3.3. This meter has been designed for the hydrocarbon measurement, but with some restrictions regarding to its use with

certain liquids.

The compatibility list is the following one:

• MG-80 is suitable for diesel.

• MG-80V is suitable for diesel, petrol and aviation fuels.

• MGI-80 and MGI-80V are suitable for diesel.

The meters are precalibrated in the factory. IT IS ADVISABLE TO CALIBRATE THEM ONCE THEY HAVE BEEN INSTALLED.

Each liquid type has its own density and viscosity. In order to get a reliable measurement, it is advisable to make this calibration with an approved

test tube or decalitre. It can be used a container, whose capacity you should know previously.

Calibration procedure

6.1. For an exact calibration, the meter, the hose, the nozzle and the pump must be full of liquid, but free of air. This is achieved emptying from 10

to 20 litres of liquid and closing the nozzle, without stopping the pump until the operation is finished.

6.2. Fill the approved decalitre until the exact measurement (10 or 20 litres). The bigger the recipient is, the better accuracy you will have.

6.3. If the quantity does not correspond to the emptied liquid in the recipient, it needs to be calibrated.

The meters are very easy to install. Then it is specified the appropriate process to make the installation more comfortable, using the six possible

combinations to the pipe and hose assembly.

4.1. Check the most right fluid direction. It is not necessary to disassemble the meter to change the liquid direction.

4.2. Take out the chosen inlet and outlet hole plugs, as well as their joints.

4.3. Put these joints and plugs in the holes that are not going to be used. It is not necessary to put other joints in the threads. Everything is foreseen

to get a total sealing. The thread end has a nitrilic joint (or Viton joint according to the model) which guarantees the total sealing with a minimum

pressure.

4.4. It is necessary to use sealing components on the installation pipes and threads, which are resistant to the products to transfer.

3.4. Make sure of the correct installation of the decanting circuit, checking the leak absence.

3.5. It is advisable the assembly of a check valve in the meter outlet. So, it is avoided some problems on the pumping and measuring equipment,

for instance because of an accidental tread on the delivery hose.

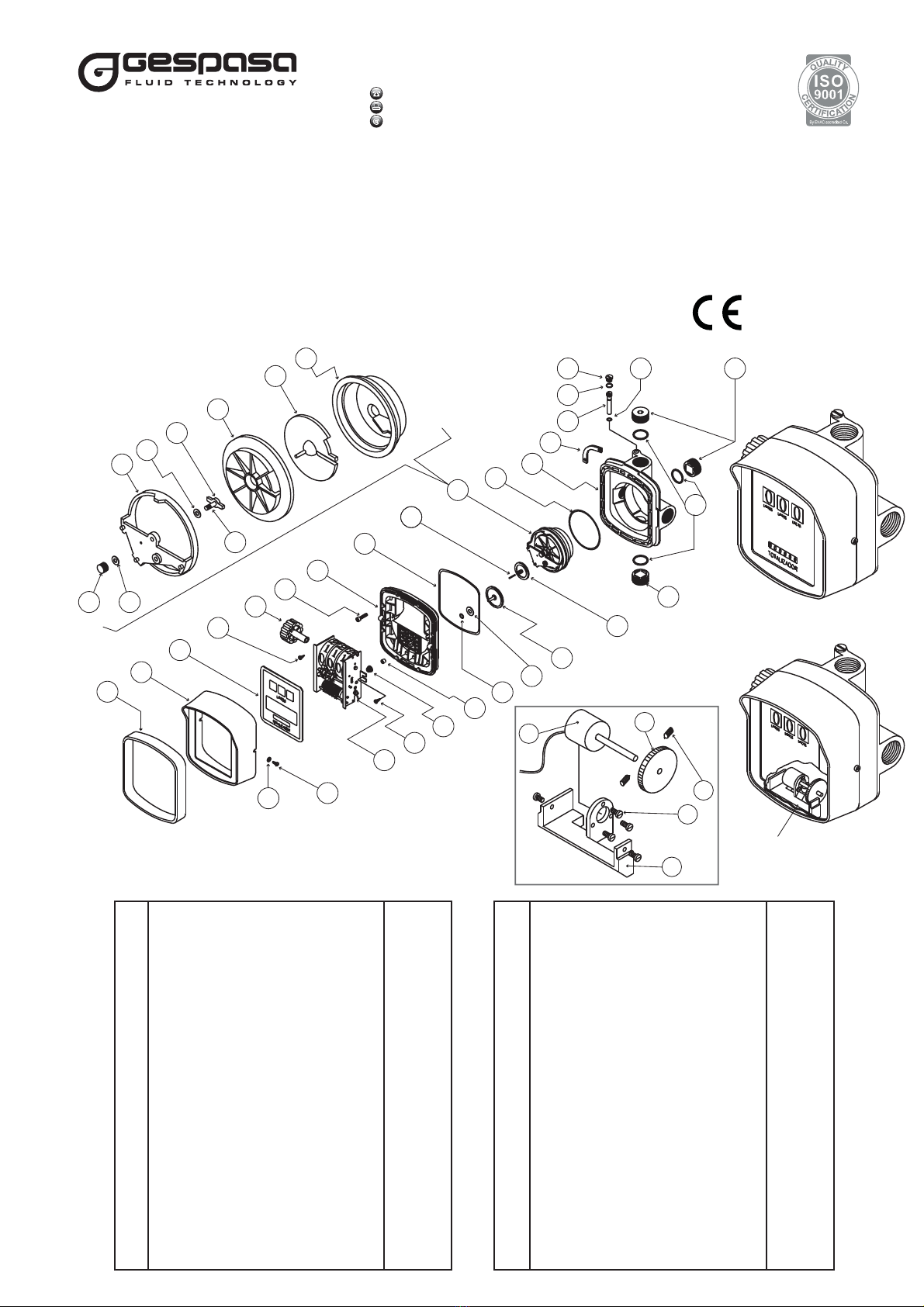

It is not advisable to disassemble the meter, but if you are going to do this, take into account the meter has a measuring chamber with liquid

distributor holes, a partial and a total numeration register. Please see the explosion view section. The meter is divided into parts so that it is easier

to identify each part. Please use the corresponding code number when asking for it, and take into account the meter can be taken into pieces

without disassembling the pipes.

5.1. Take out the lateral reset drive (16).

5.2. Take out the rubber nut cap (12).

5.3. Slacken the two screws (21) and remove the unit numerator cover (19).

5.4. Unscrew the screws (17) that subject the numeration (22) and take it out carefully.

5.5. Unscrew the 8 screws (15) of the central cover (14) from the housing fixation supports (7). When the central meter cover (14) is opened, be

careful because there are the measuring chamber mechanism gears in its inner.

5.6. For its assembly, follow the above described steps in the reverse order, taking into account the correct installation of the housing fixation

supports (7), Viton joint (9) and the special square Viton joint (13).

6.4. First, take out the plug (4) and turn the screw (6) clockwise. Then, the flow percentage decreases. Turning it anticlockwise, it increases. A

complete turn varies the measurement, more or less in 0.4 litres each 10 litres.

6.5. If you want to guarantee a correct calibration, you have to repeat the above step three or four times. If the result is correct, a good adjustment

will be achieved , and the meter will be ready to be used. Do not exceed the pressure of 3.5 bar, and do not work less than 1 bar.

6.6. The MG-80 meter can work by gravity or with a pump. Remember the suitable minimum pressure is 1 bar with a minimum flow of 15 l/min,

and an accuracy of ±1%. If you use it by gravity, it is possible there is some mistake in the measurement due to the different liquid height that the

tank may have. It is always advisable to install a pump.

3.6. IMPORTANT

The meter has a high accuracy because of the minimum tolerances there are in its measuring chamber. It is one of the most

exact meters in the market.

IT IS OBLIGATORY TO INSTALL THE RED ADAPTER WITH FILTER of 350 µm (micron) or the PLASTIC FLANGE KIT WITH FILTER of

350 µm (micron) in the inlet used by the meter in order to avoid the measuring chamber is blocked because of the solid impurities.

IT IS ALSO ADVISABLE to INSTALL the FG-100 MICROFILTER in the pump suction if you want to get a better microfiltration.

4. INSTALLATION

5. DISASSEMBLE-ASSEMBLE

6. CALIBRATION

The calibration process must be done with the nozzle totally open. Never calibrate it with the nozzle mid-opened.

7. MAINTENANCE

The MG-80 meters do not need maintenance. It is possible that some liquids are dried up on the measuring chamber inner, causing an obstruction.

If this happens, they must be cleaned with a lot of care, and when they are going to be mounted, ensure it is correctly done.

If hydrocarbons are used, they can be cleaned with cleaning liquids or oil. Follow the instructions from section 5. Disassemble-Assemble. When

the MG-80 meter is stored for a long time, clean it conscientiously. It will remain protected and ready for a new starting.

WHEN USING THE METER FOR THE ADBLUE/DEF TRANSFER

Due to its chemical composition, the AdBlue/DEF is easily solidified making crystals when it is in touch with the air. These crystals may block the

different mobile parts of the meter. To avoid this characteristic affects to the kit operation, please take into account the following:

If the meter is stopped some days without working, flow demineralized water (preferentially in hot) many times so that the AdBlue/DEF rests are

eliminated and avoid these crystallize in its inner.