IMPORTANT:

Determine if your Tub/Shower

Stall Enclosure ledge is evel and

the Wall are plumb.

• 3/8” max. OOS (Out Of Square)

for the Door Side;

• 5/8”max. OOS (Out Of Square)

for the Panel Side;

• 3/8” max. OOS (Out Of Square)

on the Bottom (Base)

of the enclosure;

If your unit is Out-Of-Square or

Plumb greater than above STOP!

and call Customer Service.

The Phone number is

1-888-683-1362 .

2 3/4” MINIMUM CURB WIDTH

REQUIRED

When ordering replacement parts,please specify the Model Number, Item Number & Part Description.

Save these Installation Instructions For Future Reference.

Write your Dealer information down on Notes Section in the back of this guide. Ask your Dealer for JOB LOG NU BER

(Lxxxxxx-xxx) Referencing to your shower enclosure.

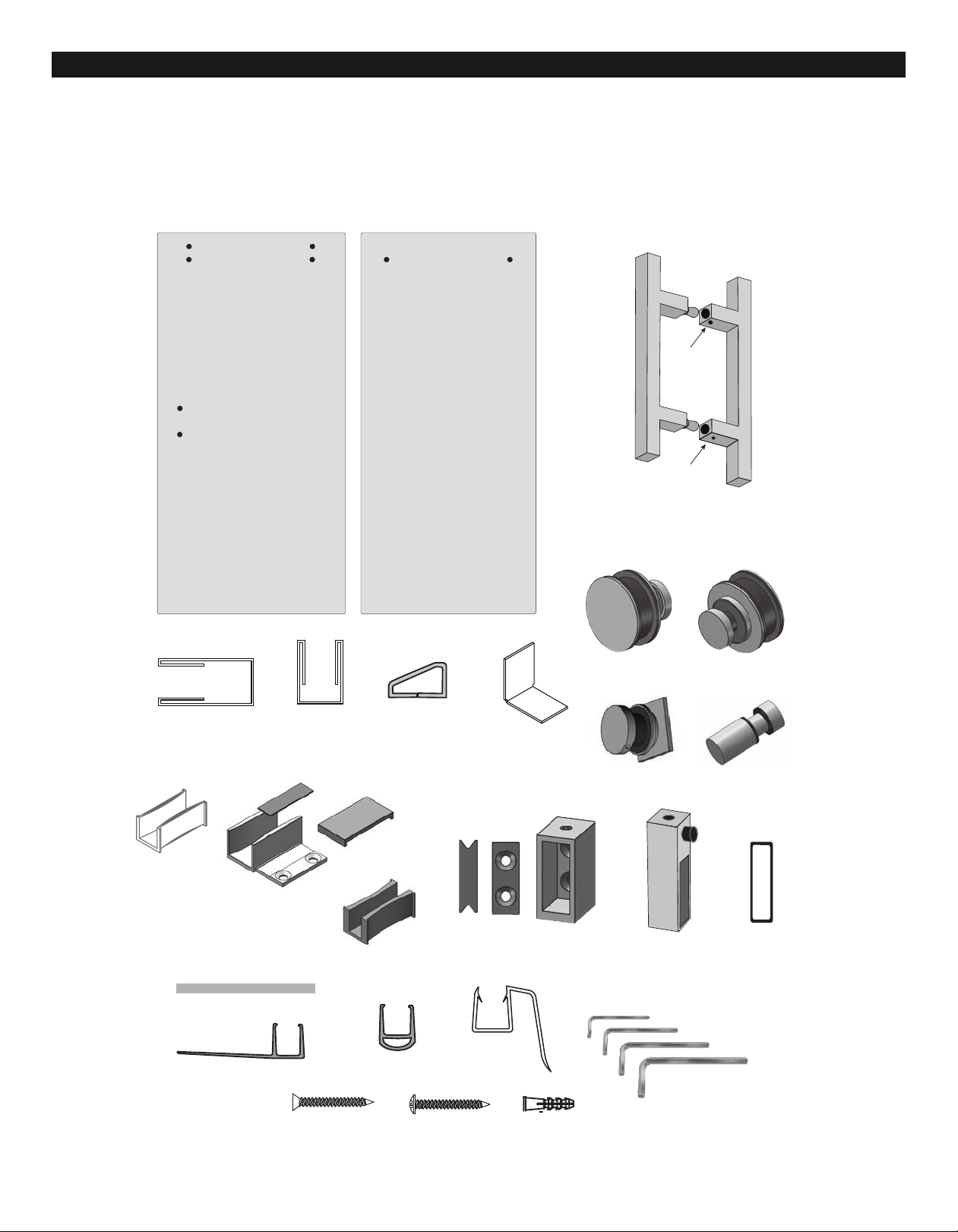

ITEM O. DESCRIPTIO QTY.

1 Vertical Wall Jamb ....................1

2 Fixed Glass Panel ....................1

3. Glass Door................................1

4. Door Handle Assembly .............1

6. Bottom “U” Channel..................1

7. Clear Setting Blocks .................3

8. Center Guide Assembly............1

9. Horizontal Rail .........................1

(with Panel Screw A embly ....

10. Horizontal Rail Mounting

Wall Brackets ..........................2

11. Plastic Guide Insert ..................1

12. Door Stop/Bumper....................2

13. Roller Assembly ........................2

14. Panel Screw Assembly .............2

(with Header ............................

15. Anti-Lift Standoff Assembly.......2

16. Clear “Bubble” Vinyl Bumper ....1

17. End Cap .................................1

18. Curb Dam .................................1

19. Clear “H” Vinyl .........................1

20. Plastic Wall Anchors.................12

21.Pan Head Screws, #8 x 1 1/4” ..7

22. Flat Head Screws, #8 x 1 1/4”..5

23. Hex Key Set (4)........................1

24. Splash Guard ...........................1

Parts Description

2

CAUTION: Risk of injury or product damage. Do not attempt to cut tempered glass.

IMPORTANT! Children should be supervised at all times while in Tub/Shower Enclosure.

IMPORTANT! Never use Door Handle or Towel Bar to support yourself. This is for towels or wash cloths only.

P EASE STOP THE INSTA ATION AND CONFIRM WITH FACTORY IF THE ACTUA NUMBER OR TYPE OF PARTS IS DIFFERENT

ASSEMB Y AND INSTA ATION

INSTRUCTIONS:

Gl sscr fters recommends the inst ll tion

be performed by tr ined inst ller.

• Read the manual and become familiar

with the steps involved in installation.

• This product requires Two persons for

safe installation.

• Always wear safety glasses during this in-

stallation.

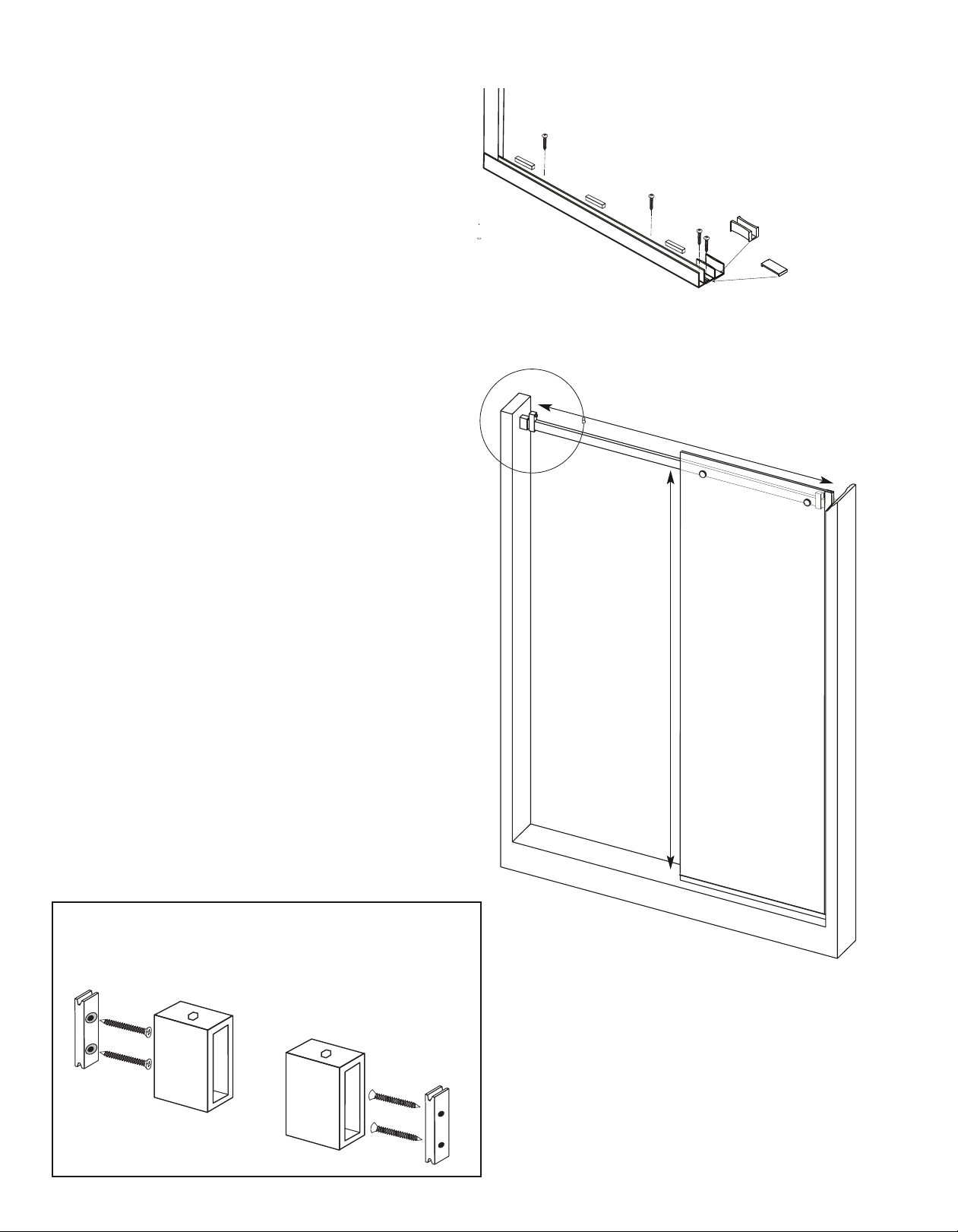

• The proper dimensions for this

installation were submitted at the time of

order. The Glass Panel and Door may

overlap to accommodate minor smaller

opening. One end of the Horizontal Rail

many be cut with a hacksaw for stainless

steel, but it must fit completely in the

Horizontal Rail ounting Brackets for a safe

installation.

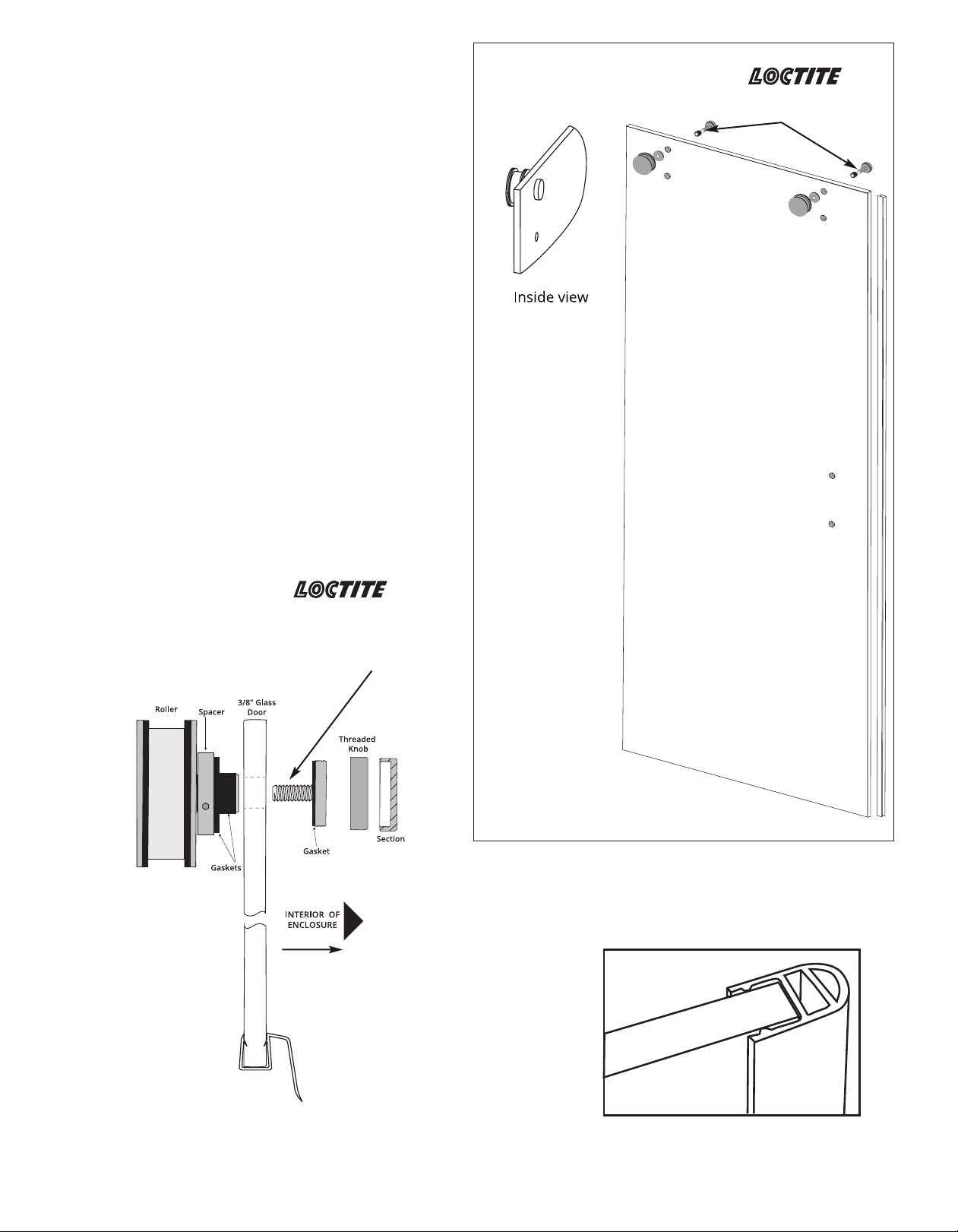

• When installing any mechanical parts

through the pre-drilled holes in the glass

door and panel be sure to use the gaskets

and bushings supplied between any metal

element and the glass. Do no over-tighten

any fittings.

• The glass used in this enclosure is

Tempered Safety Glass and features a

Tempered Safety Glass logo. Do not install if

Tempered Safety Glass logo is missing.

Call Customer Service.

• Tempered Safety glass cannot be cut,

ground, polished or manipulated in any

way.

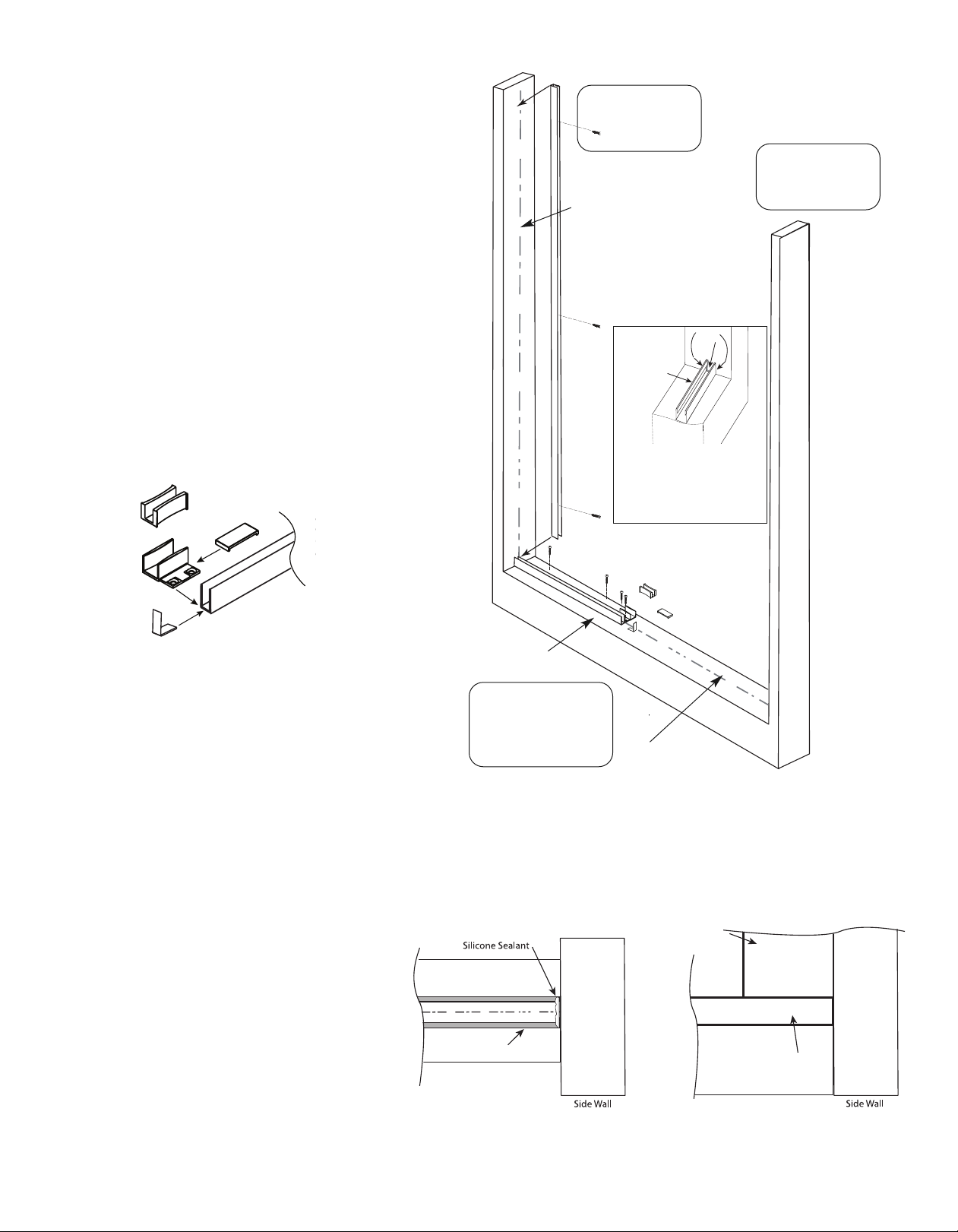

• If the installation is over ceramic tiles the

wall Jamb must lay flat on these tiles for the

entire height of the unit.

• Silicone Sealant is used to seal some parts

during installation and the inside of the

enclosure as shown in Detail #10. Do not

caulk from the outside of the enclosure.

Tools Required - For installation of Your Shower Enclosure

Safety glasses

Measuring tape

Pencil

Hacksaw or chop saw

(for stainless steel)

Miter Box or

Square

Level

Electric Drill/

Power Screwdriver

Center Punch

Rubber Mallet

Drill bit,

5/16” masonry

(for installation

on ceramic tiles

or marble)

#2 phillips

screwdriver

Caulking gun

Cutting Pliers

Suction Glass Lifters

(rated for more than 100 lbs)

WARNING: TO INSTALL ON CAST IRON, FIBERGLASS, ACRYLIC

OR RESIN TUB OR SHOWER BASE-

-

Check with the tub or shower base

manufacturer to determine the tooling required.

LOCTITE

243

BLUE

Loctite 243 Blue

Threadlocker

Medium strenght