GIULIANO PRESS ARM User manual

Other GIULIANO Tyre Changer manuals

GIULIANO

GIULIANO S224 Technical Document

GIULIANO

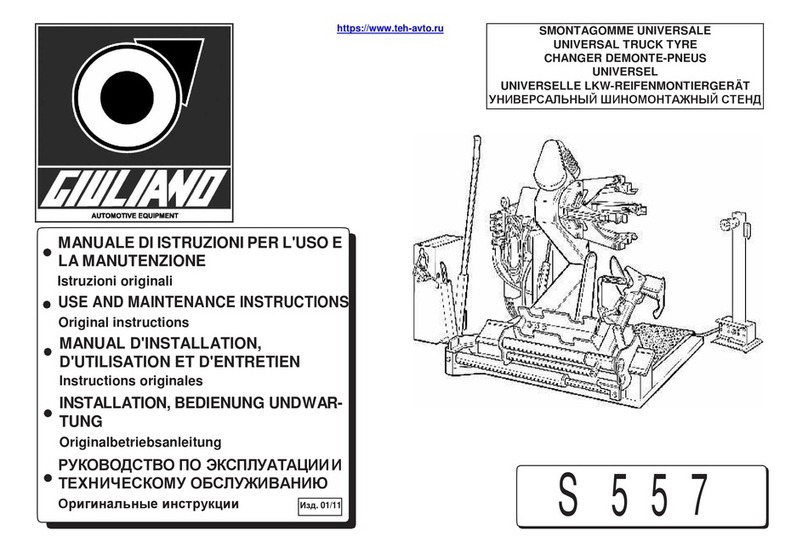

GIULIANO S 557 Operation instructions

GIULIANO

GIULIANO S 554 Operation instructions

GIULIANO

GIULIANO S 561 Operation instructions

GIULIANO

GIULIANO S 560 Operation instructions

GIULIANO

GIULIANO Crossage User guide

GIULIANO

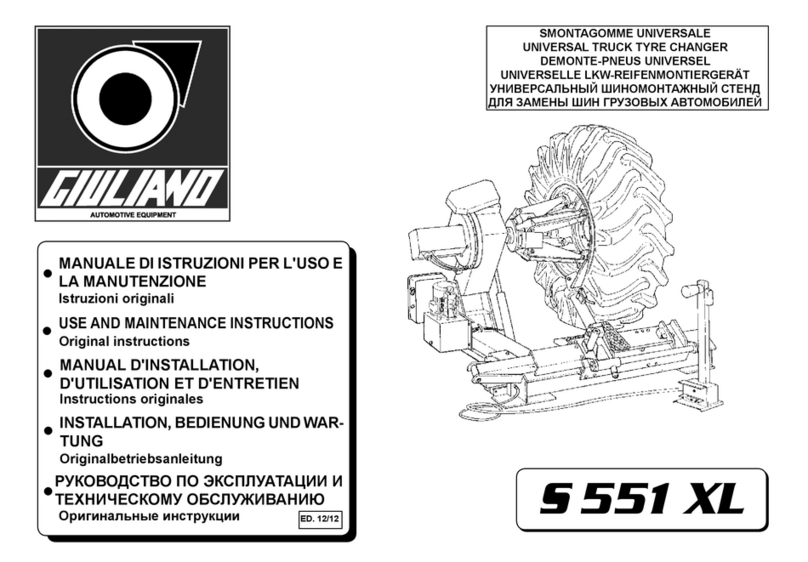

GIULIANO S 551 XL A Operation instructions

GIULIANO

GIULIANO S 226 Instruction manual

GIULIANO

GIULIANO S 551 XL A Operation instructions

GIULIANO

GIULIANO G1 SPORT User manual

Popular Tyre Changer manuals by other brands

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats Rim Clamp X-Model Series instructions

Draper

Draper 78612 user manual

Aston Global

Aston Global ATC-5800 Installation, Operation and Maintenance User’s Manual

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats CHD-4730-4730W Operating and maintenance instructions

Butler

Butler NAV11N instruction manual

Ranger

Ranger R76LT Installation and operation manual