H86.0.04.6C-01 Operating Manual Gourmet Thermometer Page 2 von 14

_____________________________________________________ _____________________________________________________________________________

Index

1SAFETY................................................................................................................................3

1.1 GENERAL NOTE .................................................................................................................3

1.2 INTENDED USE ..................................................................................................................3

1.3 QUALIFIED STAFF ..............................................................................................................4

1.4 SAFETY SIGNS AND SYMBOLS ............................................................................................4

1.1 REASONABLY FORESEEABLE MISUSE.................................................................................4

1.2 SAFETY GUIDELINES..........................................................................................................4

2PRODUCT DESCRIPTION...............................................................................................5

2.1 SCOPE OF DELIVERY ..........................................................................................................5

2.2 OPERATING AND MAINTENANCE.......................................................................................5

3OPERATION.......................................................................................................................6

3.1 DISPLAY ELEMENTS..........................................................................................................6

3.2 PUSHBUTTONS...................................................................................................................6

3.3 CONNECTIONS...................................................................................................................7

4START OPERATION.........................................................................................................7

5BASICS OF THE MEASUREMENT................................................................................7

5.1 POSSIBLE ERRORS..............................................................................................................7

5.1.1 Immersion depth.........................................................................................................7

5.1.2 Surface effects and bad heat transfer.........................................................................7

5.1.3 Cooling (evaporation)................................................................................................7

5.1.4 Response time.............................................................................................................7

6TEMPERATURE PROBE .................................................................................................8

6.1 PROBE ACCURACY/DEVICE ACCURACY..............................................................................8

6.1.1 Extra dünner Einstechfühler ......................................................................................8

6.1.2 Robuster Einstechfühler.............................................................................................8

7CONFIGURATION.............................................................................................................9

8ADJUSTMENT OF TEMPERATURE INPUT .............................................................10

9ACCURACY CHECK / ADJUSTMENT SERVICE.....................................................11

10 REPLACING BATTERIES...........................................................................................11

10.1 REQUIRED TOOLS:1X PHILLIPS SCREWDRIVER PH 1 ....................................................11

11 FAULT AND SYSTEM MESSAGES...........................................................................12

12 RESHIPMENT AND DISPOSAL.................................................................................12

12.1 RESHIPMENT.................................................................................................................12

12.2 DISPOSAL .....................................................................................................................12

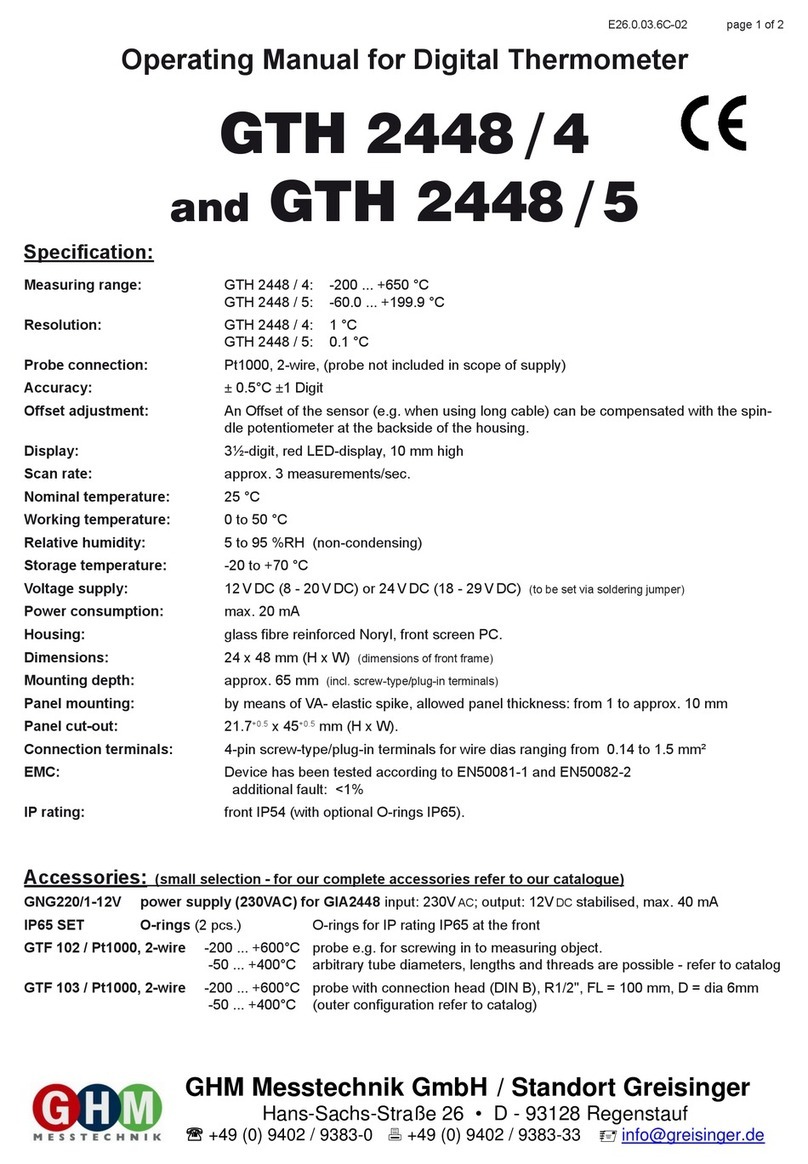

13 SPECIFICATION...........................................................................................................13

13.1 DEVICE.........................................................................................................................13

13.2 PROBE ..........................................................................................................................14