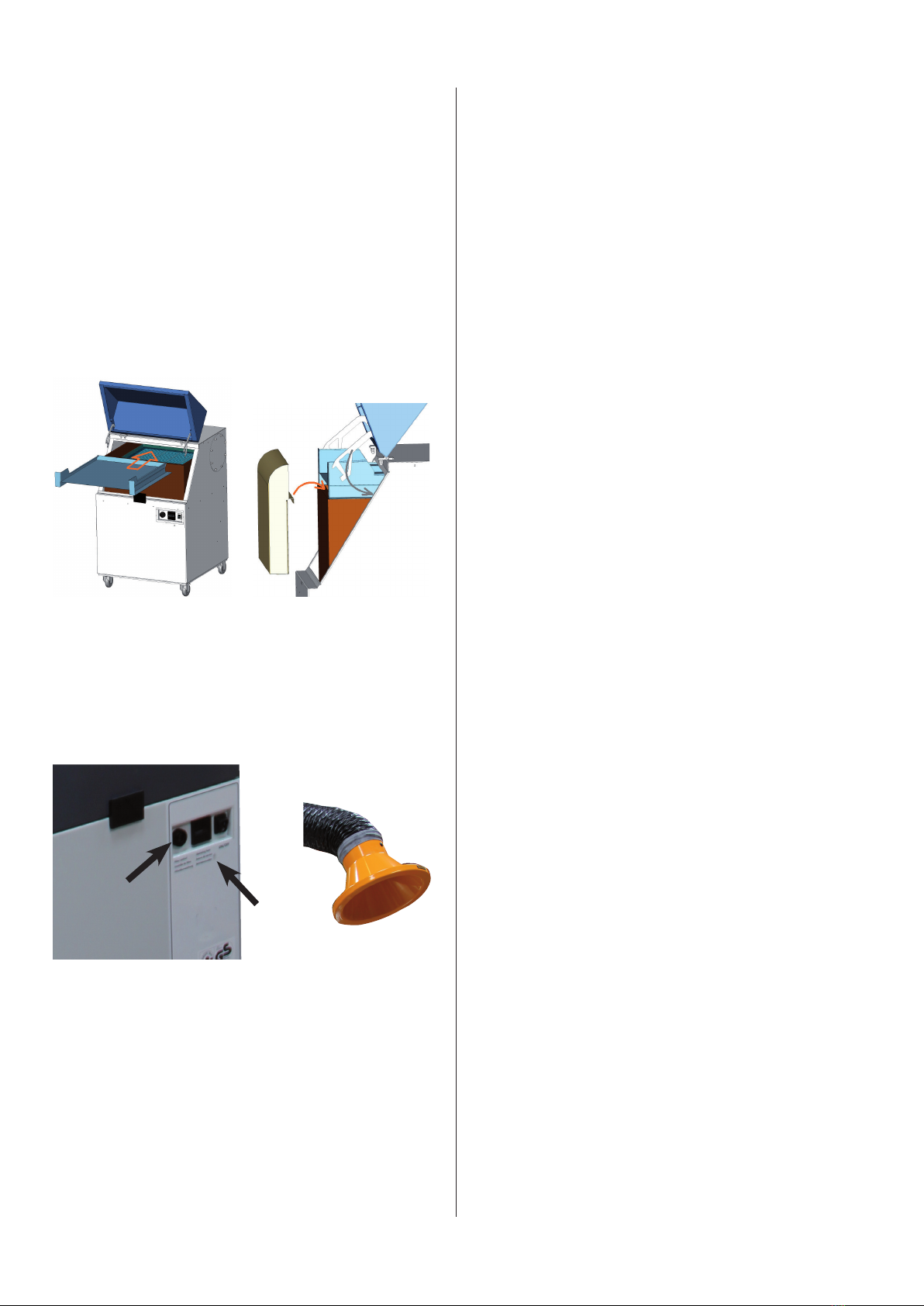

3.1 Exchange of the clamping bracket

The previous clamping bracket is exchanged with the

two new supplied clamping brackets. The shape of

the previously used clamping bracket determines the

choice of the type to be installed.

When screwing the clamping bracket, the screw must

be tightened; but only to the point where the clamping

bracket is still movable. For this purpose it might be

necessary to exchange the screws against the ones

supplied alternatively.

BA_Staubvorabscheidung filtoo_150105_GB.doc 3 15.04.2014

3 Installation

3.1 Exchange of the clamping bracket

The previous clamping bracket is exchanged against two new supplied clamping brackets. The shape of

the previously used clamping bracket determines the choice of the type to be installed.

When screwing the clamping bracket, the screw must be tightened; but only to the point where the

clamping bracket is still movable. For this purpose it might be necessary to exchange the screws

against the ones supplied alternatively.

Shape of the clamping bracket of the filtoo’s till June 2012 Shape of the clamping brackets of the filtoo’s since July 2012

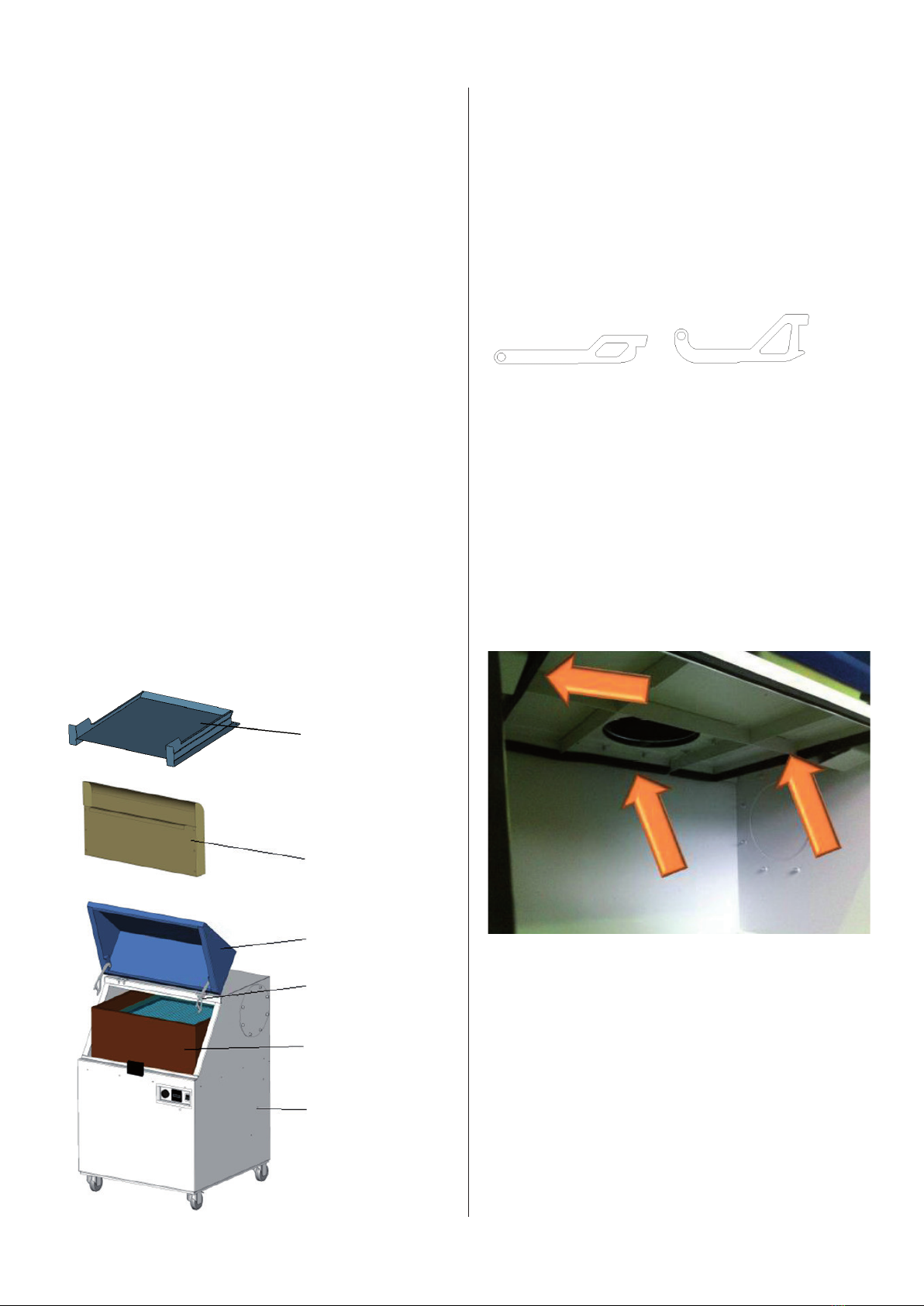

3.2 Use of the plug-on-rubber

The supplied plug-on-rubber is only used with filtoo’s which have been manufactured since end of 2013

(see information on the type plate).

The plug-on-rubber supports the airflow along the baffle plate. Mount the plug-on-rubber at the inside of

the braces (see arrows). At the position where braces cross the plug-on-rubber has to be gashed.

The plug-on-rubber has no sealing function, but reduces the gap between baffle plate and the braces.

BA_Staubvorabscheidung filtoo_150105_GB.doc 3 15.04.2014

3 Installation

3.1 Exchange of the clamping bracket

The previous clamping bracket is exchanged against two new supplied clamping brackets. The shape of

the previously used clamping bracket determines the choice of the type to be installed.

When screwing the clamping bracket, the screw must be tightened; but only to the point where the

clamping bracket is still movable. For this purpose it might be necessary to exchange the screws

against the ones supplied alternatively.

Shape of the clamping bracket of the filtoo’s till June 2012 Shape of the clamping brackets of the filtoo’s since July 2012

3.2 Use of the plug-on-rubber

The supplied plug-on-rubber is only used with filtoo’s which have been manufactured since end of 2013

(see information on the type plate).

The plug-on-rubber supports the airflow along the baffle plate. Mount the plug-on-rubber at the inside of

the braces (see arrows). At the position where braces cross the plug-on-rubber has to be gashed.

The plug-on-rubber has no sealing function, but reduces the gap between baffle plate and the braces.

Shape of the clamping bracket

of the W3 till june 2012

Shape of the clamping bracket

of the W3 till since July 2012

3.2 Use of the plug-on-rubber

The supplied plug-on-rubber is only used with W3

which have been manufactured since end of 2013

(see information on the type plate).

The plug-on-rubber supports the airow along the

bafe plate. Mount the plug-on-rubber at the inside of

the braces (see arrows). At the position where braces

cross the plug-on-rubber has to be gashed. The plug-

on-rubber has no sealing function, but reduces the gap

between bafe plate and the braces.

W3