6

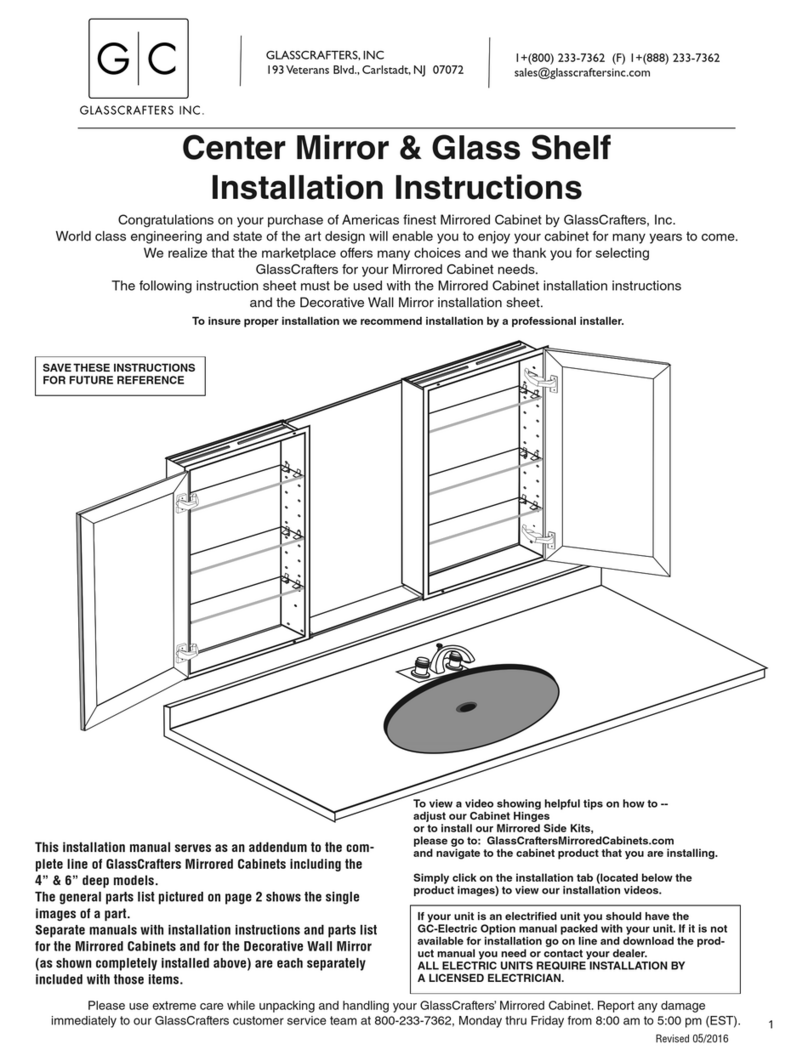

Installing a Surface Mounted Vertical Tier System Mirrored Cabinet

A. Determine the desired height and use a level to

mark a horizontal line. Be sure to allow a minimum

clearance of 1” above and below any light xture, ob-

struction and plumbing xtures. Remember the base of

the cabinet box is 3/4” smaller than the face and the

door.

B. After the bottom wall mount bracket is properly fas-

tened to the wall, unpack the VTS Wall Bracket, VTS-

Spacer, Plastic Wall Anchors and Screws from the

package.The VTS Spacer & Brackets will give you the

exact height for the top cabinet.

C. Determine the desired hinge side of the cabinet;

place the bottom cabinet into the bottom wall mount

bracket (see step 1). Place the VTS Wall Bracket on

the top ange of the bottom cabinet as illustrated (see

step 2). Mark and drill (2) 7/32” holes in the VTS Wall

Bracket. It is recommended that you try and locate a

wall stud to fasten the #10 x 1 1/2” Phillips head wall

anchor screws. Drill (2) matching holes into the wall

with a 3/16” masonry bit. Insert the #10 PWA Plastic

wall anchors into the wall holes and tap ush with the

wall.

D. Place the VTS Wall bracket into position and fasten

to the wall.

E. Clean the top section of the bottom medicine cabi-

net, free of any dust or debris.

F. The VTS Spacer is prepped with double sided

mounting tape and one strip of Decorative Chrome

Plated nish trim for the exposed spacing. Remove the

tape cover and carefully place the VTS Spacer on the

top of the bottom cabinet. The VTS Spacer is designed

to snugly t up against the frontedge. (See gure 2). The

two-sided tape is very strong; make sure you position

the VTS Spacer correctly before you apply adhesion

pressure. The VTS Spacer will be very difficult to remove

if installed incorrectly.

G. It is now time to place the top cabinet into position.

Make sure the hinges are on the same side as the bot-

tom cabinet. Slide (2) Top Surface Mount Brackets (425-

00) into the top-mounting groove. It is recommended to

dry t the cabinet into position before removing the tape-

from the VTS Spacer. Mark the top holes for the top sur-

face mount brackets, drill and install (2) plastic wall

anchors #10 PWA. You may have to adjust the VTS Wall

Bracket Screw to t the top cabinet into position.

H. Remove the tape from the VTS Spacer; carefully

place the top cabinet into position. Fasten the Top Sur-

face Mount Wall Brackets with (2) wall anchor screws

(Step 3). Make sure the VTS Spacer is ush with both

cabinets. Peel off the protective tape from the VTS nish

trim.

12

3