- 9 -

11 LEAK TEST

This test may be performed at any time to check that the pipette does not leak,

especially after performing a maintenance or decontamination procedure. If a pi-

pette fails this test, replace the O-ring and seal. After making sure that the pipette

is correctly reassembled, repeat this test.

Symptom Possible Cause Action

Tips fall o or Low quality tips Use PIPETMAN DIAMOND tips

do not t correctly Tip-ejector damaged

Replace tip-ejector

Ejector spacer damaged Replace ejector spacer

Dirty tip-holder Clean them with ethanol or isopropanol

Damaged tip-holder Contact your local Gilson authorized service center

Pipette won’t aspirate Connecting nut is loose Tighten connecting nut

Pipette is inaccurate Connecting nut is loose Tighten connecting nut

Pipette is not precise

Connecting nut is loose Tighten connecting nut

Incorrect operator technique Operator training

For Multichannel models

no leak

For the P2L to P200L Single models,

and the F1L to F250L Fixed models:

Fit a PIPETMAN DIAMOND Tip.

For the variable volume,set thepi-

pettetothemaximumvolumegiven

in the specifications, and pre-rinse.

Aspiratethesetvolumefromabeaker

of distilled

water.

Maintain the pipette in the vertical

position and wait for 20 seconds.

If awater droplet appears atthe end

of the tip there is a leak.

If you see no droplet, re-immerse

the tip below the surface of water.

Thewater levelinside the tip should

remain constant; if the level goes

down there is a leak.

For the P1000L, P5000L and P10mlL

Singlemodels,fortheF300LtoF5000L

Fixed models:

Fit a PIPETMAN DIAMOND tip.

For the variable volume, set the

pipette to the maximum volume

given in the specifications.

Aspirate the set volume from a

beaker of distilled water.

Maintain the pipette in the vertical

position and wait for 20 seconds.

If awater droplet appears atthe end

of the tip, there is a leak.

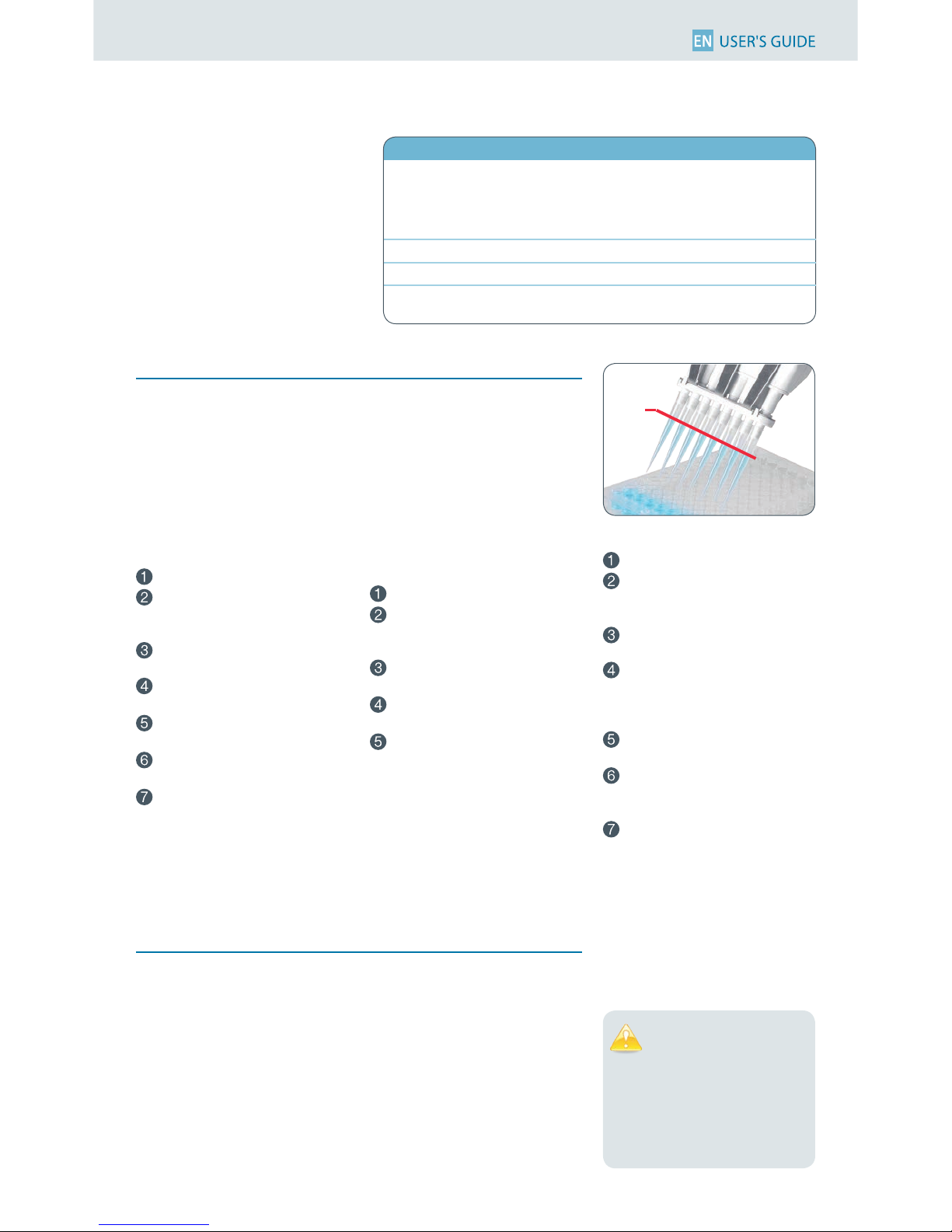

FortheMultichannel models (8x-12x):

Fit the PIPETMAN DIAMOND tip.

Set the pipette to the maximum

volume given in the specifications,

and pre-rinse.

Aspirate the set volume from a

reagent reservoir of distilled water.

Maintain the pipette in the vertical

position and wait for 20 seconds;

uid level in tips shoulds remain

constant.

If awater droplet appears atthe end

of the tip, there is a leak.

If you see no droplet, for volumes

below 200 µL, re-immerse the tip

below the surface of water.

Thewater levelinside the tip should

remain constant; if the level goes

down there is a leak.

12A MAINTENANCE FOR THE SINGLE AND FIXED MODELS ONLY

Routine maintenance will help keep your pipette in good condition, ensuring a

continued high level of performance.

Maintenance is limited to:

Cleaning or decontamination (see Chapter 13 - Cleaning and Decontamination)

Replacing spare parts

Greasing the piston assembly.

PIPETMAN P2L and P10L, F1L, F2L, F5L and F10L should not be disassembled,

so you may only replace the push-button, tip-ejector, dual position tip-ejector and

its adapter. With these pipettes if the tip-holder is damaged, the piston may also

be damaged.

After replacing any parts you

should verify the performance

of your pipette following the

verification procedure available

on the Gilson website (www.

gilson.com). If the pipette needs

to be readjusted, please contact

your local Gilson authorized

Service Center.