GM

COACH

MAINTENANCE MANUAL

Page

5

INDEX

A

Page

Accessories,

Engine

• • • • • • • • • • • • • • • • • 142

Adjustments

Bearings,

Wheel

•••••••••••••••••••

Brake

Application

Valve

••.••••••••••

Brake Shoe

....................

.

Brake

Treadle

Clutch

.........................

.

Compressor

Unloader

Valve

•••••••••••

Drag

Link,

Steering

• • • • • • • • • • • •

•••

Fog

Lights . . . . . . . . . . . . . . . . .

.....

Generator

Neutral

Point

•••••.•••••••

Governor,

Air

Compressor

•••••••••••

Hand Brake

....................

.

Headlights

......................

.

Pressure

Regulating

Valve

•••••••••••

Regulator,

Generator

•••••••••••••••

Relays

........................

.

Safety

Valve

•••••••••••••••••••••

Steering

Gear

• • • • • • • • • • • • • • • •

••••

Stop

Screw,

Steering

Knuckle

•••••••••

Tie

Rod

........................

.

Windshield

Wiper

Valve

•••••••••••••

Air

Brakes

•••••••••••••••••••••••

Air

Cleaners,

Engine

••••••••••••••••

Air

Compressor

and

Governor

•••••••••

Air

Horns

.......................

.

Air

Intake

System,

Engine

• • • • • • • • • • • • •

Alarm

System,

Tell-tale

•••••••••••••

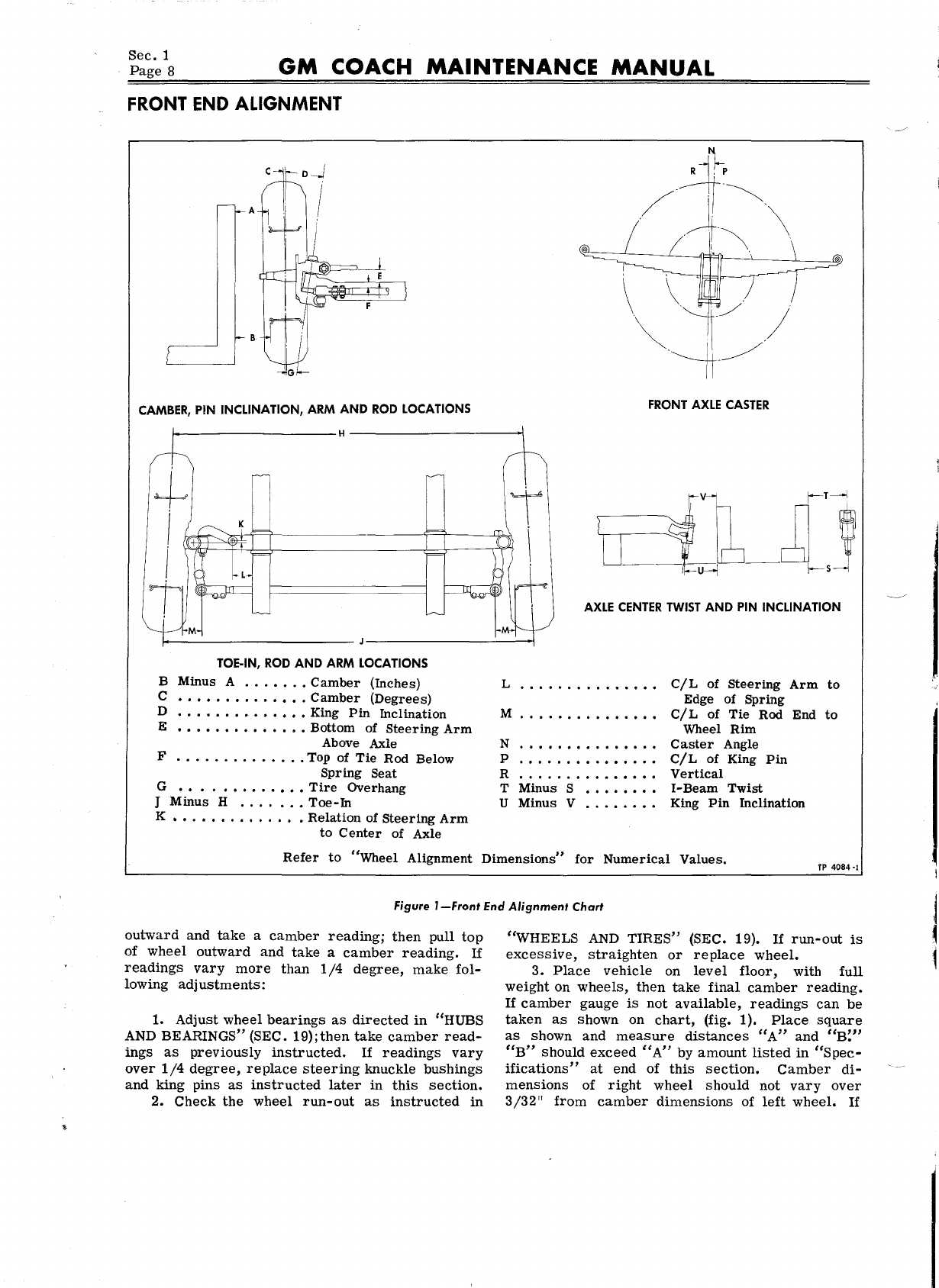

Alignment,

Front

End

• • • •

••••••••••••

Antifreeze

Chart

..................

.

Application

Valve,

Brake

•••••••••••••

Axle, Front

......................

.

Axle,

Rear

......................

.

B

199

51

44

44

179

71

177

134

125

71

75

133

48

128

109

45

171

10

10

38

43

151

63

38

150

107

7

98

48

7

17

Battery

• • • • • • • • • • • • • • • • • • • • • • • • • •

115

Battery

Junctions

••••••••••••••••••

, 106

Bearings,

Wheel

• • • • • • • • • • • . • • • • • • • 199

Body

• • • . • • • • • • • • • • • • • • • • • • • • • • . • 29

Body

Junction

Panel

• • • • • • • • • • • • • • • • • 104

Brake

Chambers

• • • • • • • • • • • . • • • • • • •

55

Brake

Drums

• • • • • • • • • • • • • • • • • • • • •

61

Brake,

Hand • • • • • • • • • • • • • • • • • • • • • • 75

Brakes,

Air . . . . . . . . . . . . . . . . . . . . . . . 43

Buzzer,

Tell-tale

Alarm

• • • • • • • • • • • • • • 107

C

Capacity,

Cooling

System

•••••.•••••••

Check

Valve,

Aux.

Air

System

•.•••••••

Check

Valve,

Compressor

Discharge

••••••

Chime,

Passenger

Signal

•••••••••••••

Circuit

Breaker

Panel

•••••••••••••••

Clutch

Compressor,

Air

. .

.....

Cl

• •

•••••••••

<;ontrol

Panel,

Driver's

••••••••••••••

Cooling

System

. . . . .

..............

.

98

48

46

39

102

179'""'

63

101

89

D

Page

Diesel

Engine

• • • • • • • • • • • • • • • • • • • • • 141

Doors

and

Controls

• • • • • • • • • • • • • • • • • 35

Drag

Link,

Steering

• • • • • • • • • • • • • • • • • 177

E

Electrical

System

•••••••••••••••••••

Electric

Horn

Emergency

Door

..................

.

Engine

Comp't.

Panel

•••••••••••••••

Engine

Mounting

•••••••••••••••••••

Engine

Tune-up

••••••••••••••••••.•

Entrance Door

.......

If

• • • • •

••••••••

F

Fan

and

Water

Pump

••••••••••••••••

Filter,

Fuel

Oil

.••••••••••••••••••

Filter,

Lubricating

Oil

• • • • • • • • • • • •

•••

Front

Axle

•••••••••••••••••••••••

Fuel

Oil

Specifications

•••••••••••••••

Fuel

System

••••••••••••••••••••••

Gauge,

Air

Pressure

Gauge,

Oil

Pressure

G

Gauge

Panel

.....................

.

Generator

.......................

.

Generator

Regulator

•••••••••••••••••

Glass

Replacement

••••••••••••••••••

Governor,

Air

Compressor

••••••••••••

H

Hand

Brake

Heating

.........................

.

Horn,

Electric

•••••••••••••••••••••

Horns,

Air

•••••••••••••••••••••••

Hubs

and

Bearings

• • • • • • • • • • • • • • • • •

99

113

35

105

145

141

35

97

149

143

7

154

149

46

142

100

121

126

36

71

75

39

113

38

199

Injector

Shut-off,

.Air

Operated

• • • • • • • • • 144

L

Lighting

System

••••.•••••••••••••••

Lights,

Tell-tale

.••••••••••••••••••

Links,

Shock

Absorber

•••••••••••••••

Low

Air

Pressure

Switch

•••••••••••••

Lubrication

Lubrication

Chart

M

Mato-Gard

........

"

..............

.

132

107

168

46

155

156

108

I