Page 5 of 49

BASIC SYSTEM OVERVIEW

1.

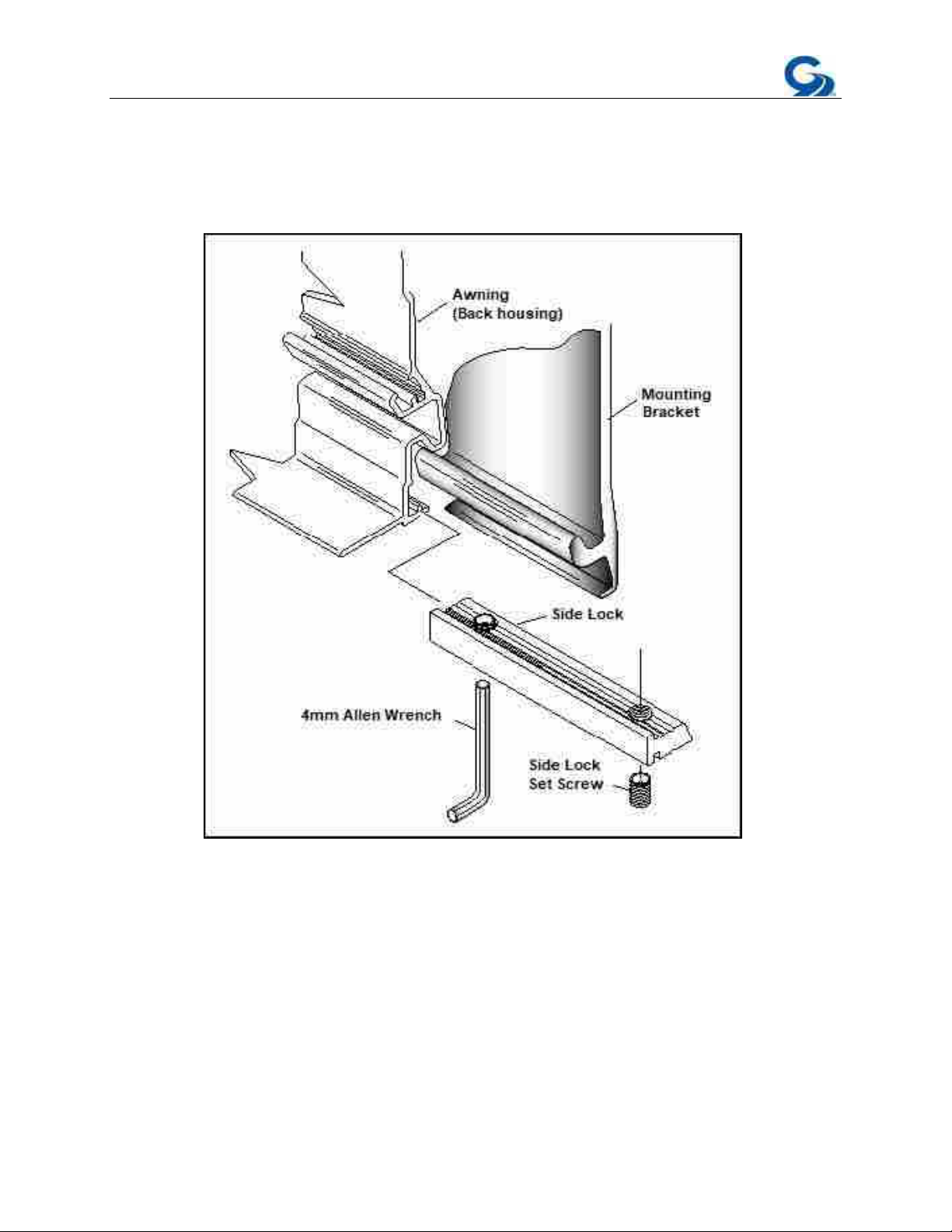

Mechanical system – consisting of:

•The enclosure (or cassette) protects the awning while closed.

•The roller tube which is mounted within the cassette.

•The top cover or fabric rolled onto the roller tube and connected to the lead

rail that extends from the enclosure when the awning is opened.

•The folding arms that supports the lead rail and the fabric.

•(Option) tubular motor which is mounted inside of the roller tube that controls

the extension and retraction of the awning.

•(Option) manual crank handle and drive system that controls the extension and

retraction of the awning

2.

Electronic controls – (Option) to power and operate the motor

•Motion Sensor – 98GC779, which enables automatic retraction of the awning

during periods of high wind that may damage the awning syste

m.

• Wired Motion Sensor – 98GC780B, Wired motion sensor that works in

conjunction with 98GC781B and 98GC783B wired wall switch controllers.

•Motor Control module – 98GC1146C. This works in conjunction with the other

electronic controls and the user controls included in the installation to extend and

retract the awning as required.

3.

User Controls – (Option) Hand held remote controllers and wall mounted

remote switches will differ according to the individual customer’s needs, single or

multi-channel handsets, with or without LED switching facility, and wall switches

will differ depending upon how many awnings they are required to control.

•98GC104 – Single channel awning remote control

•98GC1063 – Single channel remote with LED switching

•98GC229 – Single channel remote wall switch

98GC781B – Wired wall switch controller

•

•

C783B –

8G9Wired wall switch controller

•98GGC101 – Dual Rocker Switch