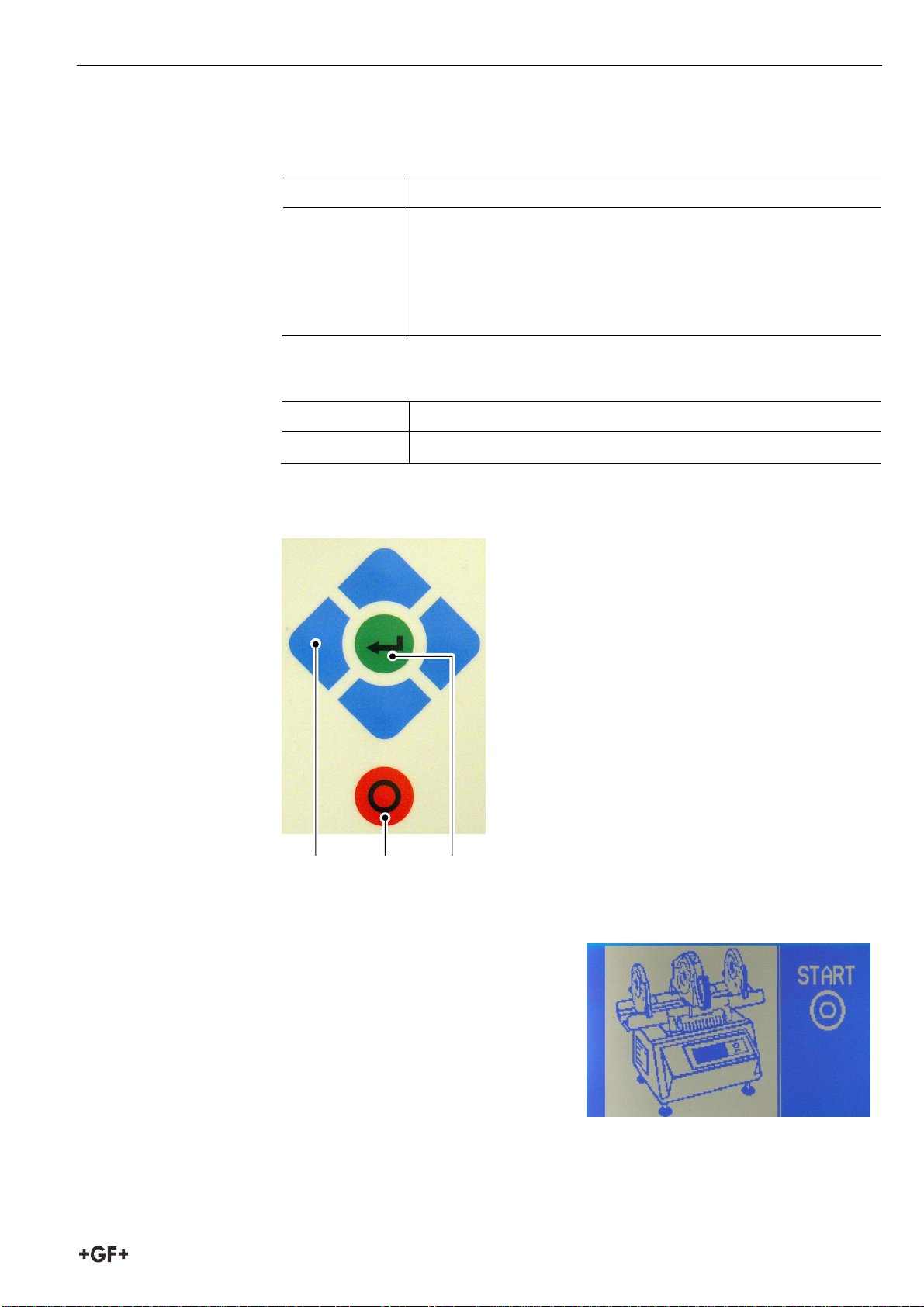

4 Safety information Instruction Manual BCF Plus

(11.15) BCF Plus_BA_04

4

4 Safety information

The BCF Plus fusion jointing machine is a state-of-the-art machine. The

machine may cause risks and danger if it is used improperly or not for its

intended purpose by untrained personal.

Consequently:

Every person working with the BCF Plus fusion jointing machine must

have read the complete Instruction Manual in particular have read and

understood this chapter and set up the BCF Plus fusion jointing machine

accordingly.

Keep the Instruction Manual ready at hand in the mobile working table of

the BCF Plus fusion jointing machine.

Use the machine only if it is in technically perfect condition. Faults and

malfunctions which could impair safety must be remedied immediately.

Ensure that only trained personnel work on the BCF Plus fusion jointing

machine.

Check, at regular intervals, that those working on the machine keep in mind

both safety and the risks involved.

Servicing and repairs

Only technical staff of George Fischer may

open the BCF Plus fusion jointing machine.

set the fusion parameters.

repair the BCF Plus fusion jointing machine.

Use only George Fischer spare parts and accessories.

We wish to explicitly point out that spare parts and accessories not delivered

by us have also not been tested and released by us. Installing and / or using

such pro-ducts, can under certain circumstances, change the constructive

standard characteristics of the BCF Plus fusion jointing machine. The result

can negatively influence active and / or passive safety features. In such cases,

George Fischer will not be held liable nor provide warranty coverage for any

injuries and damages resulting from such installation and use.

4.1 Other Related Documents

Safety Data Sheets for PVDF material

Declaration of Conformity

These documents are stored in the drawers of the machine or are available via

the agency of GF Piping Systems.

ATTENTION