HD402… - 3 - V1.1

1INTRODUCTION

The HD402… series is composed of pressure transmitters and pressure ON/OFF relay

switches. The instruments measure relative pressure with respect to atmosphere or

differential pressure in the range from 50 Pa to 200 kPa depending on model) by us-

ing a silicon piezoresistive sensor with high accuracy and temperature compensation,

which allows excellent linearity, repeatability and stability over the time.

Thanks to the particular sensor used, the instruments are insensitive to the mounting

orientation and position. Moreover, the high stability of the sensor over the time and

in comparison to the changes in temperature allows eliminating the operations of

maintenance typically required to compensate for the aging and the deviation of the

sensor zero. The auto-zeroing feature in the HD402TR1L low range model allows sta-

ble measurements over the time without the need to recalibrate.

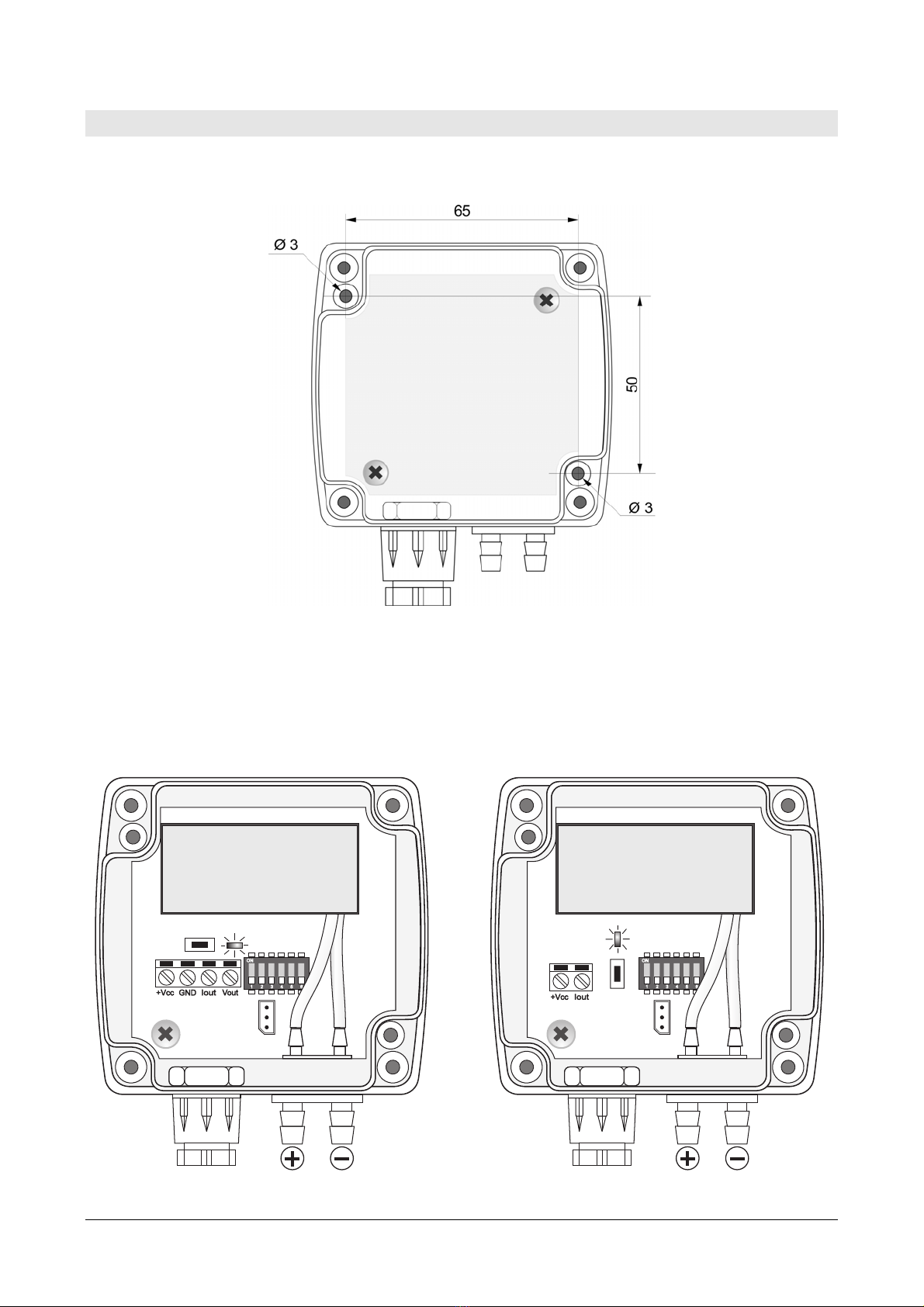

Available outputs, depending on the model:

•RS485 Modbus–RTU digital output HD402ST…);

•0...10 V voltage analog output HD402T…);

•0...20 mA / 4...20 mA active current analog output HD402T…);

•2-wire current loop) 4...20 mA analog output HD402AT…);

•ON/OFF relay switch HD402TR…L).

Different units of measurement can be chosen for each model and, in the models with

analog output, it is possible to choose the full scale f.s.) value for the output high,

intermediate or low range) and set the unipolar 0...+f.s.) or bipolar -f.s....+f.s.)

measuring range.

Versions with optional 4-digit LCD display option L) are available, which allow the

measured parameters to be displayed. The pressure relay switches always include the

display.

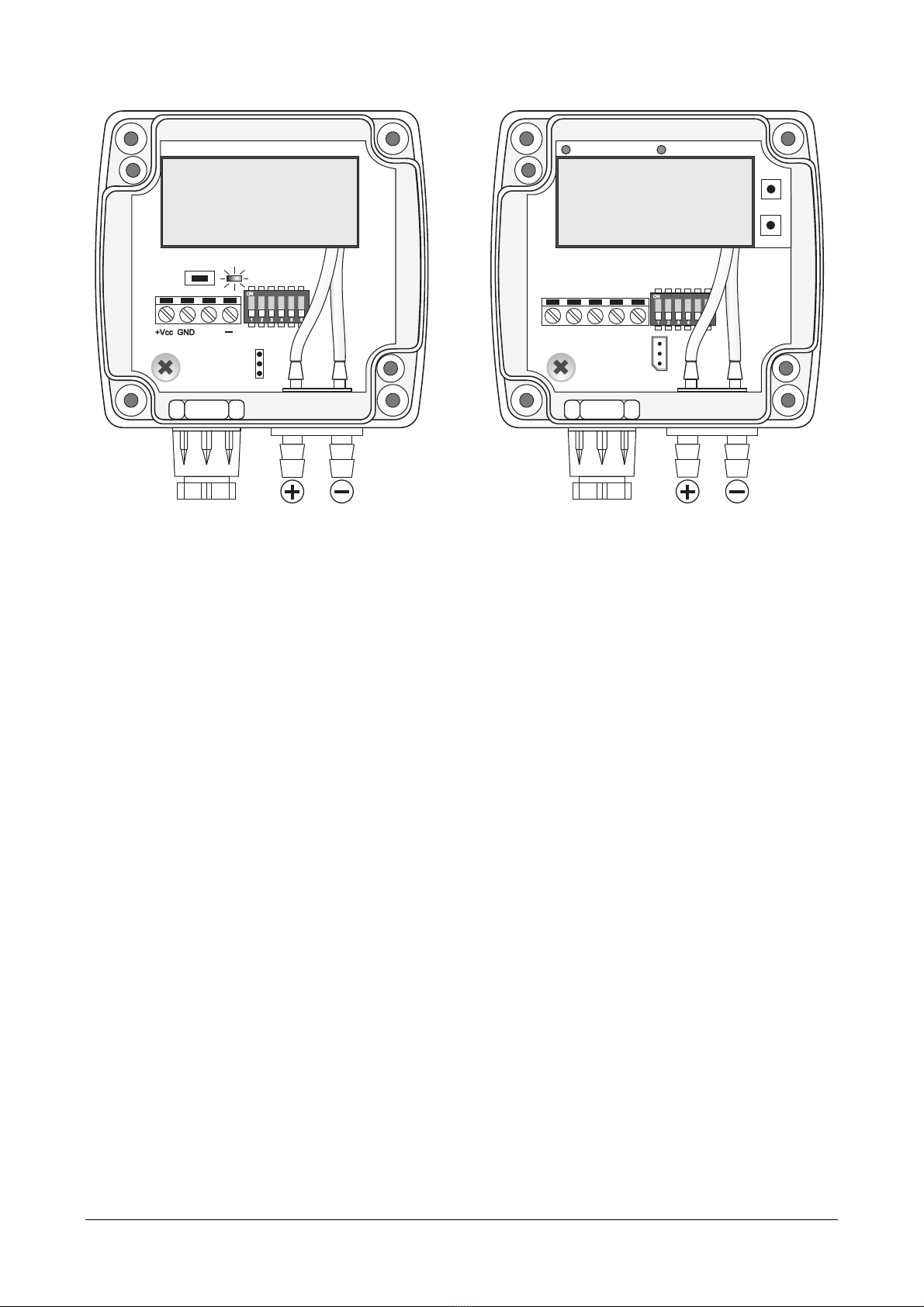

The configuration can be made by connecting the serial port of the instrument to the

PC or by means of the quick configuration dip switches on the circuit board. The ver-

sions with relay switch output are equipped with two internal buttons for the configura-

tion via display.

The instruments are factory calibrated and ready for use.

Models

HD402

“” = without LCD except HD402TR…)

L = with LCD

1 = range ± 250 Pa / 25 mmH2O / 1 inchH2O / 2,5 mbar

2 = range ± 1000 Pa / 100 mmH2O / 4 inchH2O / 10 mbar

3 = range ± 10 kPa / 50 mmHg / 1,5 PSI / 100 mbar

4 = range ± 100 kPa / 500 mmHg / 15 PSI / 1000 mbar

5 = range ± 200 kPa / 1000 mmHg / 30 PSI / 2000 mbar

T = 0…10 V and 0/4…20 mA active analog output

AT = 2-wire 4…20 mA analog output

ST = RS485 Modbus-RTU digital output

TR = ON/OFF relay switch output