5

Explanatory Notes – continued –

Description – continued –

The temperature transmitter TRV 5-40 can be used as:

nsafety temperature monitor / limiter in conjunction with a temperature sensor type TRG 5-6x and

the control unit NRS 1-40.1 / NRS 1-40.2 and

ntemperature monitor & limiter in conjunction with one or two temperature sensors TRG 5-6x and the

control unit TRS 5-40 or any other equipment that is approved for this application.

The equipment combination can be used for monitoring, limiting or control purposes in steam plants

and (pressurised) hot water installations according to TRD and EN 12952 and EN 12953.

Function

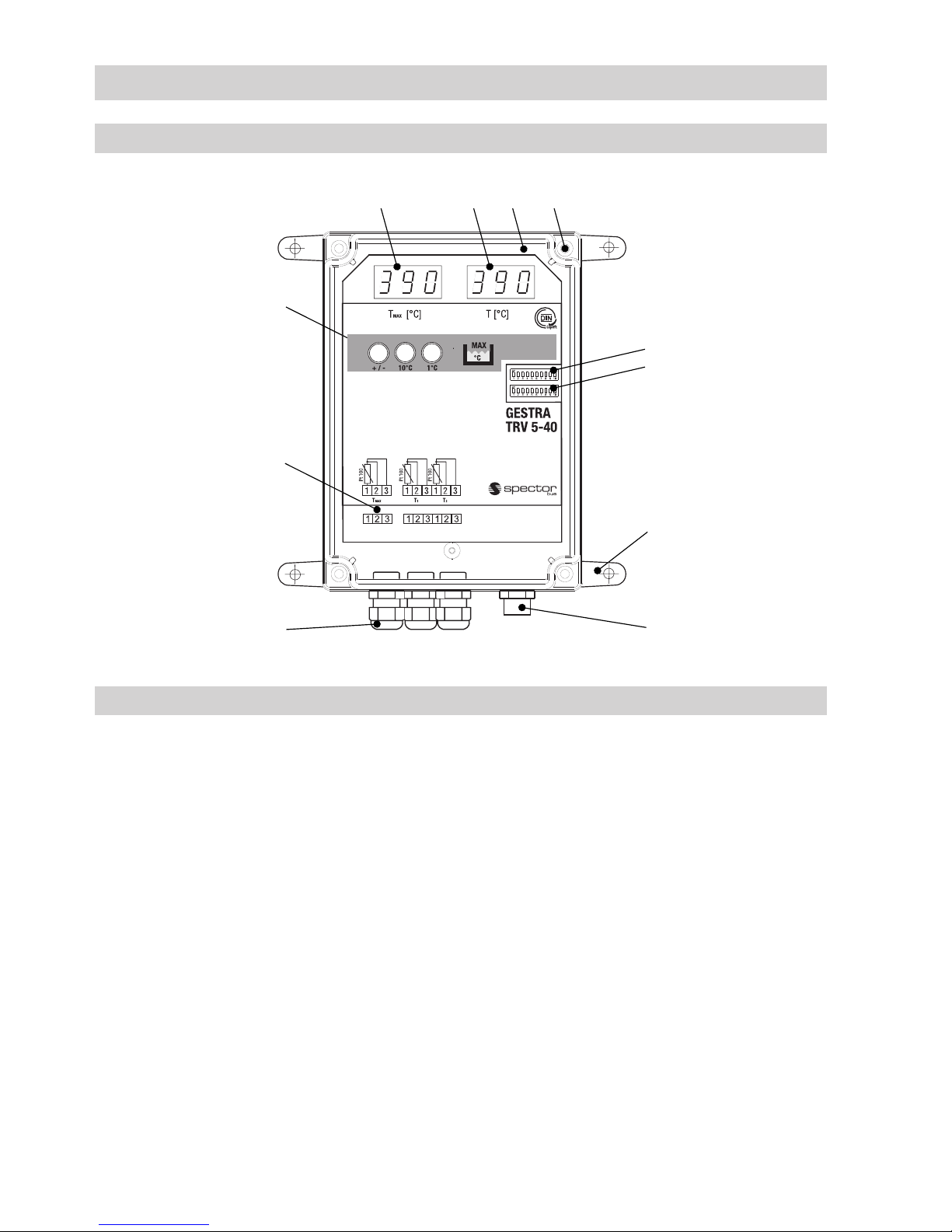

The temperature transmitter TRV 5-40 consists of the safety part for temperature limiting and the part

for temperature monitoring & control.

The safety part is connected with the temperature sensor. The temperature sensor detects the tem-

perature and sends the measured values to the safety part of the temperature transmitter, where the

measured values are recorded redundantly and monitored.

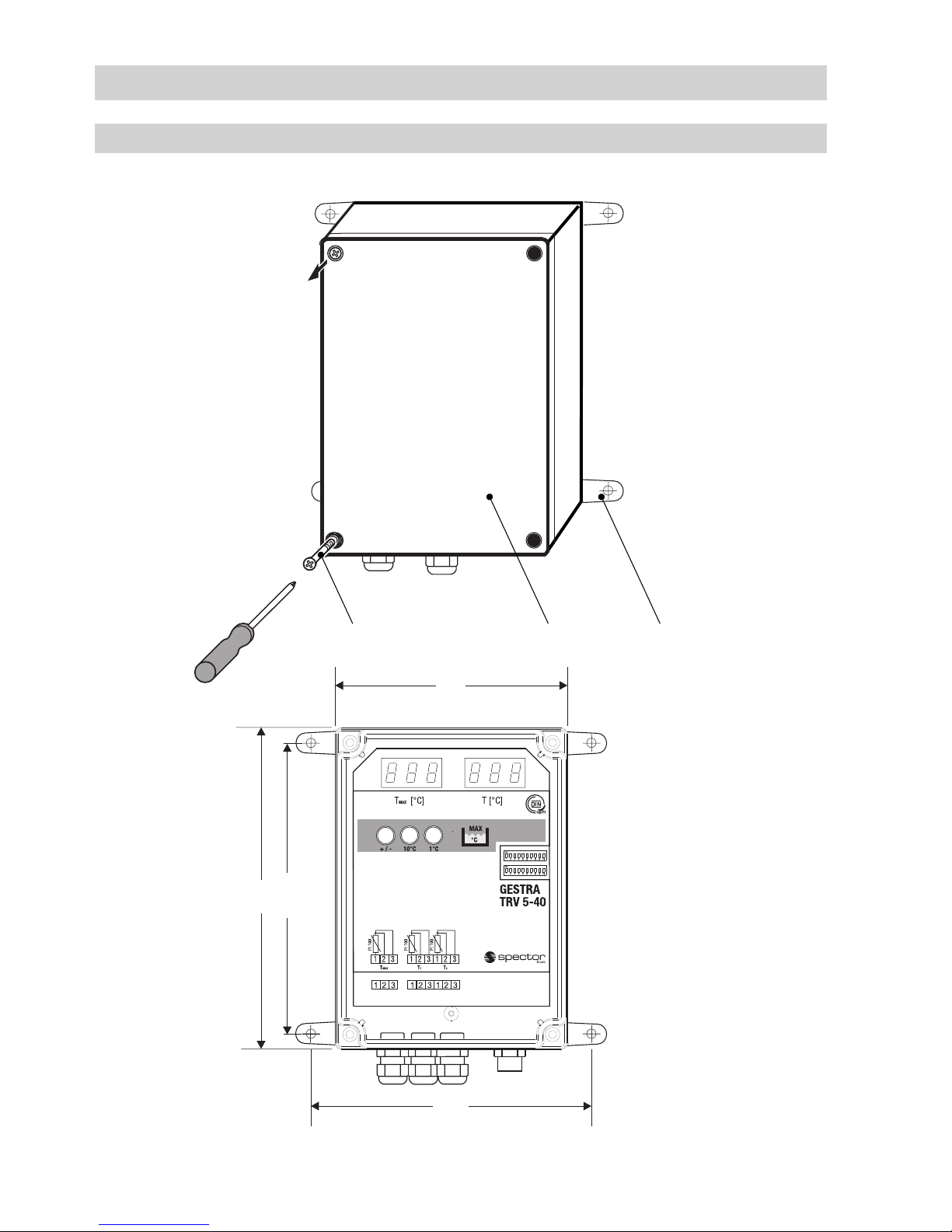

The adjustable temperature limit TMAX (°C), the actual temperature and system malfunctions are

indicated by the temperature transmitter. The temperature sensing element on the electronic insert

monitors continuously the temperature inside the transmitter housing. An automatic self-testing routine

checks every 10 seconds the safety and reliability of the functions of the temperature sensor and the

detection of the measured values.

The actual temperatures, the exceeding of the adjusted temperature limit TMAX (°C), the result of the

periodic self test and the temperature inside the transmitter housing are sent as a data telegram via

CAN bus to the control equipment NRS 1-40.1 / NRS 1-40.2.

Regardless of the safety part two additional temperature sensors TRG 5-6x can be used for tempera-

ture monitoring & control in order to measure further actual temperature values. These readings are

also sent as data telegrams via CAN bus and will be evaluated e. g. by the control unit TRS 5-40.

System components

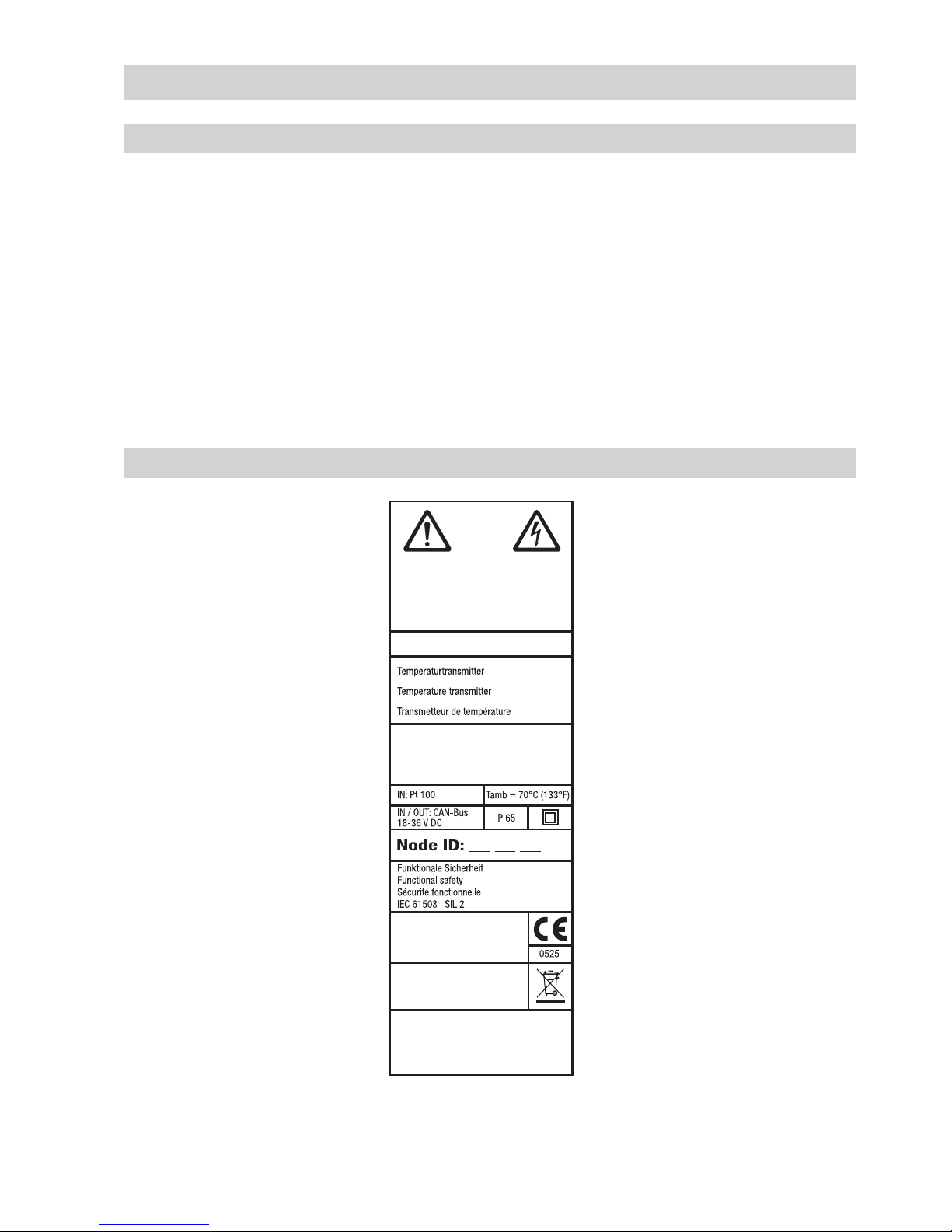

TRG 5-6x

Temperature sensor with resistance thermometer Pt 100

TRS 5-40

Digital temperature switch

Functions: MIN / MAX temperature monitor and temperature controller

Data exchange: CAN bus to ISO 11898 via CANopen protocol

NRS 1-40.1 and NRS 1-40.2

Digital control unit for four sensors (level, temperature)

Functions: Signalling MIN alarm and MAX alarm in freely adjustable combinations

Data exchange: CAN bus to ISO 11898 via CANopen protocol

URB 2

Operating & visual display unit

Functions: Parameterisation, visual indication via LCD display

Data exchange: CAN bus to ISO 11898, with CANopen protocol