TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................3

Summary of safety precautions ................................................................................................................................3

Introduction ...............................................................................................................................................................4

Product description .................................................................................................................................................4

Indications for use...................................................................................................................................................4

Expected service life ...............................................................................................................................................4

Disposal/recycle .....................................................................................................................................................4

Contraindications....................................................................................................................................................5

Specifications .........................................................................................................................................................5

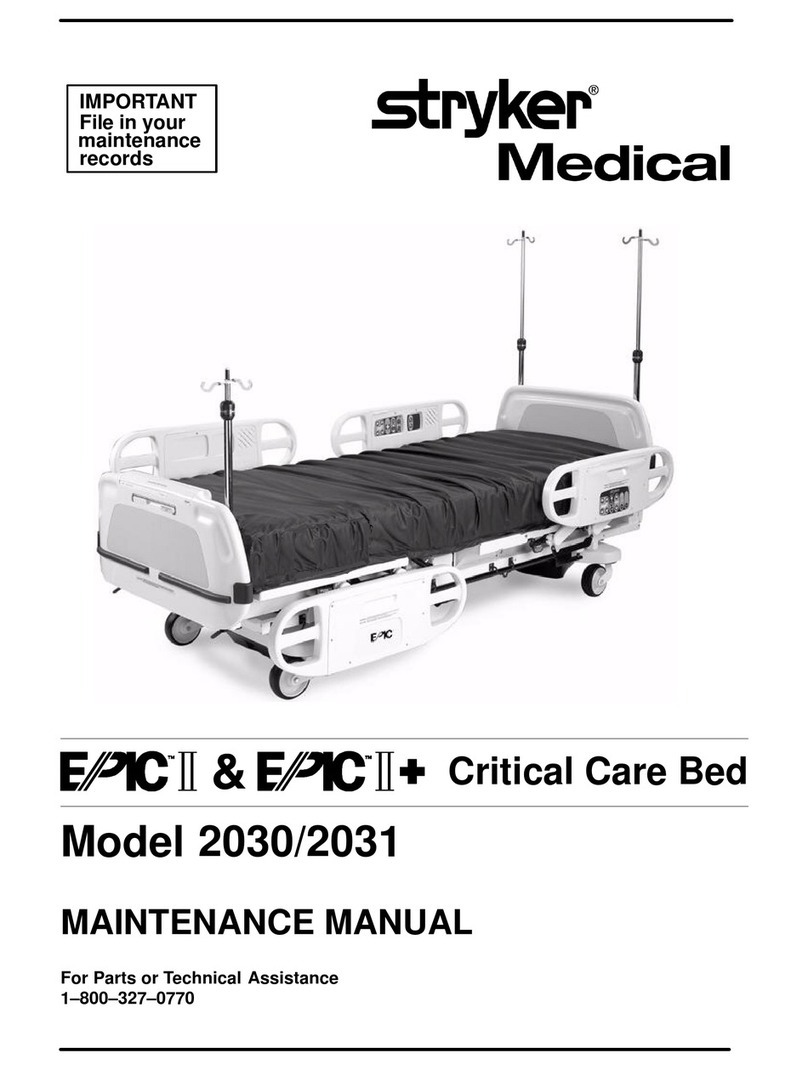

Product illustration ..................................................................................................................................................6

Contact information.................................................................................................................................................6

Serial number location.............................................................................................................................................7

Date of manufacture................................................................................................................................................7

Preventive maintenance ...........................................................................................................................................8

Service ......................................................................................................................................................................9

Caster maintenance ................................................................................................................................................9

Brake cam replacement...........................................................................................................................................9

Brake ring replacement .........................................................................................................................................10

Brake/steer pedal replacement ..............................................................................................................................11

Brake adjustment..................................................................................................................................................11

Jack replacement..................................................................................................................................................12

Siderail latch adjustment........................................................................................................................................14

Remove excess air from the hydraulic system .........................................................................................................15

Pneumatic Fowler adjustment................................................................................................................................15

Prime the pump ....................................................................................................................................................15

Check hydraulic fluid level .....................................................................................................................................16

Base lubrication ....................................................................................................................................................16

Troubleshooting....................................................................................................................................................17

“C” base assembly..................................................................................................................................................18

Jack/control assembly ............................................................................................................................................26

Jack base assembly ...............................................................................................................................................27

Caster wheel assembly...........................................................................................................................................28

Steer caster wheel assembly..................................................................................................................................29

5.75 in. molded wheel assembly ............................................................................................................................30

Brake adjuster assembly ........................................................................................................................................31

Litter assembly........................................................................................................................................................32

Litter assembly, high height option .........................................................................................................................36

Pneumatic Fowler assembly...................................................................................................................................38

Outer housing assembly, right - 1210-031-106 ......................................................................................................39

Outer housing assembly, left - 1210-031-107 ........................................................................................................40

Siderail assembly to litter........................................................................................................................................41

Siderail assembly....................................................................................................................................................43

Accessory rail to litter assembly .............................................................................................................................44

Footboard/chart holder ...........................................................................................................................................46

IV pole, removable - 0390-025-000 ........................................................................................................................47

IV pole assembly, permanent .................................................................................................................................48

Two-stage IV pole assembly - 1211-210-010.........................................................................................................49

IV pole latch - 1211-210-026 ..................................................................................................................................50

Footboard/chart holder - 0785-045-500 .................................................................................................................51

1080-009-002 Rev A.0 1 EN