-1-04111

D-Tect 2

GJD300 Quad PIR Movement Detector

Package Contents

Package Contains:

●1 x D-Tect 2

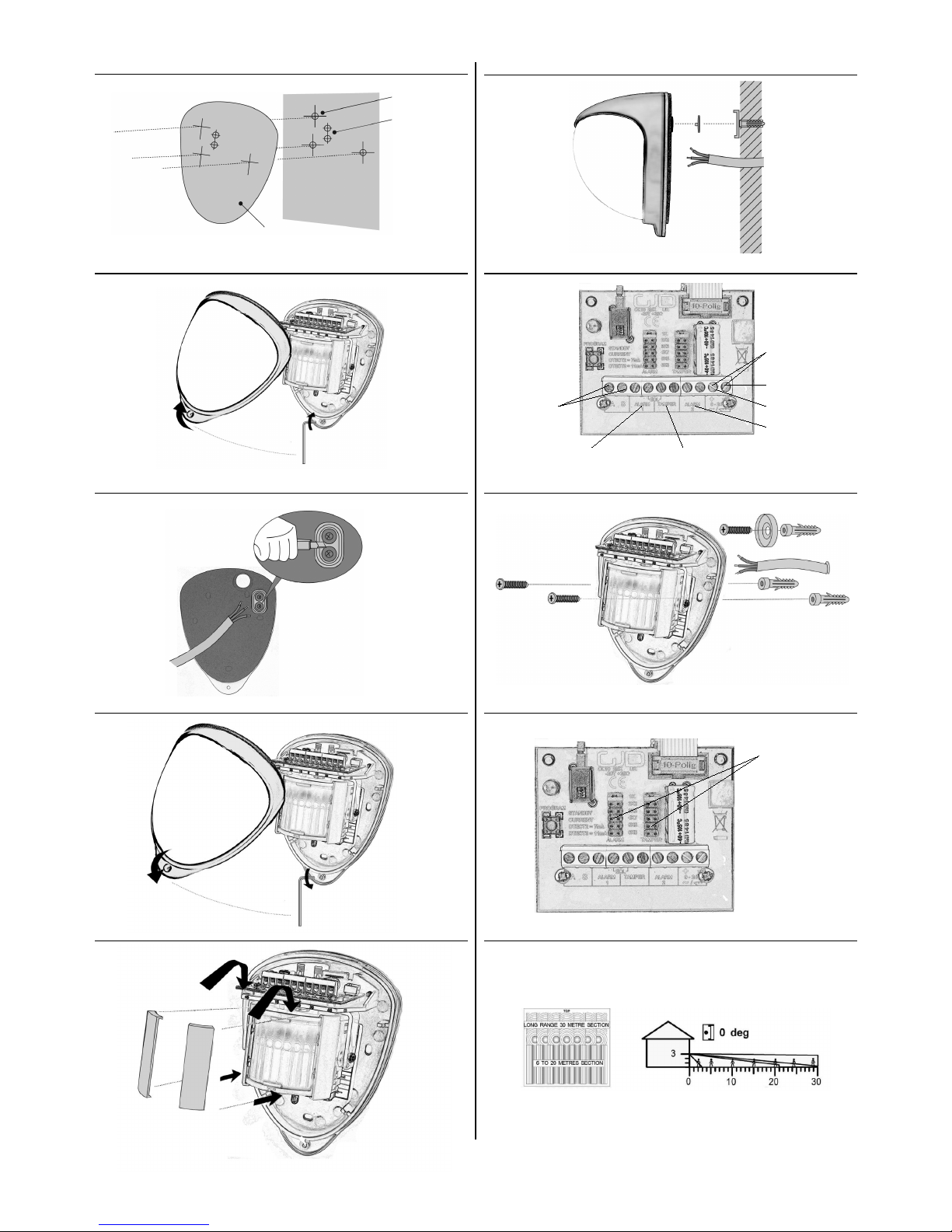

●1 x Drilling template for fixing holes

●1 x Allen Key

● x 1.75mm wall plugs

● x 1.75mm screws

●2 x Spare Sliding Curtains

●2 x Tamper Feet

●1 x Tamper Cup

●1 x Installation manual

Introduction

The D-Tect 2 is an outdoor motion detector and alarm

trigger that uses two independent passive infra-red

detectors, both of which must trigger to cause the detector

to signal an alarm. Utilising quad PIR technology, the D-Tect

2 delivers precise, reliable presence detection.

. Feed standard eight-core alarm cable into the

cable entry. Bare the wires and connect to the top

PCB terminal block. See Figures 2, 4 & 5.

4. Screw the unit to the wall ensuring that the rear

tamper pin is correctly located and that the tamper

microswitch is closed. See Figure 6.

To aid installation, two spare tamper feet are

provided. One is 1mm longer and the other is 2mm

longer than the tamper foot originally fitted. The

tamper foot is a push fit and can be removed by

carefully pulling it from the pin. See Figure 2.

5. When the detector is aligned, connected, and

programmed to suit the installation, replace the

front cover and lock as shown. See Figure 7.

The multifunction lens fitted to D-Tect 2 produces seven

long range beams and seven medium to short range curtain

PIR beams. The PIR circuitry detects changes in heat and

movement in the beam pattern; therefore items such as

trees, shrubs, ponds, boiler flues, and animals should be

considered when positioning the detector.

Note: The PIR sensor is more sensitive to movement

across the beams, and less sensitive to movement directly

towards or away from the beams.

The detector module is fitted with two sliding shutters to

reduce the detection angle.

The curtains are fitted to the pan and tilt module as shown

in Figure 9 (shown with primary and additional curtain

sliders fitted). Each section of the detector lens gives a

coverage pattern of approximately 10 degrees.

An additional set of curtain sliders is provided should the

beam pattern need to be narrowed even further, e.g. if the

minimum detection angle of 10 degrees is required.

When coverage exceeds the desired detection area, adjust

the module as required and mask off any beams, either

vertically or horizontally, to avoid unwanted detection.

Quick Installation

1. Mount and connect the detector following the

instructions given later in this sheet.

2. Apply supply voltage to the unit. The detection LED

(blue) flashes three times.

. Wait approximately 2 to minutes to allow the

detector to settle.

4. Press the programming button once to activate

walk test mode. The detection LED is now enabled

for five minutes.

Note: The front cover must be fitted when walk

testing.

The default settings are:

●Range: 20 meters

●Pulse count: 1 (always set to 1 during walk test)

●Detection LED: off (always enabled during Walk

Test)

●'S' Lux Level: 5

●Contacts:

●Alarm 1: Normally Closed

●Alarm 2: Normally Open

●Contacts Timer: 5 (seconds)

Mounting The Unit

Multibeam Alignment & Masking

During installation, protect the electronics against water, as

trapped moisture can affect or damage the unit.

1. Drill the wall to accept the two fixing screws, the

cable entry, and the tamper cup (if used). See

Figures 1 and 2.

A hole-drilling template is provided.

Note: We recommend using the tamper cup on

uneven wall surfaces.

2. Remove the cover assembly by loosening the

locking screw using the allen key provided. The

cover hinges from the top and lifts out of the

location slot. See Figure .

The D-Tect 2 includes jumpers that allow you to configure

the internal end-of-line resistor values, when EOL resistors

are required. Values are 1K, 2K2, K , 4K7, 5K6 and 6K8

Ω. Figure 8 shows:

1. EOL resistor jumpers

2. Wiring points

Alternatively, you can remove the jumpers and connect a

discrete resistor directly to the alarm or tamper outputs, as

specified by the third-party equipment.

Connections

Connecting The Unit

Terminal Label Description

1A 24 hour -VE Output

2 S Dark -VE Output

, 4 ALARM 1 Alarm relay 1

4, 5 EOL End-of-line resistors

5, 6 TAMPER N/C Tamper relay, normally closed

7, 8 ALARM 2 Alarm relay 2

9, 10 9 -24V AC / DC Supply