2

Contents

Page

Important notes

Usage for the intended purpose...............................................................................................................4

Function..................................................................................................................................................4

Safety note..............................................................................................................................................4

Directives and standards

VdTÜV Bulletin "Water Monitoring 100"...................................................................................................5

Approvals for Marine Applications ...........................................................................................................5

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility)........................................................5

ATEX (Atmosphère Explosible) .................................................................................................................5

UL/cUL (CSA) Approval ............................................................................................................................5

Note on the Declaration of Conformity / Declaration by the Manufacturer ..........................................5

Technical data

NRGT 26-1, NRGT 26-1S.........................................................................................................................6

Scope of supply ....................................................................................................................................7

Name plate/marking ...............................................................................................................................8

Installation

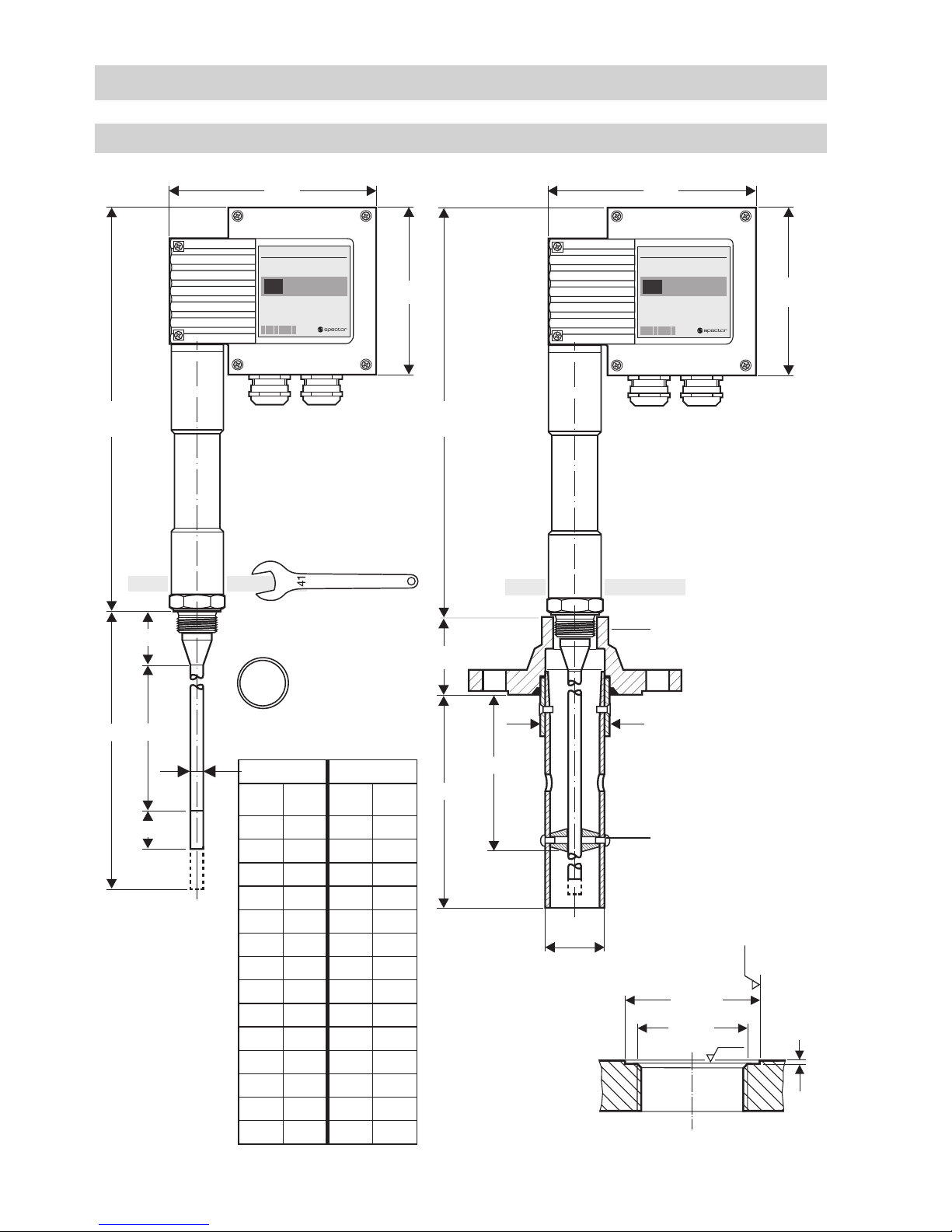

Dimensions NRGT 26-1, NRGT 26-1S....................................................................................................10

NRGT 26-1............................................................................................................................................11

NRGT 26-1S..........................................................................................................................................11

Key .......................................................................................................................................................11

Tools.....................................................................................................................................................11

Examples of installation

NRGT 26-1............................................................................................................................................12

Key .......................................................................................................................................................13

Electrical connection

NRGT 26-1, NRGT 26-1S.......................................................................................................................14

Connection of level transmitter..............................................................................................................15

Connecting the NRGT 26-1, NRGT 26-1S...............................................................................................15

Key .......................................................................................................................................................15

Tools.....................................................................................................................................................15

Wiring diagram for level transmitter NRGT 26-1, NRGT 26-1S ...............................................................16

Connecting level transmitter NRGT 26-.. with supply voltage 24 V AC/DC ..............................................16

Connecting level transmitter NRGT 26-.. with supply voltage 115 / 230 V AC.........................................16

Actual value output ...............................................................................................................................16