Operatinginstructions PSO701 3 General

5

3 General

3.1 Introduction

This instruction manual was written for those persons responsible for the

operation and care of the PSO 701. It is expected and assumed that

such personshaveread,understoodandwill abide by the manual in its

entirety.

Only with theknowledge contained in thismanual canfaults on the PSO

701 be prevented and trouble-free operation be ensured. It is therefore

imperative that the responsible persons are familiar with this manual.

We recommend that this manual be read carefully prior to putting the

machine in operation, as we are not liable for any damage or

interruptions in operation resulting from failure to comply with this

manual.

Should problems nevertheless arise, please contact the nearest Georg

Fischer Omicron s.r.l representative.

This manual applies only to the PSO 701.

We reserve the right to make the technical changes necessary to

improvethe PSO701 which may result in deviations from the illustrations

and information contained in this manual.

3.2 Range ofapplication

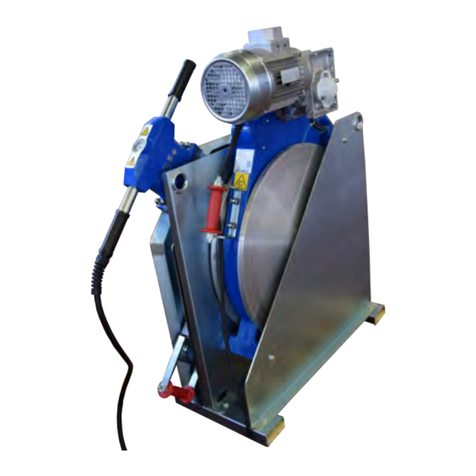

The PSO 701 is designed exclusively

•for the fusion of plastic pipes and fittings

in thedimension ranged 40–160 mm. Any otheruseisnot authorized. The

manufacturer cannot be held liable for damages resulting from

unauthorized use; the user bears sole responsibility.

3.3 Copyright

The copyright for this instruction manual is held by

Georg Fischer Omicron S.r.l..

This instruction manual is intended for assembly, operation and

maintenance personnel. No part of the technical regulations or

illustrations contained herein may be reproduced or distributed in any

form, used illicitly for competitive purposes or passed on to others.

GeorgFischer Omicron S.r.l

Via E. Fermi, 12 - 35030 Caselle di Selvazzano

Padova (Italy)

Telephone +39 049 8971411

Fax +39 049 8971410