GENERAL INFORMATION OA-3

SERVICE PARTS IDENTIFICATION STICKER

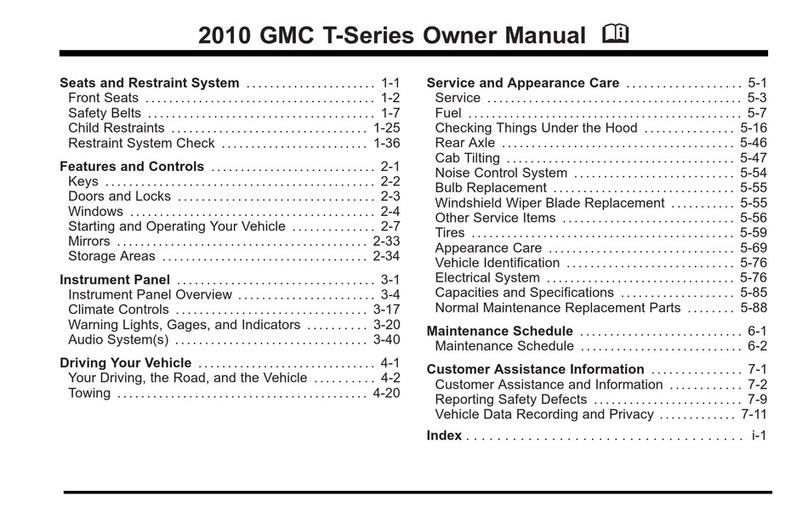

The Service Parts Identification Stic er (Fig. OA-6) is

provided on all Truc models. On C and K models, the

identification stic er be located on the inside of the glove box

door or on G model, the stic er will be located on an inner

hood panel surface. On P models, the stic er is located on a

inner body panel.

The plate lists the vehicle identification number,

wheelbase, and all Production options or Special Equipment

on the vehicle when it was shipped from the factory

including paint information. ALWAYS REFER TO THIS

INFORMATION WHEN ORDERING PARTS.

VEHICLE LOADING

Vehicle loading must be controlled so weights do not

exceed the numbers shown on the Vehicle Identification

Number and/or Rating Plate for the vehicle.

A typical example of a truc in a loaded condition is

shown in Figure OA-7. Note that the axle or GVW capabili

ties are not exceeded.

ENGINE CODE NUMBER

The engine code number indicates producing

plant, month and day of manufacture, and transmission

type. A typical engine number would be F1210TTBB, which

would brea down thus:

F - Producing Plant (F-Flint, T-Tonawanda)

12 - Month of Manufacture (December)

10 - Day of Manufacture (tenth)

T - Truc

TBB - Transmission and engine type

UNIT AND SERIAL NUMBER LOCATIONS

For the convenience of service technicians and engi

neers when writing up certain business papers such as

Warranty Reports, Product Information Reports, or report

ing product failures in any way, the location of the various

unit numbers have been indicated. These unit numbers and

their prefix or suffix are necessary on these papers for

various reasons - such as accounting, follow-up on produc

tion, etc.

The prefixes on certain units identify the plant in which

the unit was manufactured and thereby permits proper

follow-up of the plant involved to get corrections made when

necessary.

Always include the prefix in the number.

SERVICE PARTS IDENTIFICATION

V.I.N | ■ mu-- H i

V 1 N - VlMlCli IDENTIFICATION NUMBER

NOTE I THE SPECIAL EQUIPMENT LIS

PARTS BE SURE TO SPECIF'

TED BELOW MAS BEEN INSTALLED ON

IDENTIFIC A TION OF REPLACEMENT

THE APPLICABLE OPTION NUMBERS

DE SCR IPTIO N OPTION D E SCR IPTIO N

■■

Axles

Chevrolet Built

• On 10 Series, the Code is stamped on Top of Right

Rear Axle Tube.

• On 20-30 Series, the Code is stamped on Top of the

Right Rear Axle Tube.

Dana Built

• On Front Axles, code is stamped on Top Rear of Left

Axle Tube.

• On Rear Axles, code is stamped on Rear Surface of

Right Axle Tube.

Transmissions (Fig. OA-6)

• On 3-Speed Transmissions (except Tremec), the Unit

Number is located on Lower Left Side of Case Just

Below Cover.

• On Tremec Transmissions, Unit Number is located on

Upper Left Attachment Case (Top Side).

• On Muncie 4-Speeds, Unit Number is located on Rear

Face of Case below Retainer.

• On New Process 205 model 4-wheel drive transfer case,

a build date is on tag attached to front face of transfer

case.

• On Automatic 350 Transmission, Unit Number is

Located on Right Rear Vertical Surface of Oil Pan.

• On the Automatic 400 Transmission, Serial Number is

Located on the Light Blue Plate on the Right Side of

the Transmission.

• On the Automatic 700R4 Transmission, the

Unit Number is stamped on the cover pan rail

on the Right Side of the Transmission.

I PORTANT: RETAIN THIS PLATE AS A PER ANENT RECORD

L O A D E D -M A X IM U M G VW R: 4900-LBS.

FRONT GAWR: 2944 LBS. REAR GAWR: 2944 IBS.

Front urb

Front argo &

Pass. Load

2219 lbs.

284 lbs.

*Rear urb

Rear argo &

Pass. Load

2503 lbs.

1003 lbs.

1394 lbs.

2397 lbs.

TOTAL WEIGHT AT GROUND: 4900 lbs.

* urb weight equals the weight of the vehicle without driver,

passenger or cargo, but including fuel and coolant.

Fig. 0A-4-Service Parts Identification Plate Fig. 0A-5--Typical Vehicle Loading ondition