1

NEVER LEAVE THE HEATER

UNATTENDED WHILE BURNING!

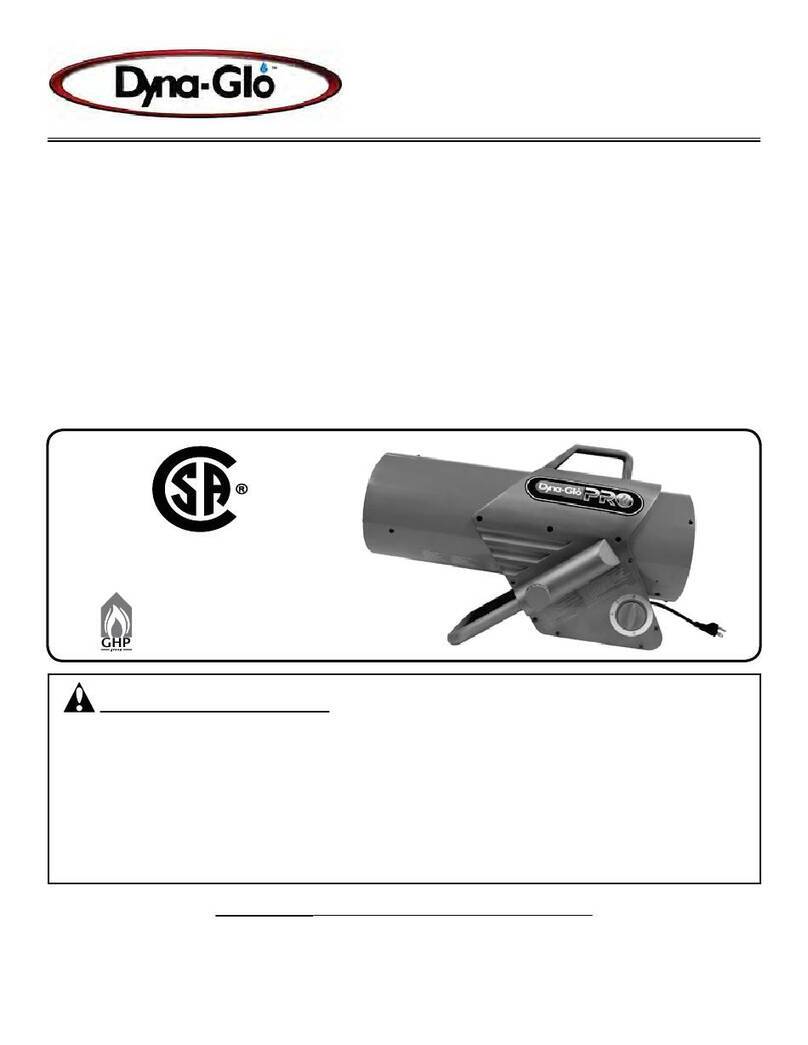

DANGER:IMPROPER USEOF THIS HEATER CAN RESULT IN SERIOUS INJURY OR DEATH

FROM BURNS, FIRE, EXPLOSION, ELECTRICALSHOCK AND/OR CARBON

MONOXIDEPOISONING.

WARNINGS:

1. RISK OF INDOOR AIR POLLUTION!

•Usethis heater only in well ventilated areas. Provide at least a three-square foot(2,800 sq. cm.)

opening of fresh outside air for each 100,000 BTU/hr. of heater rating.

•People with breathing problems should consult a physician beforeusing the heater.

•Carbon monoxide poisoning: Early signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness

and/or nausea. If you have these signs, the heater may notbeworking properly.

Get fresh air at once!Have the heater serviced. Some people are more affected by carbon monoxide than others.

These includepregnant women, persons with heart or lung disease or anemia, thoseunder the influence of alcohol, or

those at high altitudes.

•Never use this heater in living or sleeping areas.

2. RISK OFBURNS/FIRE/EXPLOSION!

•NEVER use any fuel other than1-K kerosene, #1 disel/fuel oil inthis heater.

•NEVER use fuel suchasgasoline, benzene, paint thinners or otheroil compounds in this heater.

(RISK OF FIRE OR EXPLOSION)

•NEVER use thisheater where flammable vapors may be present.

•NEVER refill the heaters fuel tank while heater is operating or is still hot.

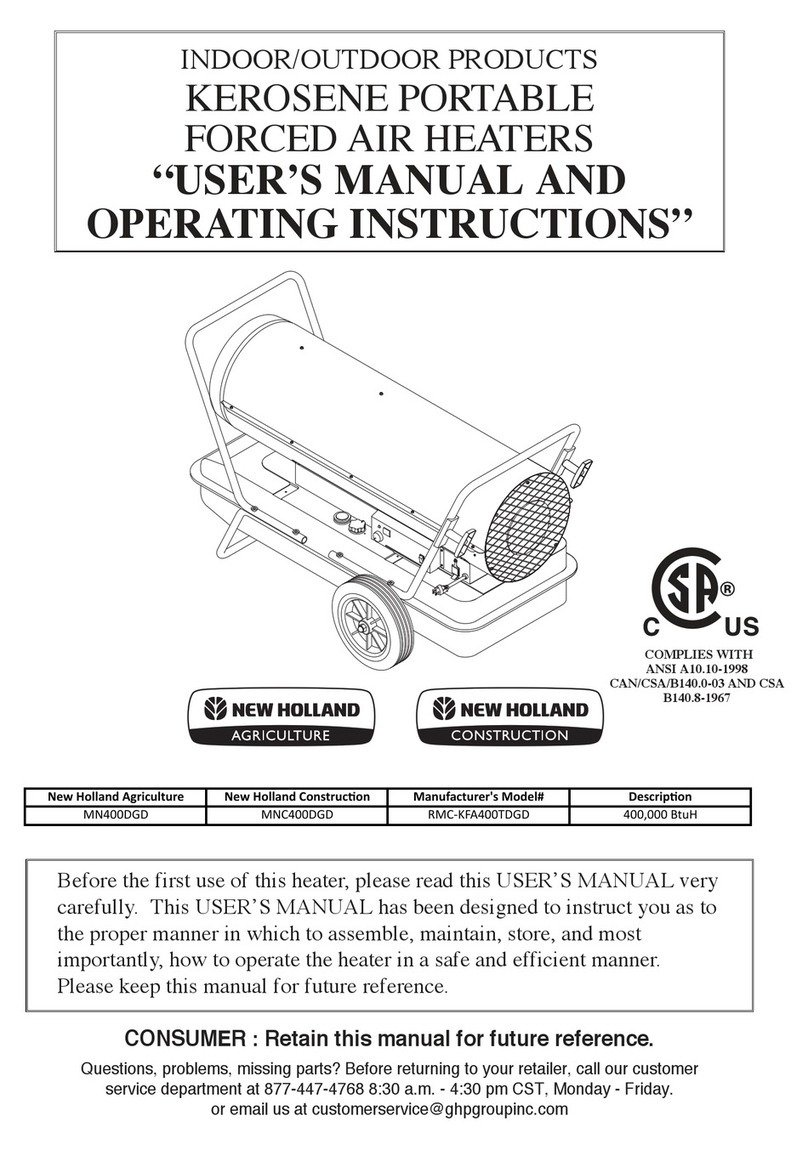

Minimum Clearances: Outlet: 8 feet (250cm) /Sides, top and rear: 4 feet (125cm)

•NEVER block airinlet (rear) or air outlet (front) of heater.

•NEVER use duct work in front orbehind of heater.

•NEVER move, handle, service a hot, operating or plugged in heater.

•NEVER transport heater with fuel init’s tank.

•When used withanoptional thermostat or if equipped with a thermostat heater may start at any time.

•ALWAYSlocate heaterona stable and level surface.

•ALWAYSkeep children andanimalsaway from heater.

•Bulk fuel storage should be a minimum of 25 ft. from heaters, torches, portable generators or other sources of ignition.

All fuel storage should be in accordance with federal, state or local authorities having jurisdiction.

3. RISK OF ELECTRIC SHOCK!

•Use only the electrical power (voltage and frequency) specified on the model plate of the heater.

•Use only a three-prong, grounded outlet and extension cord.

•ALWAYSinstall the heater so that it is not directlyexposed to water spray, rain, dripping water or wind.

•ALWAYSunplug the heater when not in use.

PROPOSITION 65 WARNING: Fuels used in gas, wood-burning or oil fired appliances, and the

products of combustion of such fuels, contain chemicals known to the State of California to cause cancer,

birth defects and other reproductive harm.

MASSACHUSETTS RESIDENTS: Massachusetts state law prohibits the use of this heater in any

building which is used in whole or in part for human habitation. Use of this heating device in

Massachusetts requires local fire dept. permit (M.E.L.C. 148, Section 10A.)

CANADIAN RESIDENTS: Use of this heater shall be in accordance with authorities having

jurisdiction and CSA Standard B139.

NEW YORK CITY RESIDENTS: For use only at construction sites in accordance with applicable NYC

codes

under NYCFD certificate of approval # 5034 and 5037.

CAUTION :Hot while in operation. Do not touch. Keep children,

clothing and combustibles away from heater.