-3-

Changing The Random Code

In the unlikely event of another radio signal interfering with and

affecting the correct operation of a single RF channel, the D-Tect

X MKIII is able to generate an alternative random code.

To do this, press the Program Button on the D-Tect X MKIII nine

times. On the ninth press, ‘hold’ down the button for 5 seconds

until the LED goes out, then release the button.

Erase the existing code from the receiver by holding down the

Channel Button until the alarm LED ashes, then repeat steps

3 to 6 of the CODE LEARNING procedure to program in the new

code.

Code Learning

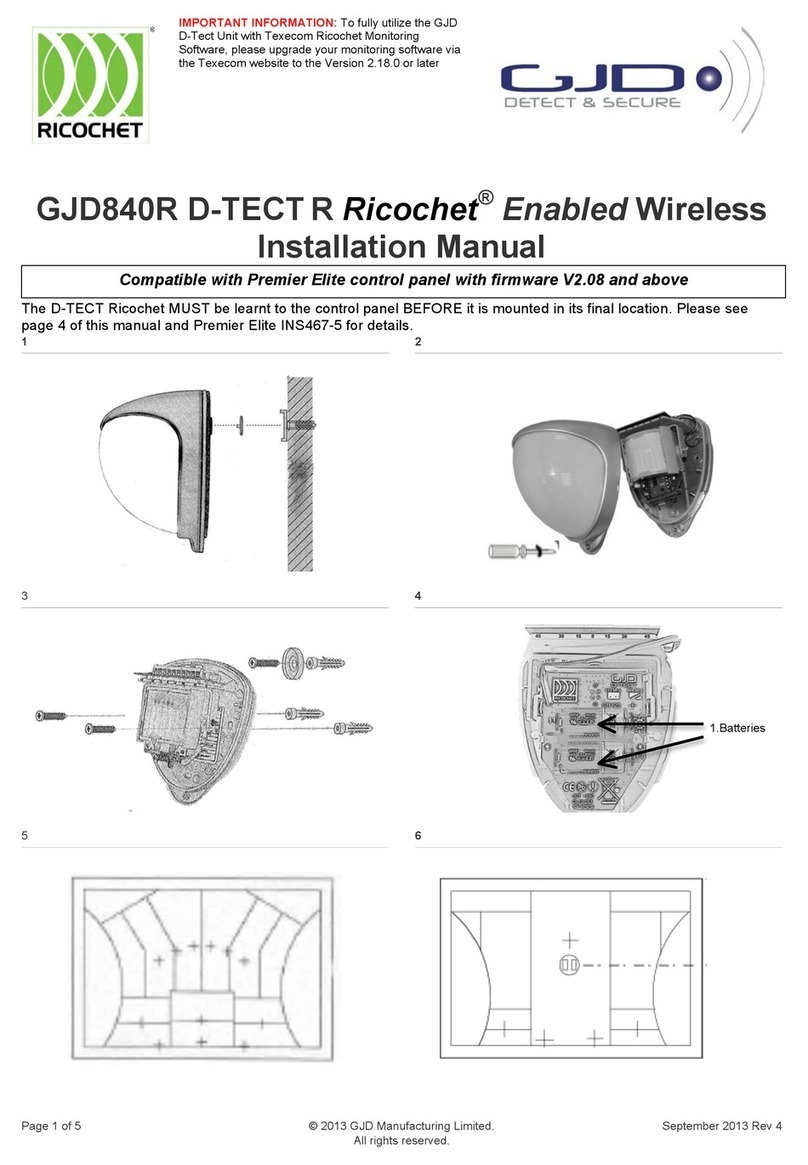

Before the detector is mounted in its desired position, the

detector and receiver must be able to communicate with each

other, therefore the detector’s identication and communication

codes must be transferred to the relevant channel in the receiver

unit in the following way:

1. Connect a 12-24 volt power source to the receiver

and insert the 2 x CR123 lithium batteries into the

detector. Always check that the batteries have been

inserted correctly. When powered up the detector takes

approximately 2-3 minutes to stabilise and the red LED

in the detector will ash 3 times when the power is

connected.

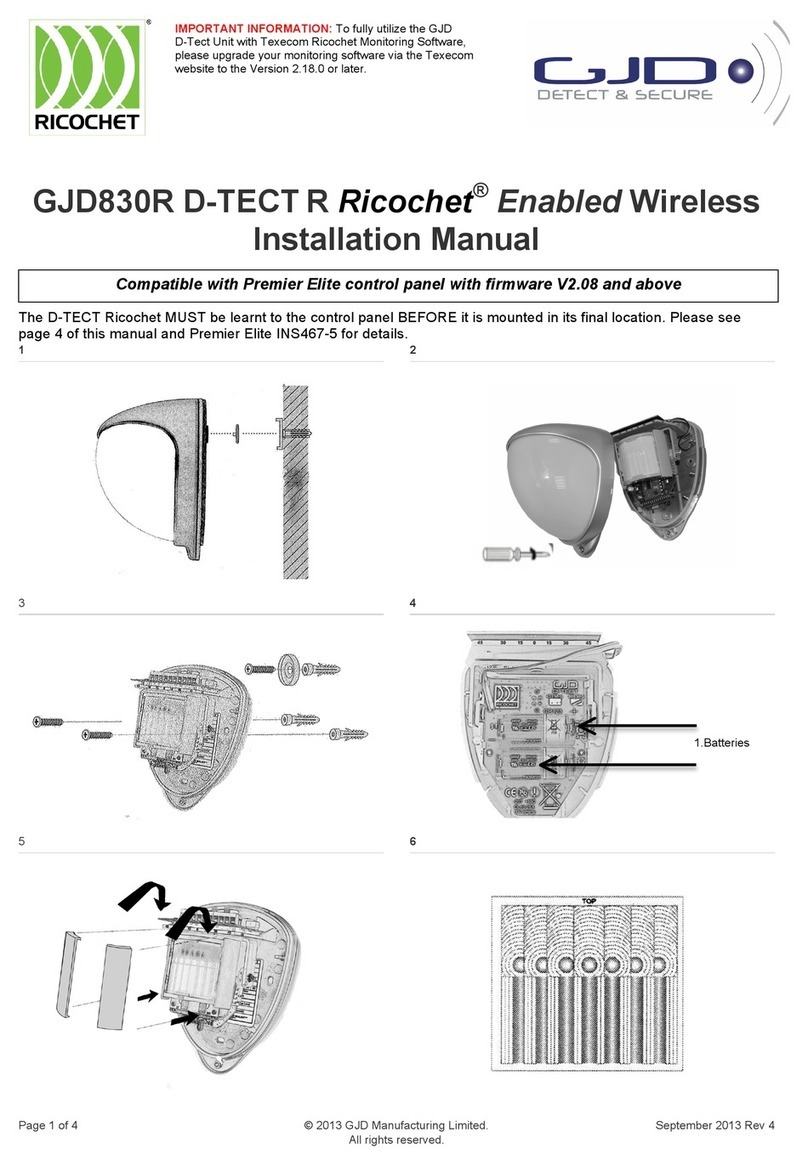

2. Plug in the Program Link Wire from the detector into the

code transfer socket in the receiver (see Figure 7).

3. Press the ‘Program button’ on the detector once (see

Figure 8) The red LED will light.

4. Immediately press the respective ‘Channel button’ on the

receiver module once and the LEDs will light up for the

selected channel. When the red LED on the detector turns

off the code is transferred and the 3 LEDs on the selected

channel will ash. The code has now been transferred

from the detector to the receiver.

5. Remove the link wire from the receiver module and plug

it into the Tamper PCB Connector on the top of the

detector (see Figure 6). Repeat steps 2 to 5 for all the

detectors to be on the receiver module. The receiver box

is equipped with one 4 way PCB module as standard, but

can accept up to 3 additional expander modules in total.

As each module can communicate with 4 detectors, each

receiver box is able to monitor 16 separate wireless D-Tect

X detectors.

6. To verify that a code has been stored for any individual

detector, press the appropriate Channel button on the

receiver module once and 4 LED’s will ash 3 times to

indicate a code has been stored.

7. To delete a code from a channel, press and hold the

Channel button; all 4 LEDs will light. Keep the Channel

button pressed for approximately 4 seconds until the

alarm LED ashes, then release the button. The channel

is now blank.

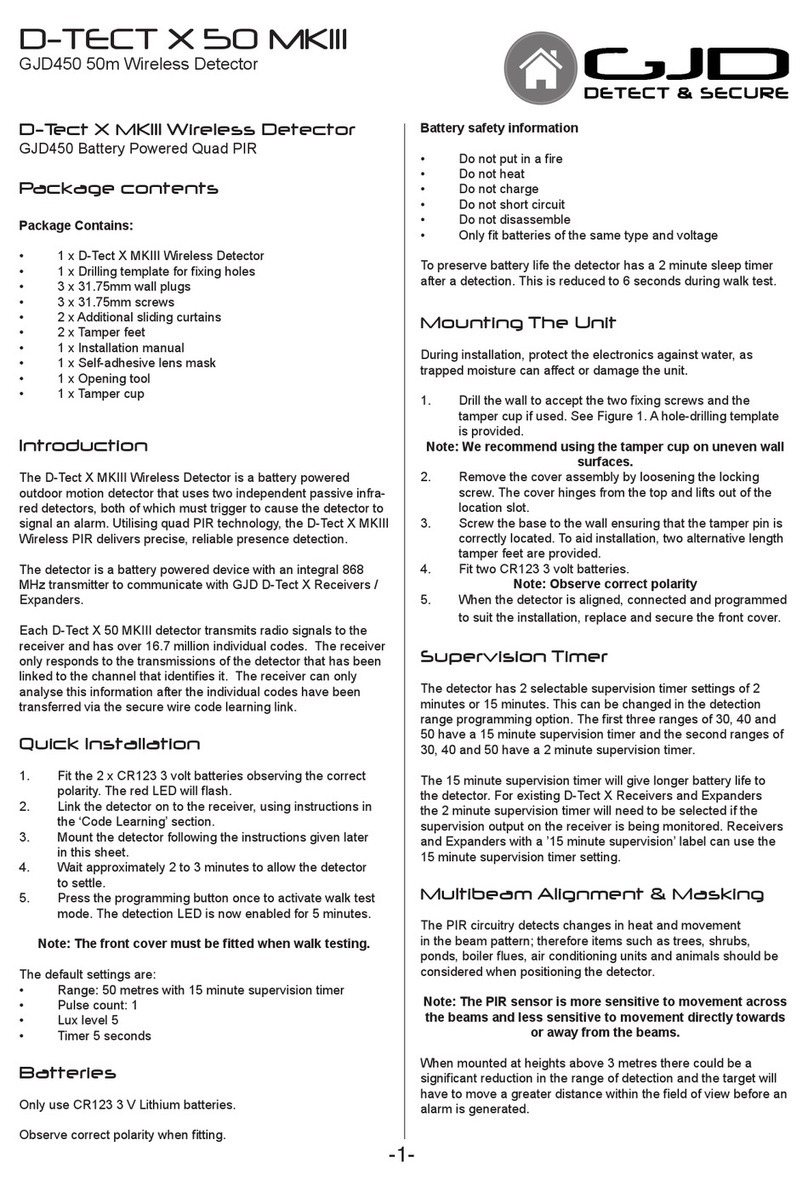

Walk Test

In walk test mode, the detection LED is set to ON. The detection

LED lights each time D-Tect X MKIII Wireless Detector detects

your presence.

To enter the walk test mode, press the programming button once.

The unit can then be aligned. The detection LED lights on D-Tect

X MKIII Wireless Detector every time detection takes place.

The test mode ends automatically ve minutes after last

detection.

Note: When you conduct a walk test, make sure that the

front cover is in place. Do not conduct walk tests with the

cover removed.

The range of the detector increases without the protective front

cover. Therefore the front cover must be tted to establish the

correct beam pattern. Pan and tilt the lens module over the eld

of view to obtain the correct coverage area.

Tamper Protection

The D-Tect X MKIII Wireless Detector is tted with two tamper

switches to detect the front cover being removed and removal

from the xing surface. The ying lead on the rear of the D-Tect X

MKIII Wireless Detector PCB must be plugged into the top PCB

for the tamper switches to operate.

Detector Features

• There are independent front and rear tamper circuits which

are combined to provide a volt-free tamper alarm contact.

• The exibility of the various outputs and timers allows the

D-Tect X MKIII to be used in multiple situations without

the need for any further customised equipment – and of

course as these are wireless movement detectors the

installation work is minimal.

• The integral dual axis tilt sensor allows 180 degrees of

pan and 90 degrees of tilt. This increases the speed of

the outdoor installation and provides incredible accurate

aiming of the detection pattern, particularly important for

BS 8418 installations.

• The electronics module is acrylic coated for additional

component stability

• The sensors are encased in a vandal-resistant high impact

ABS housing with a UV stabilised translucent front cover,

ensuring the sensor is impervious to and unaffected by

adverse weather conditions.

• The combination of precision electronics, digital white light

lter and double shielding eliminates false and nuisance

alarms from the sun and othe visible light sources.

• When a low battery is detected a signal is sent to the

receiver unit which displays a low battery indication and

operates the ‘LOW BATTERY’ contacts for the relevant

detector.

• The D-Tect X MKIII design has a neat and aesthetically

pleasing appearance with no visible indication of the

orientation of the detector head.