Pagina – page – Seite 1

Indice / Table of contents / Inhaltsverzeichnis

Technical features ................................................................................................................................... 3

Symbology ............................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Identification plate of the instrument ....................................................................................................... 4

Notes ...................................................................................................................................................... 5

Mounting of the instrument ...................................................................................................................... 5

Rear panel ............................................................................................................................................... 5

Power supply of the instrument ............................................................................................................... 6

Connection of the load cell ...................................................................................................................... 6

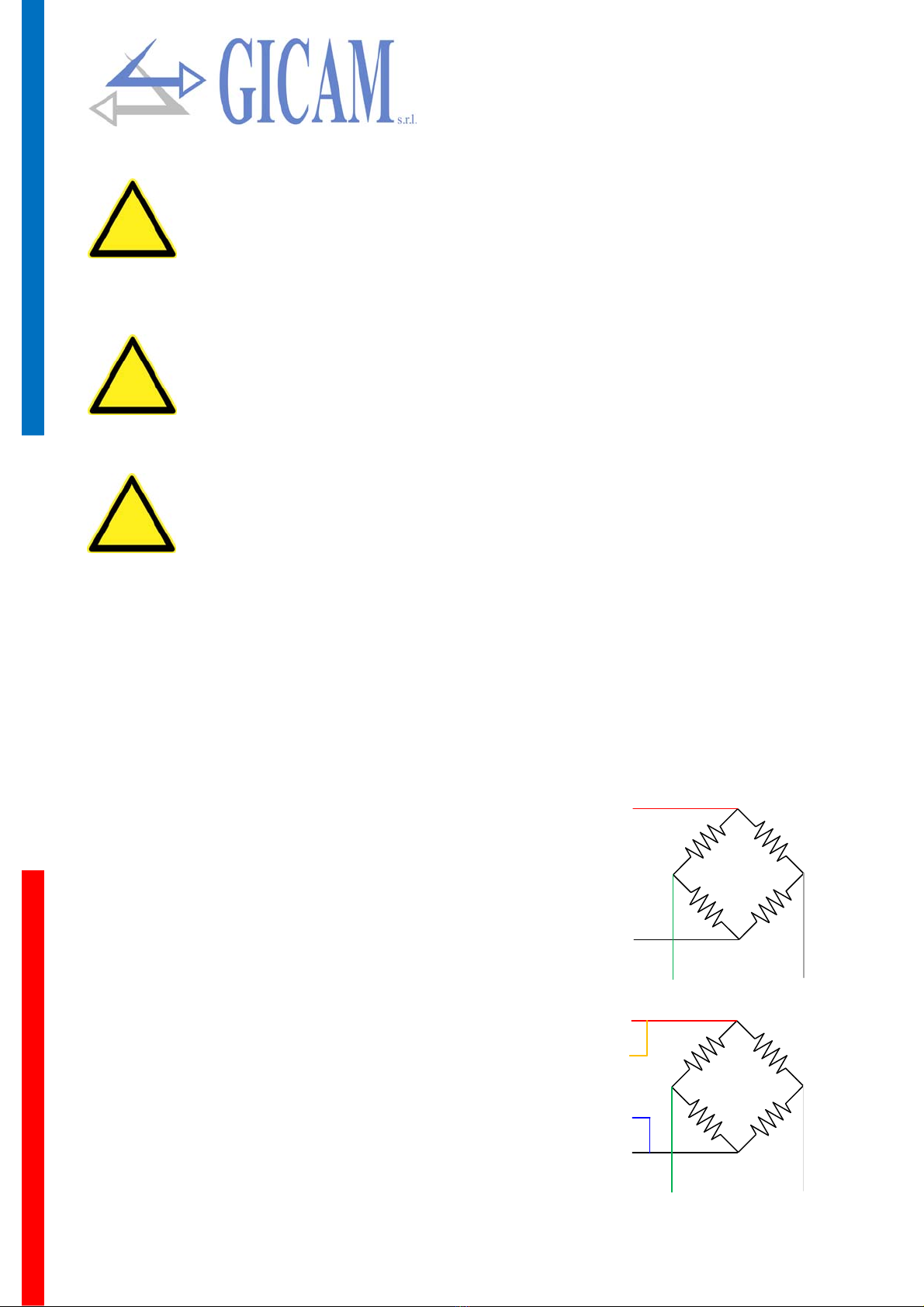

4-wire connection ............................................................................................................................... 6

6-wire connection ............................................................................................................................... 6

Logic input connection (lower 12-pole terminal block) ............................................................................ 7

Logic output connection (lower 12-pole terminal block) .......................................................................... 7

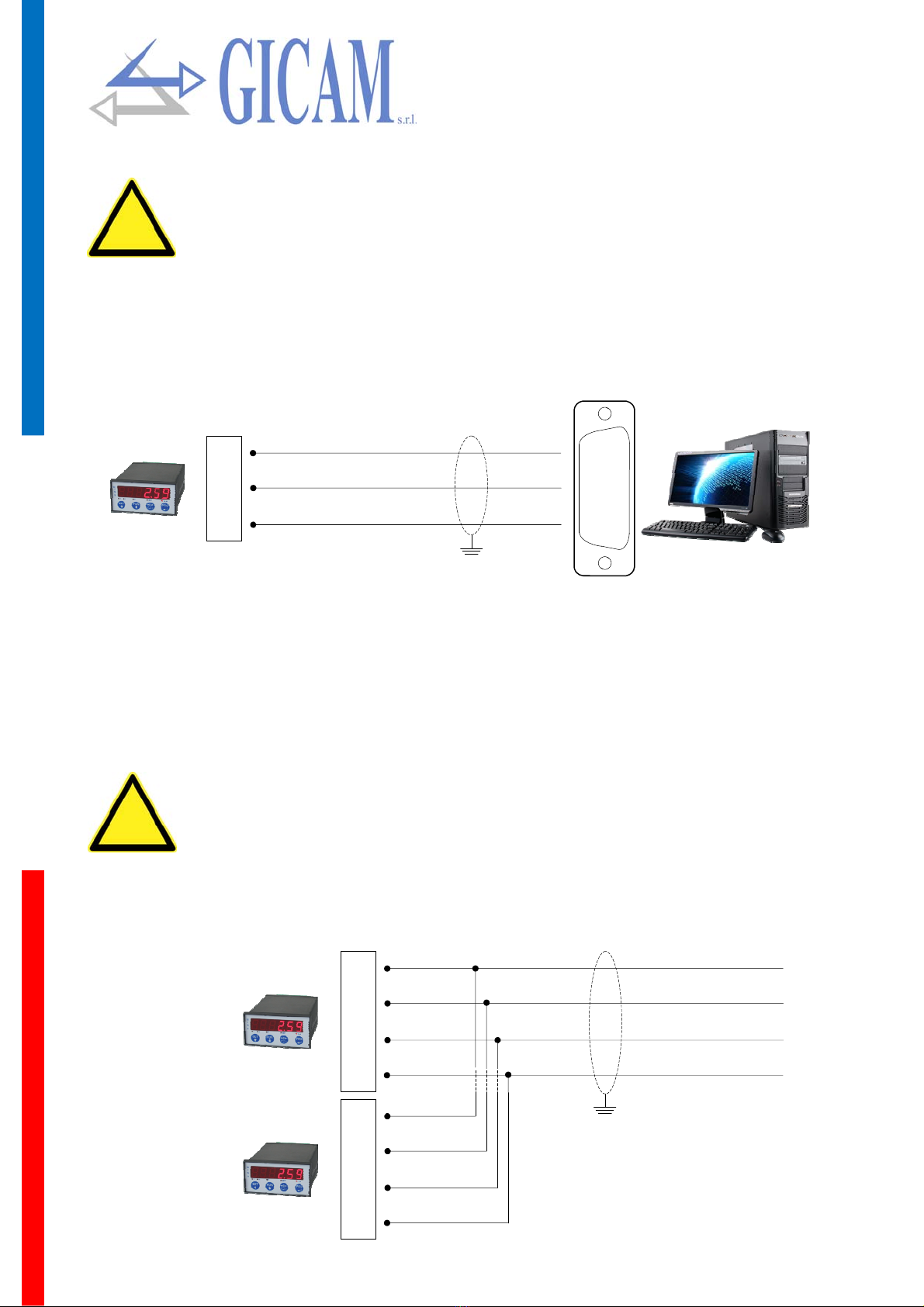

RS232 serial connection with PC (upper 12-pole terminal block) ........................................................... 8

Connection with RS422 serial line (upper 12-pole terminal block) ......................................................... 8

Connection with RS485 (upper 12-pole terminal block) .......................................................................... 9

Serial RS422 connection with repeater ................................................................................................... 9

RS422 connection with RIP60HA repeater ........................................................................................ 9

RS422 connection with RIP100HE repeater ...................................................................................... 9

Serial RS232 connection with printer .................................................................................................... 10

Serial RS232 connection with BCD card ............................................................................................... 10

Connection analog output (optional) ..................................................................................................... 11

PROFIBUS connection (optional).......................................................................................................... 11

Connection summary ............................................................................................................................ 12

Troubleshooting guide ........................................................................................................................... 12

Main operating characteristics ............................................................................................................... 13

The front panel of the instrument .......................................................................................................... 13

Display .............................................................................................................................................. 13

LED indicators .................................................................................................................................. 13

Display indications ................................................................................................................................. 14

Use of the keyboard .............................................................................................................................. 14

Keyboard lock / unlock functio ............................................................................................................... 14

Data setting ........................................................................................................................................... 15

Restore zero (semi-automatic zero) ...................................................................................................... 15

Input / output .......................................................................................................................................... 15

Dosing parameters programming .......................................................................................................... 16

Dosing operation on loading .................................................................................................................. 16

Dosing operation on discharge .............................................................................................................. 17

Dosing operation on loading without zeroing ........................................................................................ 17

Calibration data menu ........................................................................................................................... 18

Weight calibration and linearization....................................................................................................... 20

Linearization procedure .................................................................................................................... 20

Dosing program selection ...................................................................................................................... 21

Weighing parameters setting menu ...................................................................................................... 21

Logic inputs and outputs ....................................................................................................................... 23

Serial communication ports set-up ........................................................................................................ 24

Transmission frequency tables .............................................................................................................. 26

User manual .............................................................................................................................................. 13

Indice / Table of contents / Inhaltsverzeichnis ........................................................................................ 1

Installation manual ..................................................................................................................................... 3