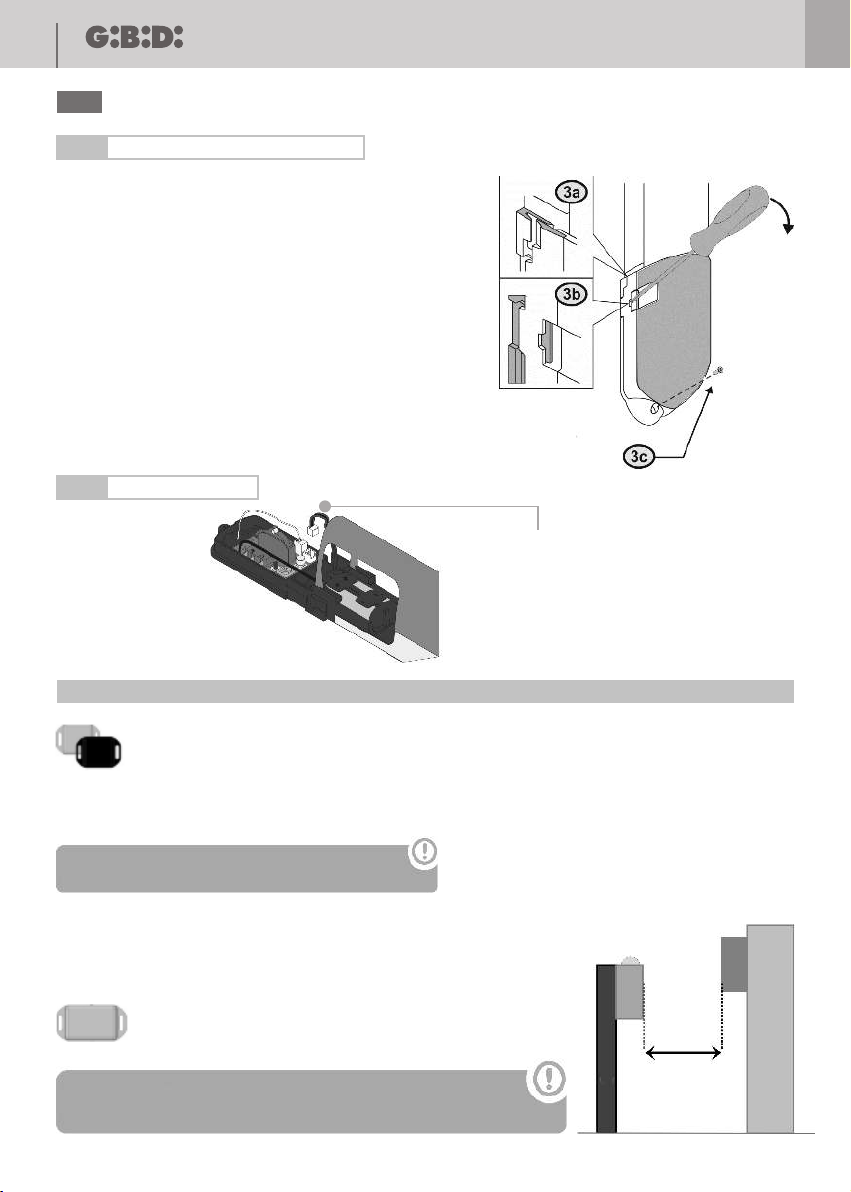

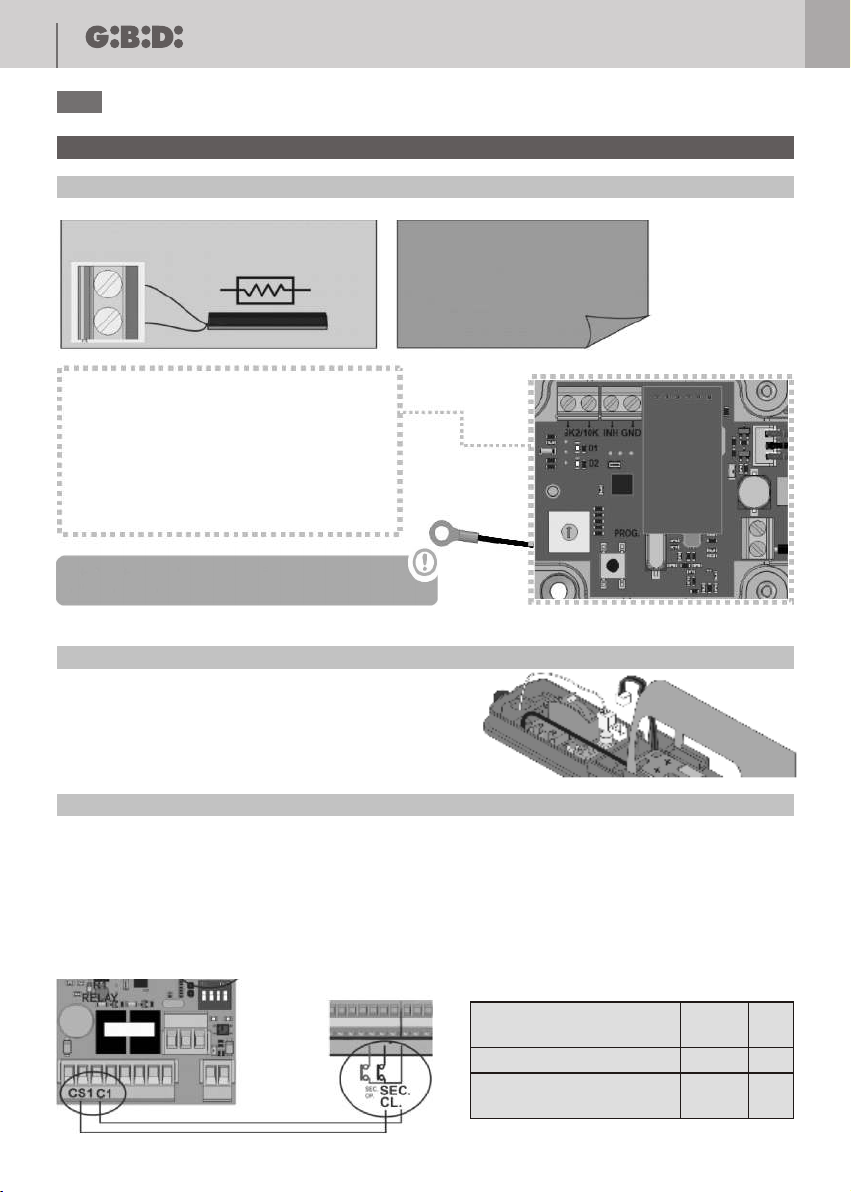

CLOSING GATE

Gate must be

TOTALLY OPEN

to fix the grey magnet.

CAP ACTIVE

CAP T

CAP

MAGIN

SUPPORT

INHIBITION ZONE: NO TOUCH

30-50 CM

8 9

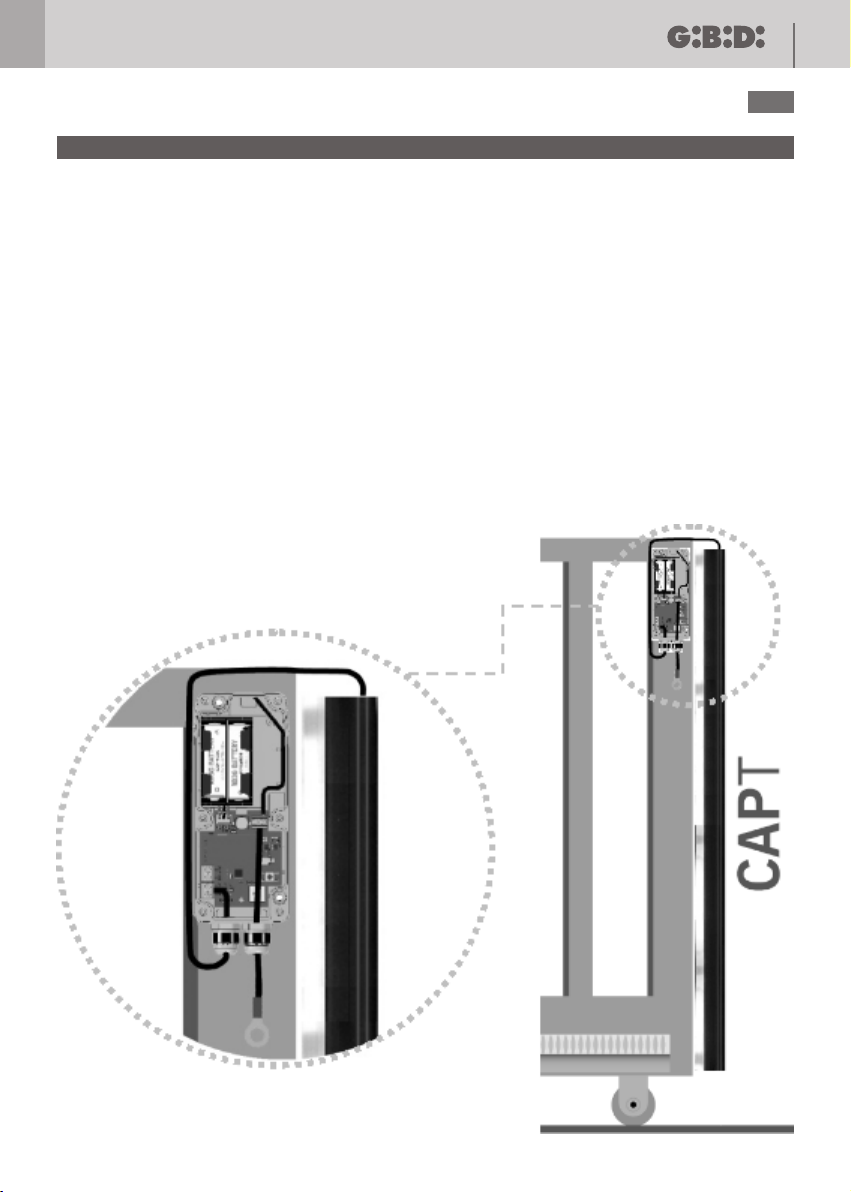

3.2.2 POSITIONING OF THE COVER

3.2.3 POWER SUPPLY

BATTERY CONNECTOR

Connect the batteries for operation.

Do not carry the equipment with

batteries connected.

3.3 - CAP MAGIN

SUPPORT

MAGIN

1-2 cm

MAGNET

GATE

MAGNETS: at the gate.

The Grey magnet should be installed to activate the NO-TOUCH sensor when the gate starts the closing movement.

The Black magnet switches off the NO-TOUCH sensor in order to allow the gate to close fully.

CAP MAGIN: install onto a support near the magnets and at the

same height

GREY – BLACK magnets position depends on the direction of the gate.

CAP MAGIN LED must be GREEN while gate is closing/opening, RED when

gate is totally closed/open.

Depending on the gate direction, BLACK magnet

is the one which de-activates the NO-TOUCH.

Before fixing the magnet, CAP ACTIVE/CAP T

must be programmed at the receiver.

The location of the black magnet indicates the

inhibition zone at closing.

In case the gate is not totally opened/closed, a safety time of 5

minutes is added to avoid battery consumption.

Maximum NO TOUCH activation time = 5 minutes

To insert the soft cap, place it in front of the support plate, taking

care to slide the flaps in their seats (3a) and the two lateral locking

hooks inside of slits arranged (3b).

Apply a light pressure so that there is a click to indicate the correct

placement of the same

Secure the cover with the screw provided.

To remove the cover reverse the procedure: remove the screw

(3c), release the cap by inserting a tool inside the slits pushing

the hooks inward.

3.3.1 FIXING THE ACTIVATION MAGNET

3.3.2 FIXING THE DEACTIVATION MAGNET

GREY

BLACK

With the GATE TOTALLY OPEN fix the south field magnet (Grey).

The Grey magnet must be 2-3 cm away from the MAGIN detector. When the gate starts closing, the Grey magnet

travels past the MAGIN and NO-TOUCH gate sensor is activated.

LED indicator on MAGIN detector changes to green color when Grey magnet passes in front of MAGIN.

With the GATE AT 30-50 cm FROM ITS CLOSED POSITION:

The Black magnet must be fixed at the other extreme of the gate (in respect of the grey magnet). The location of

this magnet depends on the inhibition zone desired.

Due to NO TOUCH detection, it is required that an INHIBITION ZONE is created at the end of the gate movement in

order to avoid the detection of the wall support by NO TOUCH detector. In this zone, the safety edge will only be

activated from normal mechanical compression.

Inhibition zone length depends on NO TOUCH sensitivity adjustment.

When NO-TOUCH sensor is detecting, an LED on the transmitter is activated. If the indicators on the transmitter

are switched off, it will be necessary to press the PROG button on the transmitter to activate, for 5 minutes,

the LED function.

The LED indicator on MAGIN detector changes to a red color when black magnet passes in front of the MAGIN.

CAPTIVE CAPTIVE

EN EN

Before fixing the black magnet, CAP ACTIVE/CAP T

must be programmed at the receiver.