61301604052 iii

Table of Contents

SPECIAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . v

WARNINGS SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

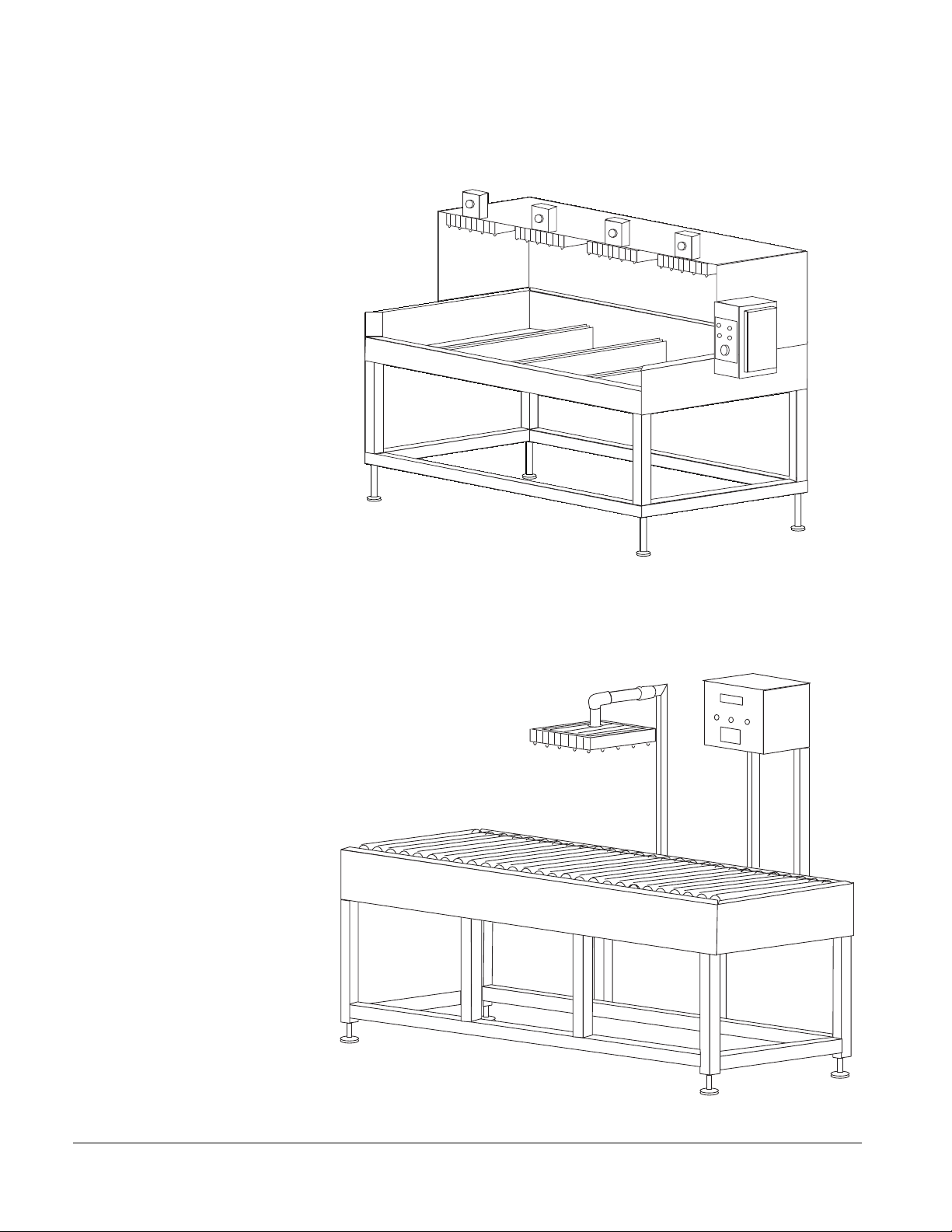

Section 1 General Description

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Optional Standards and Codes . . . . . . . . . . . . . . . . . . 1–3

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Section 2 Operating Instructions

GENERAL MACHINE OPERATION. . . . . . . . . . . . . . . . . . 2–1

1950 Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . 2–1

DAILY CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

END OF DAILY OPERATION . . . . . . . . . . . . . . . . . . . . . . 2–2

EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . 2–2

Shutting Down the Filler. . . . . . . . . . . . . . . . . . . . . . . . 2–2

AUTOMATIC OPERATION (OPTION). . . . . . . . . . . . . . . . 2–3

BOTTLE FILLING PROPORTIONER SYSTEM (OPTION) 2–4

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Section 3 Maintenance

GENERAL MAINTENANCE SCHEDULE. . . . . . . . . . . . . . 3–1

ROUTINE MAINTENANCE SCHEDULE—STANDARD . . 3–2

Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

As Needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

RECOMMENDED SPARE PARTS LIST . . . . . . . . . . . . . . 3–3

Consumable Stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Recommended Spare Parts. . . . . . . . . . . . . . . . . . . . . 3–3

Section 4 Troubleshooting