10

ECO-TORQUE 280 INSTRUCTION MANUAL

Safety Precautions (con’t)

Safety Precautions Suggestions

Prevent Shank From

Bending

Insert a tool fully into the Collet until it bottoms at the

back of the Collet. Using a tool not fully inserted is

dangerous and can cause the tool to vibrate or the tool

shank to bend.

Tool Precaution Never use tools out-of-round or with bent shanks.

Consistently Tighten

Collet

Periodically check to see that the Collet is fully

tightened. A loose Collet will cause the handpiece to

run slower.

Do Not Use Water

or Oil to Clean

Handpiece

Avoid using the handpiece in water or oil and keep

foreign matter out of the inner casing. This includes

dirt and excessive wood dust. Failure to do so may

result in damage to the ball-bearing assemblies.

Refer to Maintenance for cleaning instructions.

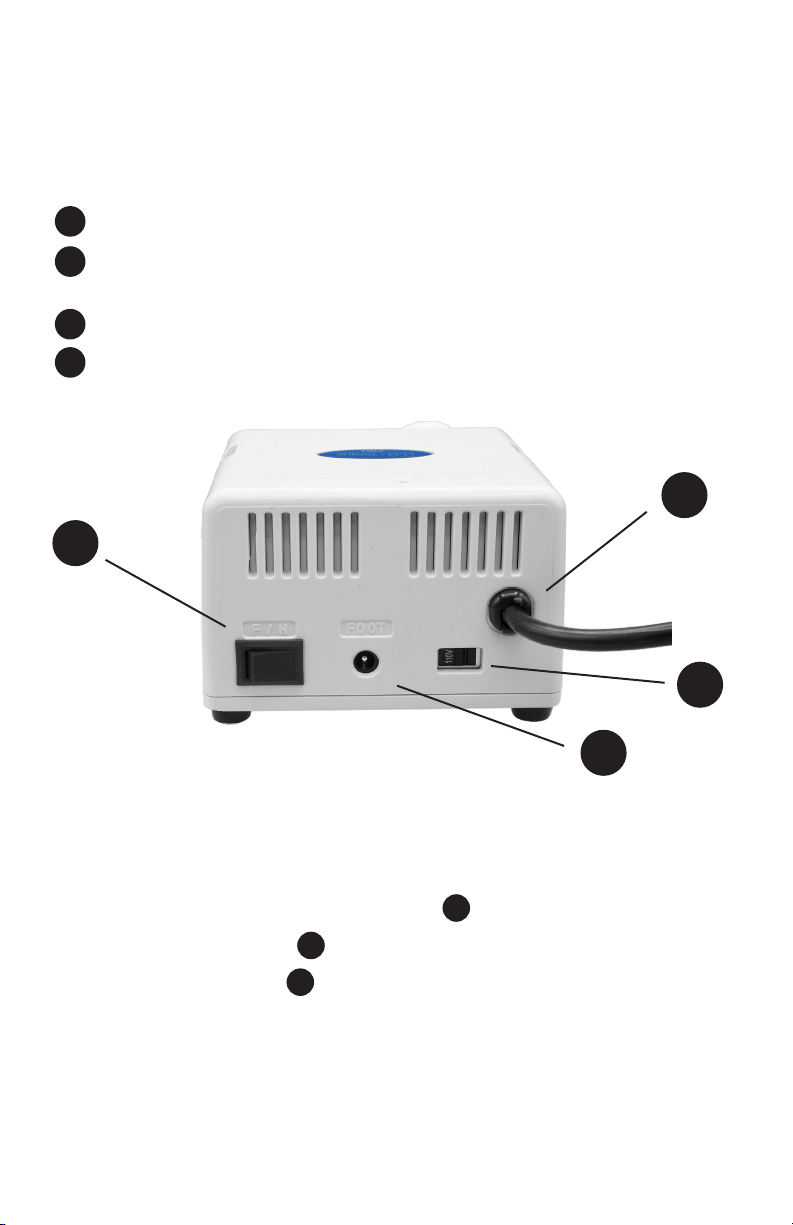

Forward/Reverse

Selector Switch to

OFF

Before operating the Forward/Reverse Selector

Switch, turn the controller OFF. Make the selection,

then turn the unit back ON

Do Not Drop

Handpiece

Take care not to drop the handpiece. Handpiece

bearings may be damaged and tool shanks bent.

Prevent Electric

Shock

To avoid electric shock, never plug or unplug the

Power Cord with wet hands.

Proper Safety

Glasses or Goggles

While operating the handpiece, wear protective safety

glasses or goggles at all times. Eyewear should meet

ANSI Z87.1 and GSA Z94.3 standards.

When Not in Use

Put the handpiece on the rubber cradle rest provided

or into the handpiece holder on the side of the unit.

Put a tool or Test Pin in the Collet when not using the

handpiece.

No Overload

Notication

Please note: there is no overload alert. Overloading

may cause the handpiece to continue until it

stops providing power. To restart, turn o the unit

briey before restarting. Monitor usage to prevent

overloading and damage to handpiece.