10 PHH 1001 | Version 2.03

Care, maintenance and repair

Lowering the load

To lower the fork, pull the control lever for the hydraulic

pump to the upper position and hold it: The fork is lowe-

red.

When released, the lever automatically returns to the

middle position.

When the load is safely lowered and the fork is free, ex-

tend the pallet truck under the load.

Lifting and lowering the load can be interrupted at any

stage of the operation. The load is held securely in its

current position.

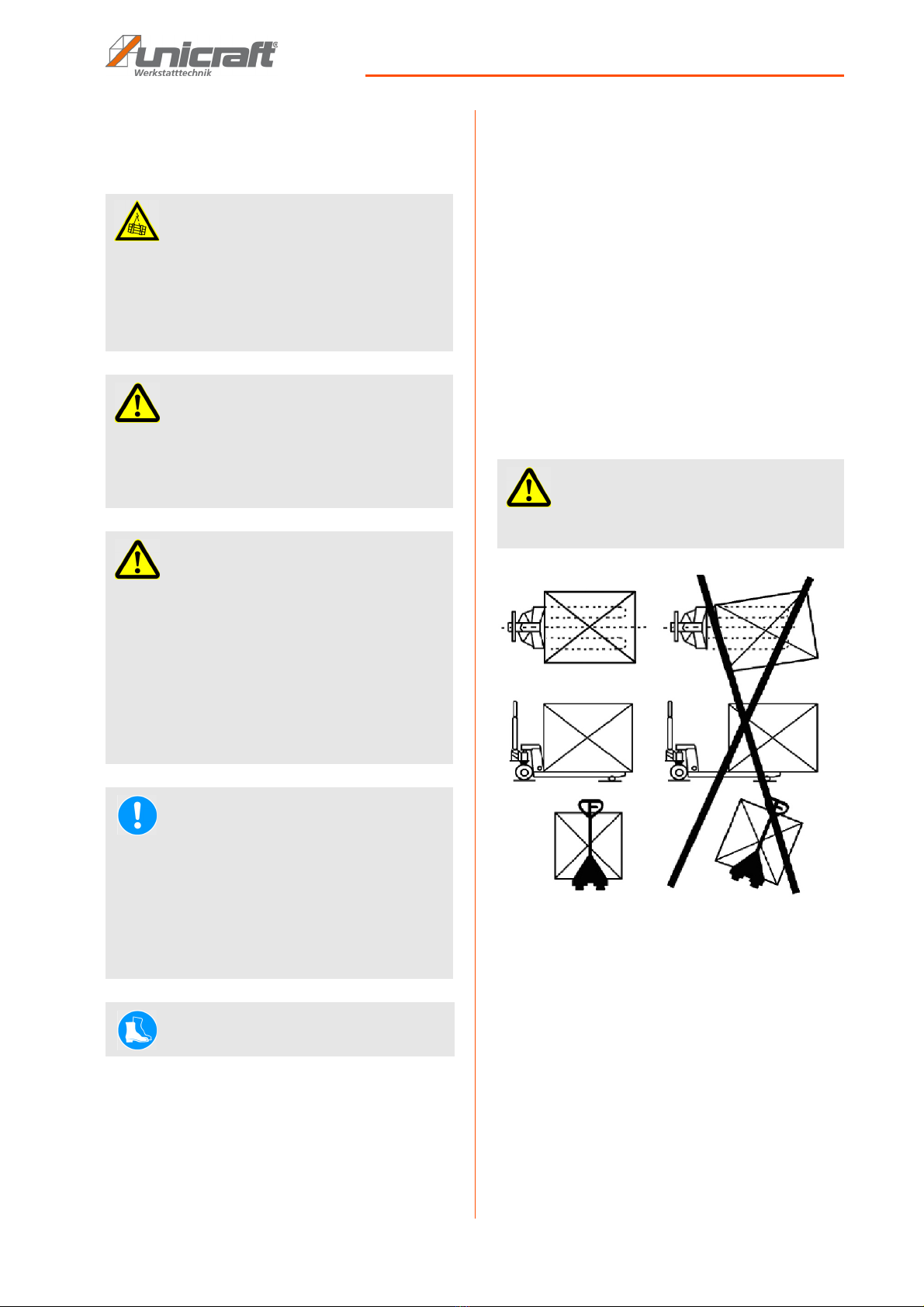

Manoeuvring the pallet truck

To manoeuvre the pallet truck, always move the control

lever for the hydraulic pump to the middle position. This

makes manoeuvring easier and increases the service

life of the seals in the hydraulic pump, as it is ineffective

in the middle position of the lever.

To manoeuvre the pallet truck, push or pull it, for lateral

movements turn the control drawbar to the right or left

while doing so.

In order to protect the wheels and the chassis of the

pallet truck, do not drive over large uneven surfaces

(potholes, thresholds, etc.).

To lift the forks, push the control lever for the hydraulic

pump into the lower position, the lever engages. Then

move the control drawbar up and down, the forks are lif-

ted.

To lower the forks, pull the control lever for the hydraulic

pump into the upper position and hold, the forks are

lowered. When released, the lever automatically returns

to the middle position.

Lifting and lowering the load can be interrupted at any

stage of the operation. The load is held securely in its

current position.

If the pallet truck gets out of control on a slope, the pallet

truck can be braked by carefully lowering the load.

10 Care, maintenance and repair

10.1 Care by cleaning

The scissor pallet truck must always be kept in a clean

condition.

All plastic and lacquered surfaces should be cleaned a

soft, damp cloth and a neutral cleaning agent.

10.2 Maintenance and repair

The mechanical and general condition of the pallet truck

must be checked by a specialist workshop at least

every 12 months.

Maintenance work may only be carried out by qualified person-

nel with mechanical knowledge.

ATTENTION!

Risk of injury!

Do not place body parts (hands, feet) under the

forks or between the scissors when a load is lifted or

lowered.

ATTENTION!

- Never move the pallet truck on a slope or sloping

surface.

- Observe different surface structures

- The load must be secured against falling down.

- Observe the longer stopping distance corres-

ponding to the load. Use the brake, if available.

ATTENTION!

- Maintenance and repair work may only be carried

out by qualified personnel.

- Before starting cleaning and service work, remove

the load and place the forks in the lowest position.

Park the pallet truck firmly and secure it against

rolling away.

- Only use original spare parts.

- Oil leaks can cause damage and accidents!

- Adjustment of the pressure valve may only be car-

ried out by qualified service technicians.

- Waste materials such as oil, used batteries must be

disposed of in accordance with local regulations or

handed over to a recycling company.

- Before completing maintenance work, ensure that

all cables are correctly connected and all safety

covers are correctly fitted.

Use protective gloves!

NOTE!

Never use strong cleaning agents to clean the de-

vice. Such cleaning agent might damage or destroy

the device.

ATTENTION!

All protective and safety devices must be reinstalled

immediately after completion of repair and main-

tenance work.