10

Dry Heat

IEC 60068-2-2 Ed. 5.0 (2007-07)

Vibration

IEC 60068-2-6 Ed. 7.0 (2007-12) 5 g

Repetitive Shock

IEC 60068-2-27 Ed. 4.0 (2008-02), 40g, 6ms

Non-Repetitive Shock

IEC 60068-2-27 Ed. 4.0 (2008-02), 30g, 15ms

8.0 MEASUREMENT:

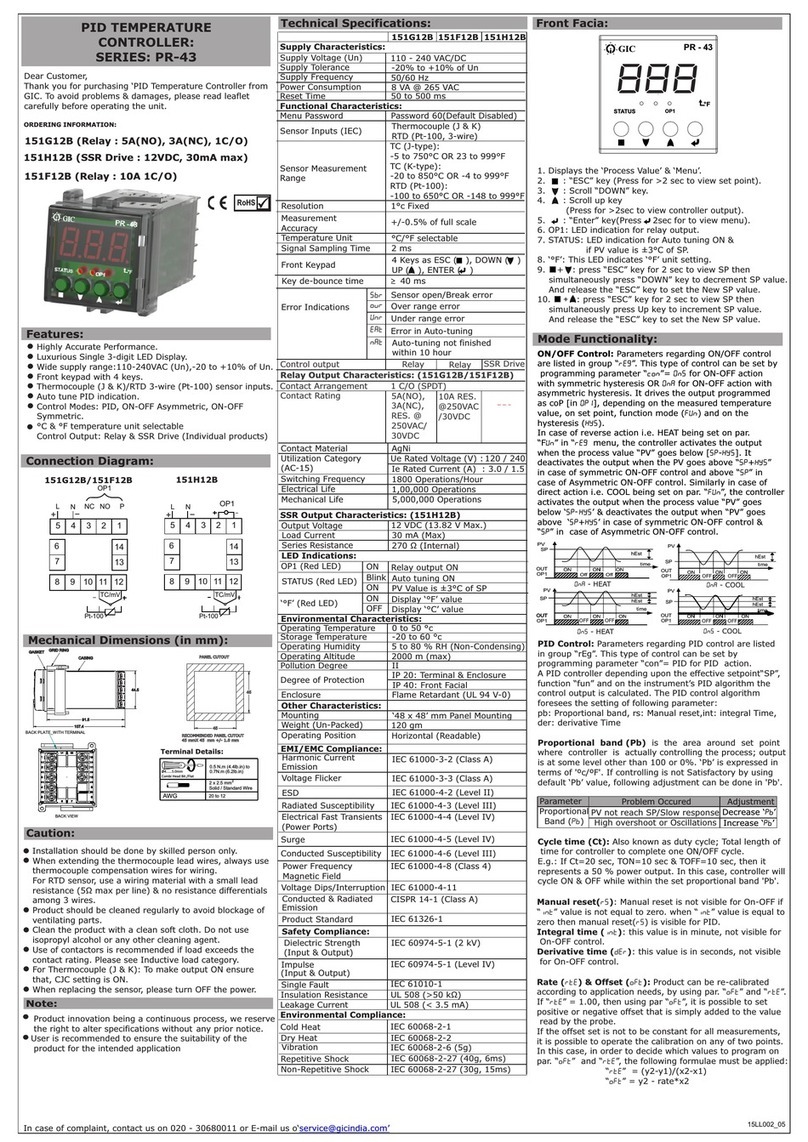

Parameters for this are included in the group “InP”. Inputs accepted are Thermocouples

(J, K, E, S, B, R) mv Signals (0-50) mV, (0-60) mV, (12-60) mV,RTD

Pt100.Recommendation is to switch OFF and ON the instrument when these parameters

are modified, to obtain a correct measurement. This can be through par. “unit”, the unit

of measurement (0C, 0F) and through parameter “dp” decimal point. In case of analog

input signals, the value that instrument must visualize at the start of scale is on par.

“IscL” and the value that instrument must visualize at the end of scale is on par.

(Parameter) “Isch”. Instrument can be re-calibrated according to application needs, by

using par. “oFst” and “rate”. If “rate” = 1.000, then using par “oFst”, it is possible to set

positive or negative offset that is simply added to the value read by the probe.

If the offset set is not to be constant for all the measurements, it is possible to operate

the calibration on any of two points. In this case, in order to decide which values to

program on par. “oFst” and “rate”, the following formulae must be applied:

“rate” = (y2-y1)/(x2-x1)

“oFSt” = y2 - rate*x2

Where, y1 = Measured temperature 1

x1 = temperature displayed by instrument

y2 = Measured temperature 2

x2 = temperature displayed by instrument

The instrument thus visualizes the temperature as:

y = x * “rate” + “oFst”

Where y = displayed value and x = measured value.

8.1 Output in case of measurement error:

In case of measurement error (over range/under range/sensor open), the instrument

supplies the power as programmed on par “oPP”. Incase of PID control, the power

output is as a percentage of cycle time. In case of ON/OFF control, the Cycle time is

automatically considered as 20 s (”e.g. In event of probe error with ON/OFF control and

“oPP = 50” the control output will be activated for 10s and deactivated for 10s till

measurement error remains.)

9.0 Display:

Using par. “dIsP”, located in the group “conF”, it is possible to configure the lower

display to visualize different parameters like the control power (coP), operating set point

(sP). In group “conF”, the par. “LEd” is used to definethe LED shift index functioning for

the three LED’s represented as: ’+’, ‘-’, ‘=’. The lighting up of the ‘=’ LED indicates

that the process value is within the range [sP-LEd] and [sP+LEd].

The lighting ‘-’ LED indicates that the process value is lower than [sP-LEd] and lighting

up of ‘+’ indicates that the process value is higher than [sP+LED]