HD2101 - 2 - V2.3

CONTENTS

INTRODUCTION..................................................................................................................................................... 3

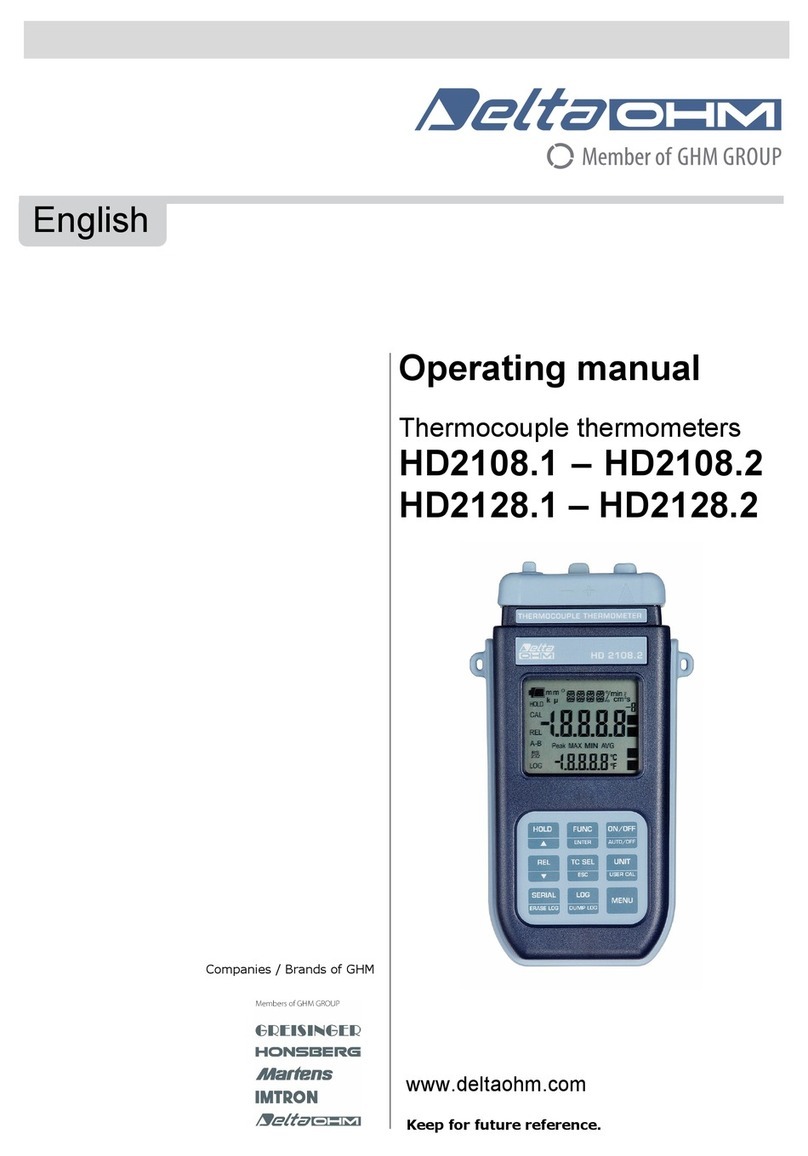

KEYBOARD AND MENU DESCRIPTION ............................................................................................................ 8

THE PROBES..........................................................................................................................................................14

MEASUREMENT OF RELATIVE HUMIDITY..................................................................................................................14

Calibration of the combined humidity/temperature probe ...................................................................................14

Humidity and Comfort indices...........................................................................................................................16

DIRECT INPUT INTO Pt100, Pt1000 AND Ni1000 TEMPERATURE PROBES ...................................................................18

How to measure ................................................................................................................................................18

Instructions to connect the TP47 connector for 4 wire Pt100, Pt1000 and Ni1000 probes....................................18

Direct connection of 4 wire Pt100 sensors .........................................................................................................20

WARNINGS AND OPERATING INSTRUCTIONS ..............................................................................................21

INSTRUMENT SIGNALS AND FAULTS..............................................................................................................22

LOW BATTERY WARNING AND BATTERY REPLACEMENT.......................................................................24

INSTRUMENT STORAGE.....................................................................................................................................25

SERIAL INTERFACE AND USB ...........................................................................................................................26

STORING AND TRANSFERRING DATA TO A PERSONAL COMPUTER......................................................28

THE LOGGING FUNCTION -ONLY FOR HD2101.2......................................................................................................28

CLEARING THE MEMORY -ONLY FOR HD2101.2 ......................................................................................................28

THE PRINT FUNCTION ...........................................................................................................................................29

CONNECTION TO A PC........................................................................................................................................30

CONNECTION TO THE RS232C SERIAL PORT OF THE INSTRUMENT .............................................................................30

CONNECTION TO THE USB 2.0 PORT OF THE INSTRUMENT -ONLY FOR HD2101.2......................................................30

NOTES ABOUT WORKING AND OPERATING SAFETY .................................................................................31

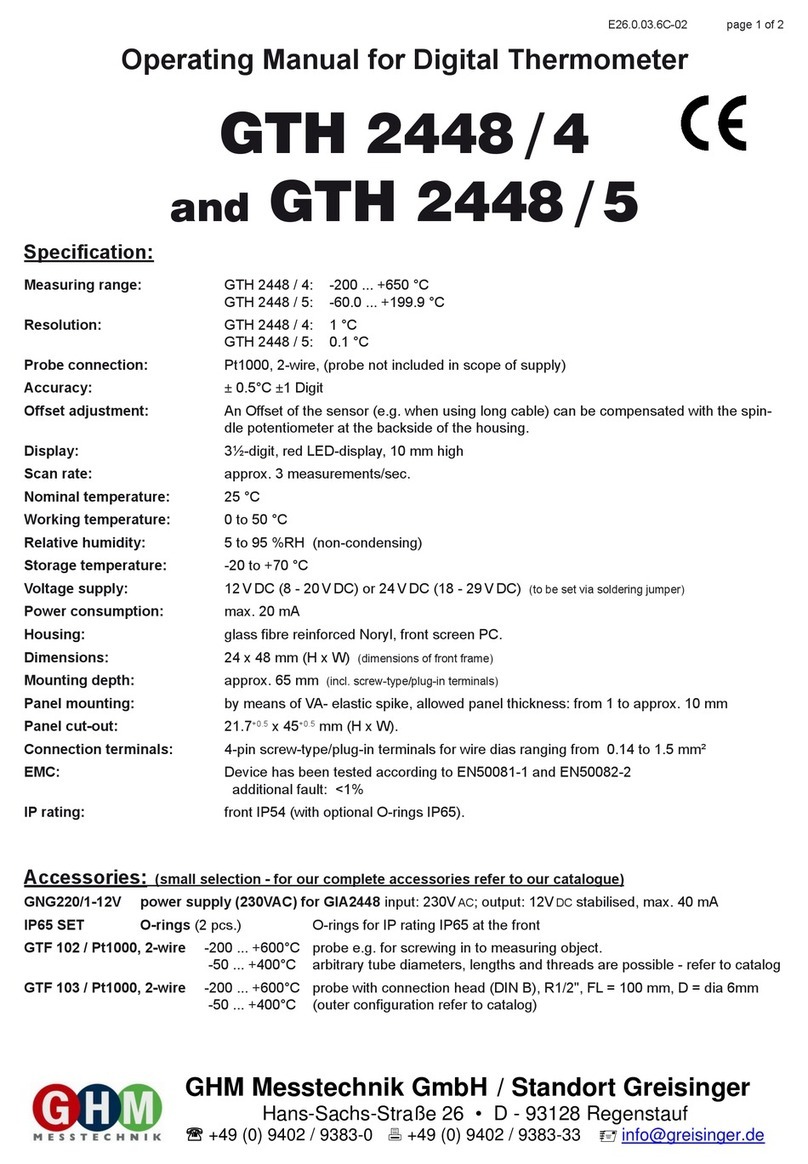

INSTRUMENT TECHNICAL CHARACTERISTICS..........................................................................................32

TECHNICAL DATA OF PROBES AND MODULES IN LINE WITH THE INSTRUMENT ............................................................34

TEMPERATURE PROBES Pt100 SENSOR USING SICRAM MODULE.................................................................................34

RELATIVE HUMIDITY AND TEMPERATURE PROBES USING SICRAM MODULE................................................................35

PROBES Pt100 4WIRES AND Pt1000 2WIRES............................................................................................................35

ORDER CODES ......................................................................................................................................................36