English

English

1

This is a Reprocessing Manual for our total surgical system Primado2.

We recommend that prior to use, you carefully read this document to follow the correct reprocessing procedure so that you can continue

using the Attachments in the future.

In addition, keep this Manual in a place where a user can refer to it at any given time.

●The reprocessing instructions shown in this Manual are created based on the requirements of ISO 17664.

●NSK has verified the effectiveness of reprocessing with the procedure written in this Manual.

●In this Manual Bur, Drill, Blade and Rasp are collectively called Cutting Accessory(ies).

●For Precautions for Handling and Operation, Product Description, Operation, Maintenance, Troubleshooting and After-sales Service, refer to

each Operation Manual (see Table-1).

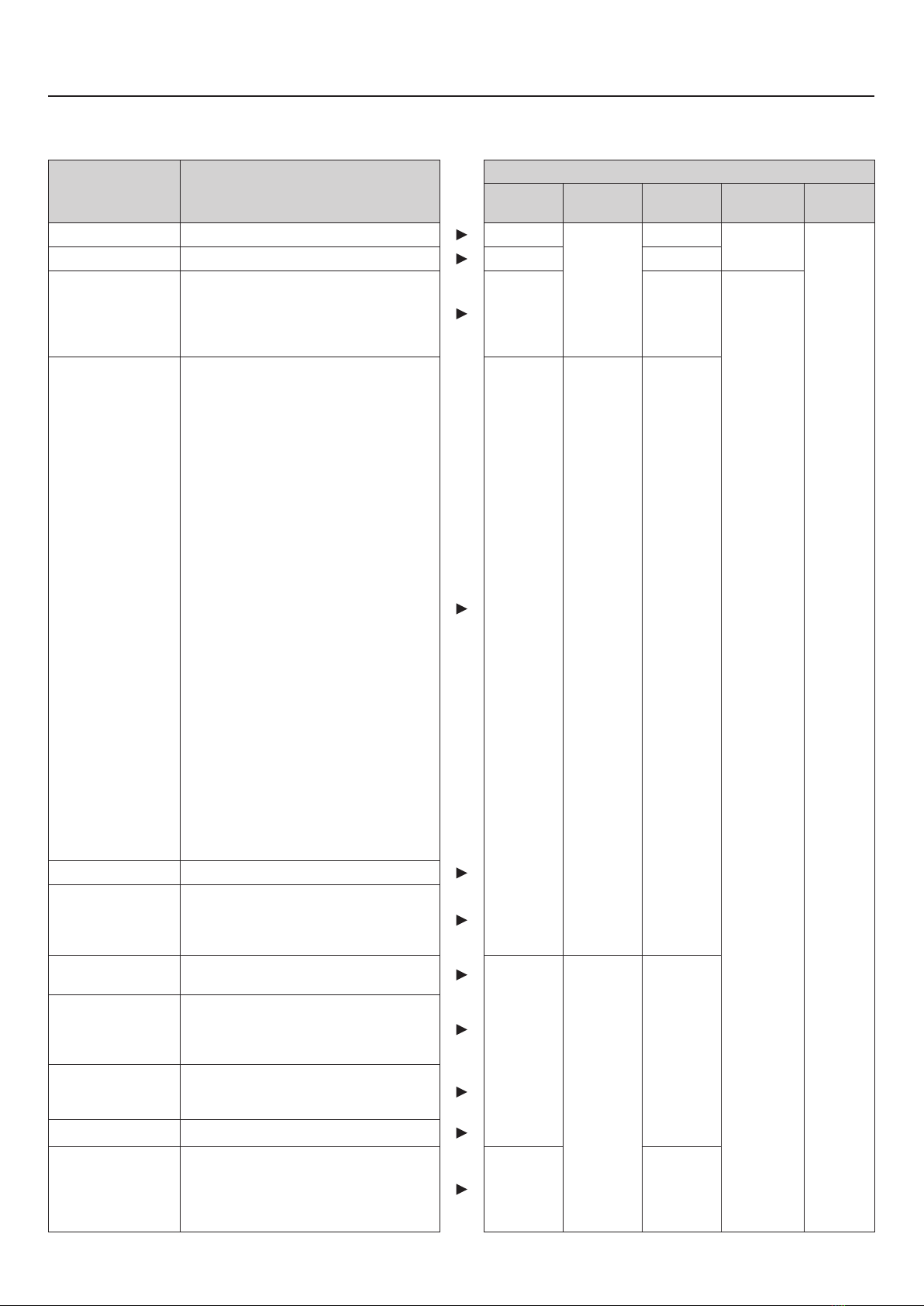

Table-1

Operation Manual Title Operation Manual No.

Primado2 OPERATION MANUAL Control Unit and Foot Controls OM-SE0021E

Primado2 OPERATION MANUAL Motors OM-SE0023E

Primado2 OPERATION MANUAL Attachments OM-SH0913MA

Cleaning Tool for Primado2 Attachment OM-SZ0904MA

Contents

1. Precautions for Handling and Operation ............................ 2

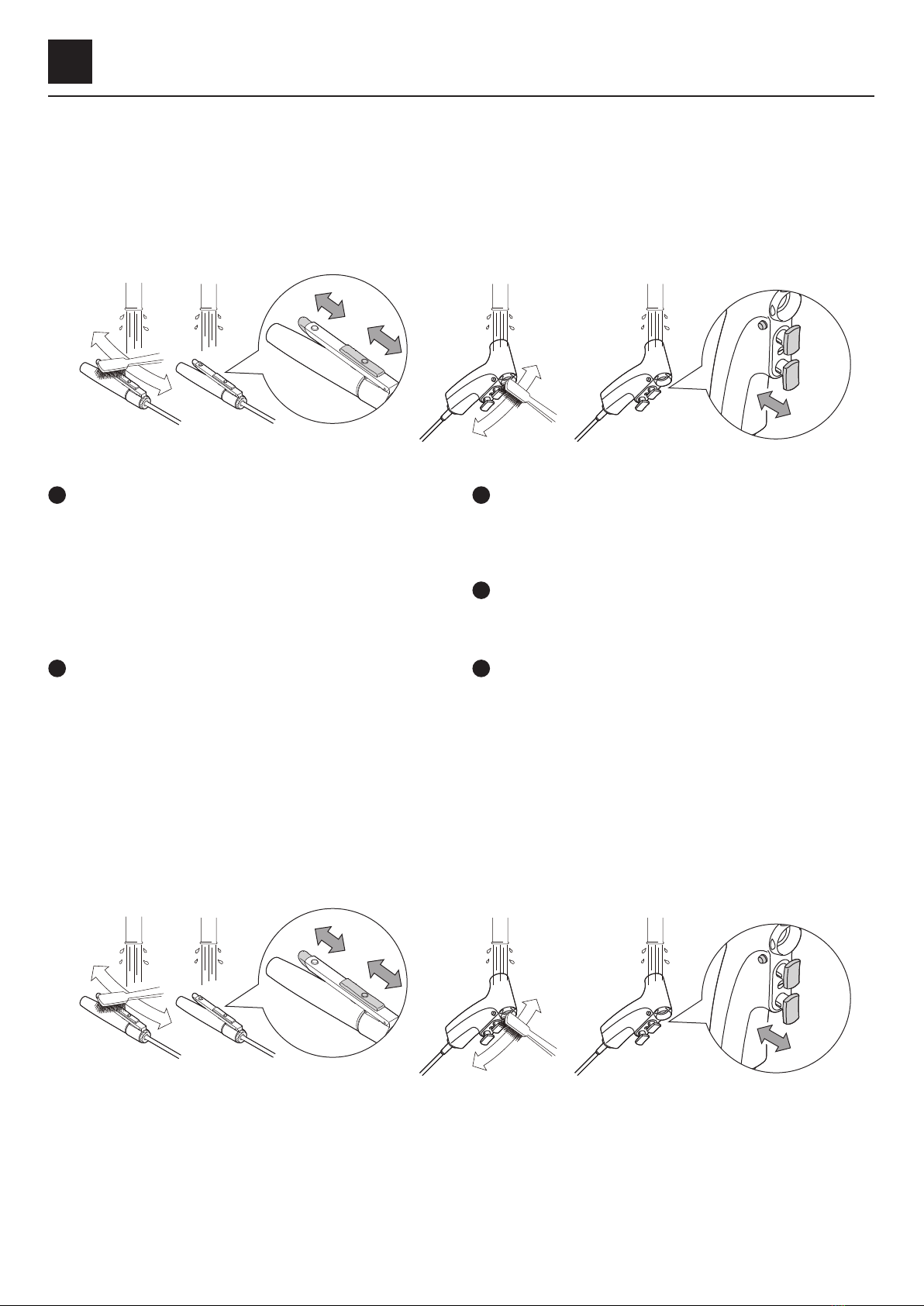

2. Moving Parts of Each Product ........................................... 3

3. Preparation ..................................................................... 5

3–1 Treatment at the Operating Site ...................................... 5

3–2 Reprocessing of Each Product ........................................ 6

4. Cleaning / Checking the Control Unit ................................ 7

4–1 Wipe Disinfecting .......................................................... 7

4–2 Checking ...................................................................... 7

5. Cleaning / Checking the Foot Control ................................ 7

5–1 Cleaning/Wipe Disinfecting ............................................. 7

5–2 Checking ...................................................................... 7

6. Cleaning / Checking the Motor ......................................... 8

6–1 Cleaning ....................................................................... 8

6–2 Checking ...................................................................... 9

7. Cleaning / Lubrication / Checking of the Attachment, Slim

Attachment Hub and Slim Tube ....................................... 10

7–1 Cleaning ..................................................................... 10

7–2 Lubrication ................................................................. 18

7–3 Checking .................................................................... 19

8. Cleaning / Checking the Hood, Beak, Duraguard,

Rotatable Duraguard, Wrench and Adaptor ...................... 20

8–1 Cleaning ..................................................................... 20

8–2 Checking .................................................................... 22

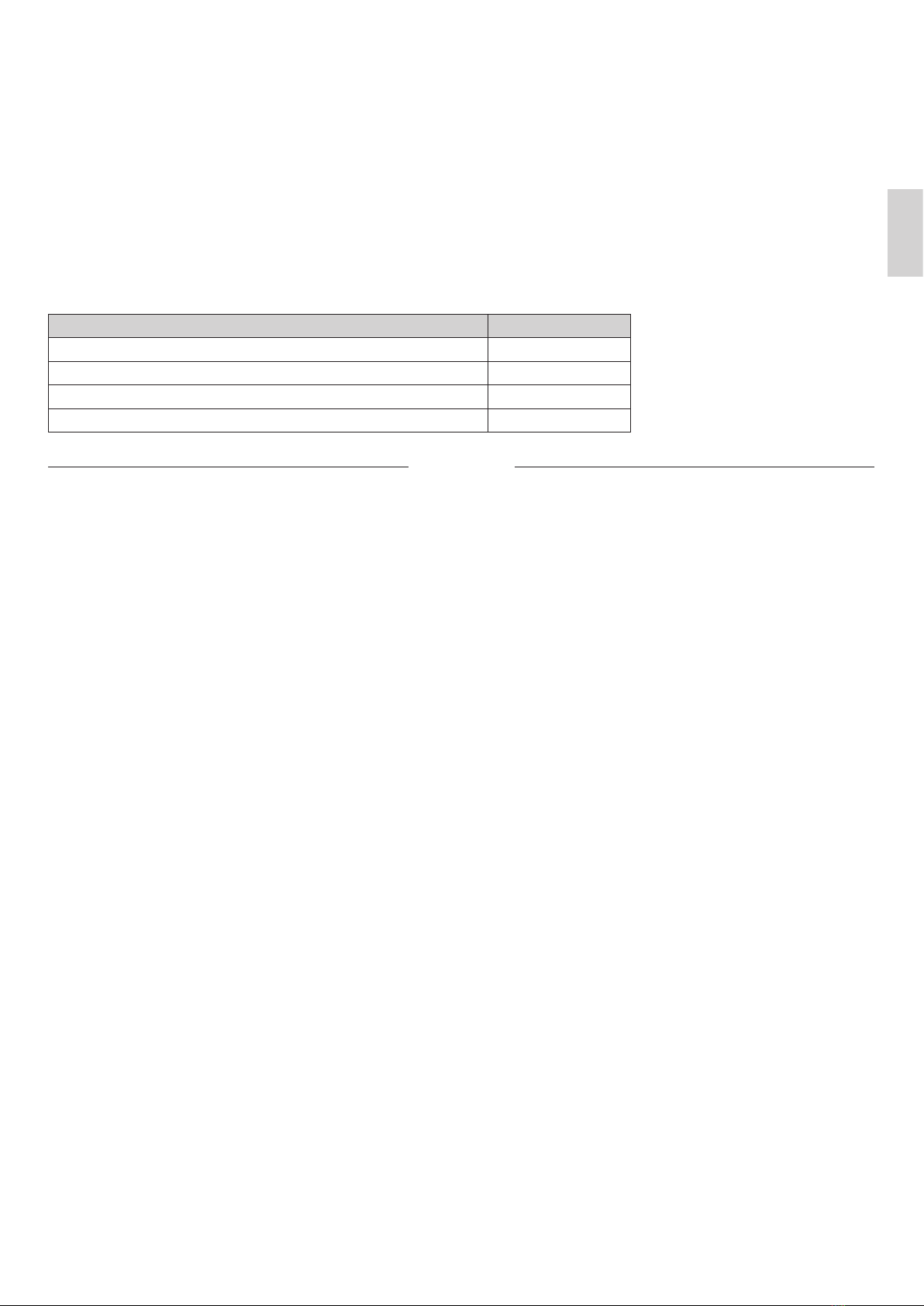

9. Cleaning / Checking the Irrigation Nozzle ........................ 23

9–1 Cleaning ..................................................................... 23

9–2 Checking .................................................................... 28

10. Packaging / Sterilization ................................................ 29

10–1 Packaging .................................................................. 29

10–2 Sterilization ................................................................. 29

11. Storage ......................................................................... 30

11–1 Storage ...................................................................... 30

11–2 Carrying to the Operating Site ....................................... 30

12. Disposing of Product ...................................................... 30

13. Symbols ........................................................................ 30