Table of contents G 1700 series

2 / 20 B-H86.0.0X.DK2-3.1

Table of contents

1 About this documentation......................................................4

1.1 Foreword........................................................................................4

1.2 Legal notices..................................................................................4

1.3 Further information.........................................................................4

2 Safety.......................................................................................5

2.1 Explanation of safety symbols ........................................................5

2.2 Foreseeable misuse .......................................................................5

2.3 Safety instructions..........................................................................6

2.4 Intended use...................................................................................7

2.5 Qualified personnel.........................................................................7

2.6 Variants..........................................................................................7

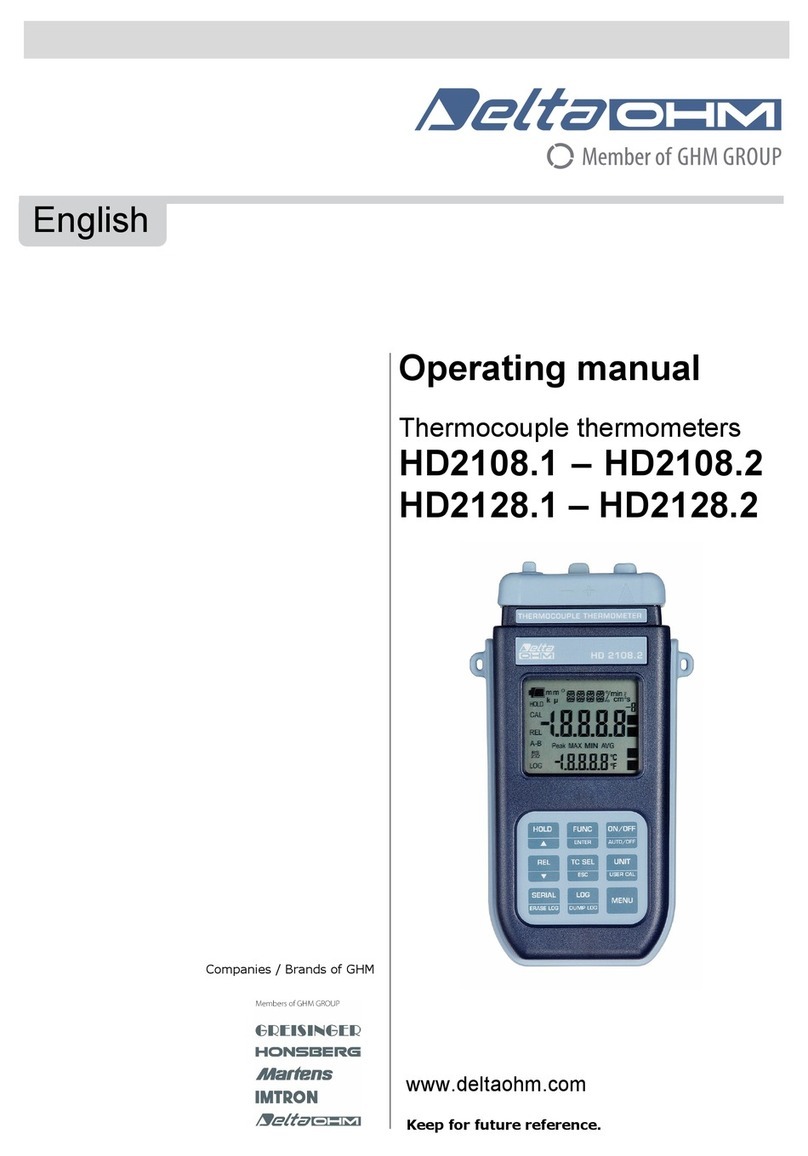

3 The device at a glance............................................................8

3.1 Display elements............................................................................8

3.2 Connections ...................................................................................8

3.3 Operating elements........................................................................9

4 Operation...............................................................................10

4.1 Opening the configuration menu...................................................10

4.2 Adjustment of the measuring input................................................12

5 Measurement Basics.............................................................13

5.1 Sensor/device accuracy................................................................13

5.2 Possible measuring errors............................................................13

5.2.1 Immersion depth...........................................................................13

5.2.2 Surface effects and poor heat transfer..........................................13

5.2.3 Cooling / evaporation....................................................................13

5.2.4 Response time .............................................................................13

6 Operation and maintenance.................................................14

6.1 Operating and maintenance notices..............................................14