5

Global Manufacturing, Inc ®800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

AIR BLASTER SVIBRA T O R SVIBRA T O R S

Troubleshooting

Problem Probable Cause Solution

Vibrator

runs

slowly or

does not

operate

Air line is blocked, restricted, or is connected to

the exhaust port and not to the inlet port.

Remove restriction in the air line. Check for kinked air

line. Check hose connections.

Pipe or hose size is inadequate for distance from

compressor.

The air line should be at least equal to vibrator inlet

port.

Contamination is in the vibrator. Disassemble vibrator and clean.

Faulty control valve. Clean, repair, or replace.

Start valve should be within 6’ of vibrator.

Inadequate air supply to operate vibrator. Check compressor. Provide more volume of air to

vibrator.

Vibrator

makes

excessive

noise

Mounting is not rigid. Check mounting bolts, broken welds, or fatigue in

structure.

Mufer not used. Use exhaust mufer.

Hopper or bin is empty. Do not run vibrator on an empty hopper or bin.

Ball and/or raceway rings may be worn out. Rebuild vibrator with repair kit.

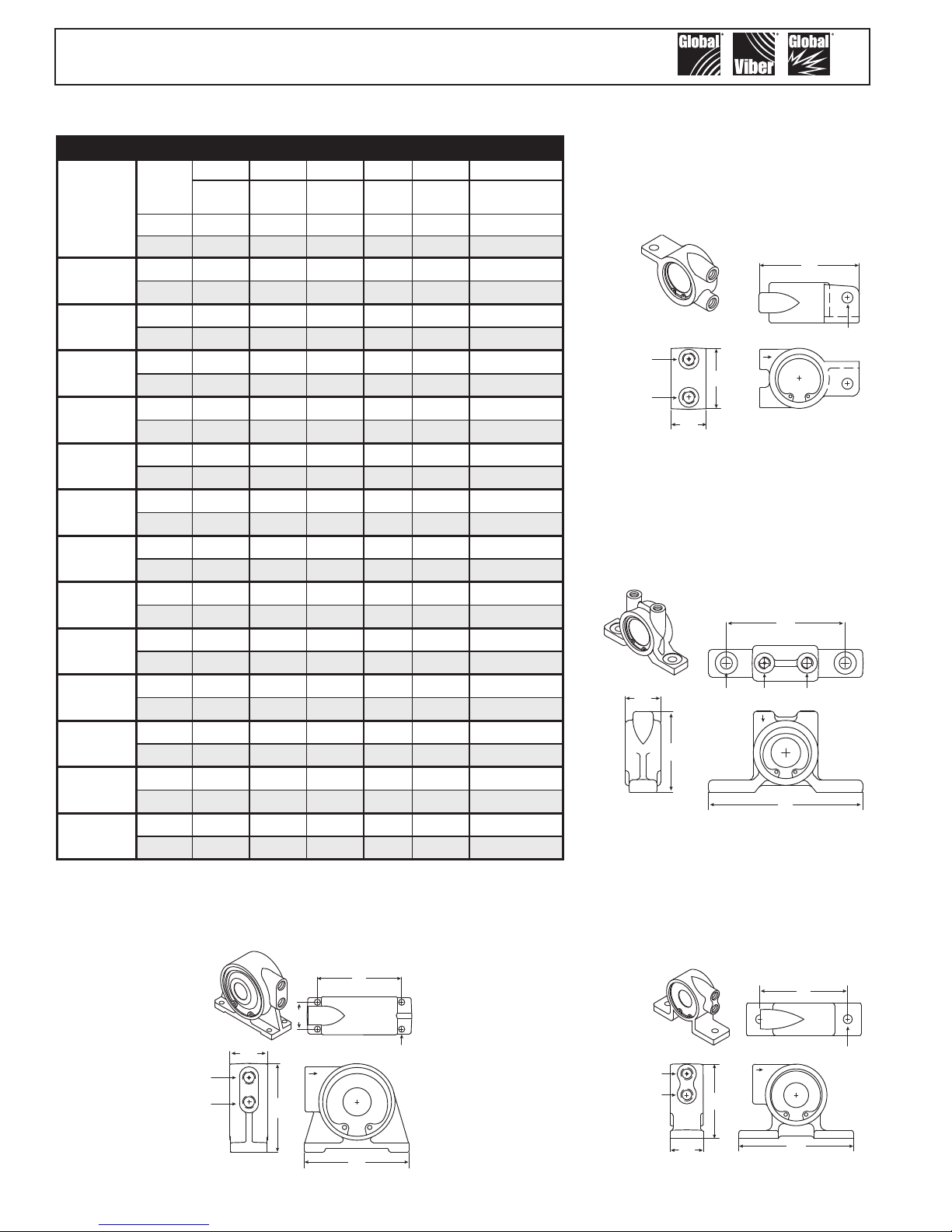

VI. Performance Data and Troubleshooting

Ball Vibrator Performance Data

Vibrator

Model

Unbalance

Air Pressure

Start Minimum 20 psi (1.4 bar) 40 psi (2.8 bar) 60 psi (4.1 bar) 80 psi (5.5 bar)

VERT HORZ SPEED FLOW FORCE SPEED FLOW FORCE SPEED FLOW FORCE SPEED FLOW FORCE

lb-in psi psi

rpm

cfm lb

rpm

cfm lb

rpm

cfm lb

rpm

cfm lb

kg-mm bar bar lpm N lpm N lpm N lpm N

BS-10

0.003 5 2

16,000 4.3 25 20,000 7.0 38 22,000 9.0 45 22,800 10.8 50

0.392 0.3 0.1 122 111 198 169 255 200 306 223

BS-16

0.020 15 7

9,400 4.1 50 13,000 6.4 93 14,000 8.2 110 14,800 10.0 124

2.30 1.0 0.5 116 222 181 414 232 489 283 553

BS-19

0.043 20 10

8,600 5.5 89 11,000 8.4 150 13,000 11.0 200 14,800 13.7 267

4.95 1.4 0.7 156 396 238 667 311 890 388 1190

BS-25

0.120 30 15

5,700 7.5 110 6,900 12.0 160 8,200 16.0 230 9,600 19.8 314

13.8 2.1 1.0 212 489 340 712 453 1023 561 1397

US-13

0.009 5 2

13,000 6.5 45 18,000 11.0 84 20,000 15.0 110 22,400 19.0 133

1.07 0.3 0.1 184 200 311 374 425 489 538 589

US-19

0.043 20 10

8,700 5.5 92 11,000 8.4 160 13,000 12.0 210

15,000

16.0 275

4.95 1.4 0.7 156 409 238 712 340 934 453 1222

US-25

0.120 30 15

6,300 7.0 140 8,400 12.0 240 9,100 16.0 280 9,600 20.0 314

13.8 2.1 1.0 198 623 340 1068 453 1246 566 1397

US-38

0.520 50 25

4,300 12.0 270 5,600 19.0 470 6,000 25.0 540 6,200 31.0 568

59.9 3.4 1.7 340 1201 538 2091 708 2402 878 2525

CS-19

0.043 20 10

9,100 5.7 100 12,000 8.4 170 14,000 12.0 220 17,000 15.7 353

4.95 1.4 0.7 161 445 238 756 340 979 445 1570

CS-25

0.120 30 15

6,300 7.8 130 8,100 13.0 220 9,200 18.0 290 10,000 22.3 341

13.8 2.1 1.0 221 578 368 979 510 1290 631 1516

CS-35

0.240 50 25

5,300 7.8 190 6,700 13.0 310 7,600 16.0 390 8,100 19.0 447

27.7 3.4 1.7 221 845 368 1379 453 1735 538 1989

DS-41

0.820 55 25

3,200 13.0 240 4,000 21.0 370 4,400 27.0 450 4,700 33.7 514

94.5 3.8 1.7 368 1068 595 1646 765 2002 954 2288

DS-51

1.300 60 30

3,100 13.0 350 4,000 20.0 580 4,300

27.0 680 4,400

33.7 715

149.8 4.1 2.1 368 1557 566 2580 765 3025 954 3179