GENERAL INFORMATION OA-1

T"™“" " —^^ ^ ^ M mma——m i

SECTION OA

GENERAL INFORMATION

CONTENTS

SUBJECT PAGE

Special Tool Ordering Information

Service Parts Identification Label

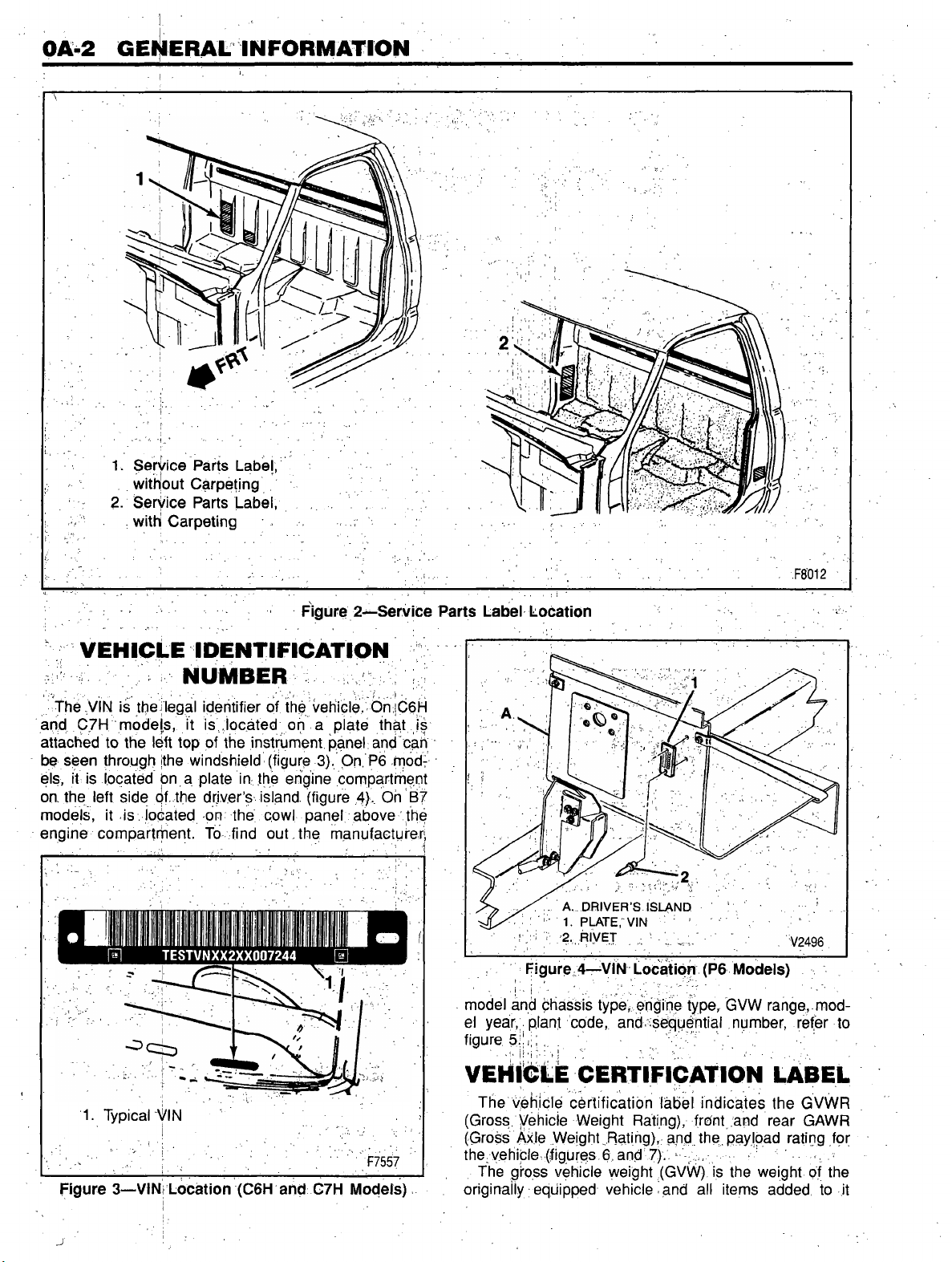

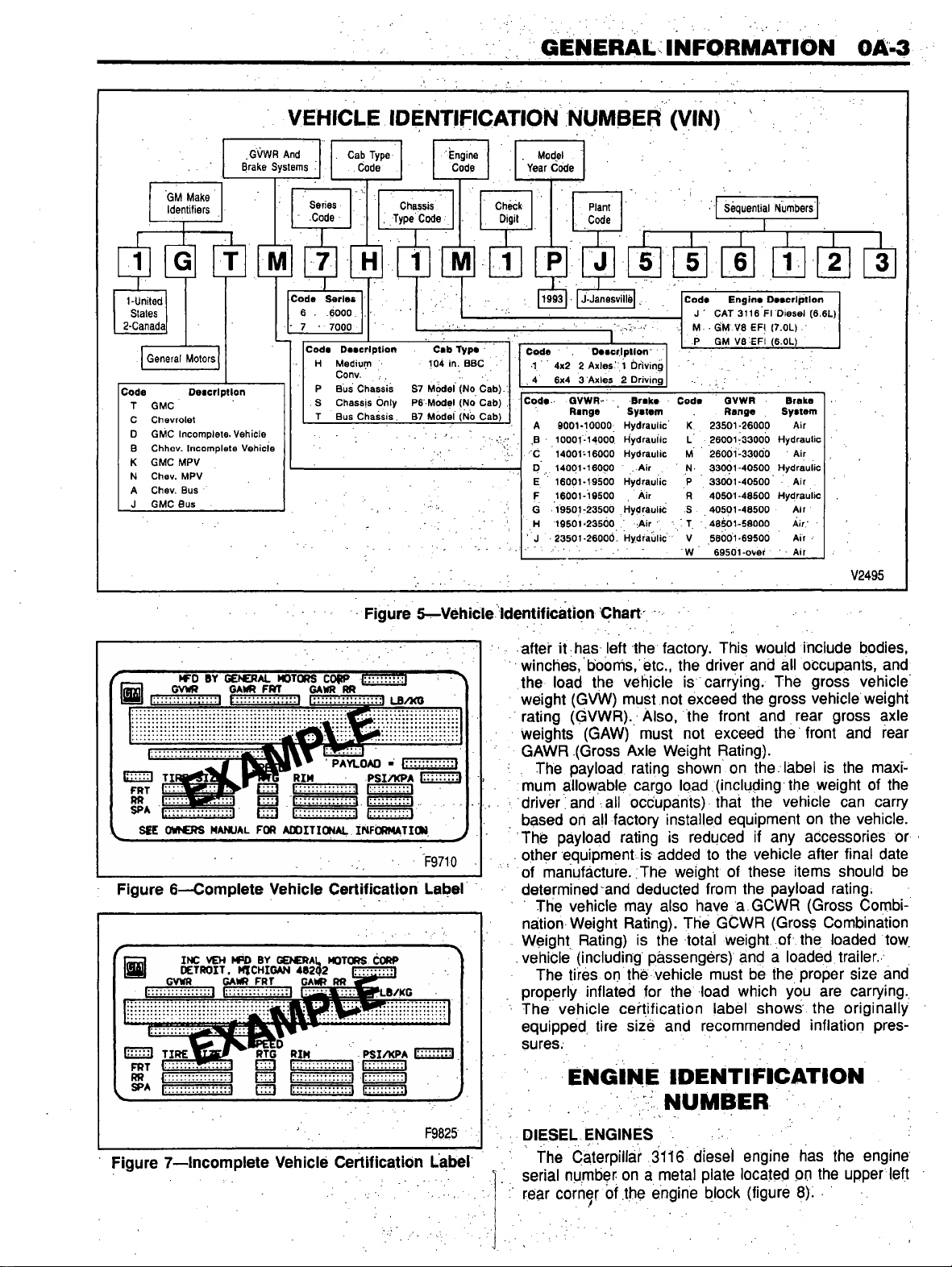

Vehicle Identification Number

....

Vehicle Certification Label..........

Engine Identification Number

....

Diesel Engines

..........

...........

Gasoline Engines

...................

Rear Axle Identification Number

Rock ell......................................

Eaton

...........................................

Transmission Identification Number

Allison

.........................................

Eaton-Full e r

..................

.............

Model Identification

......................

Metric Fasteners

...........................

Fastener Strength Identification.

Prevailing Torque Fasteners

......

Metric-English Conversion

.....

Decimal and Metric Equivalents

J1930 Word Conversion

..............

■>

OA- 1

OA- 1

OA- 2

OA- 2

OA- 3

OA- 3

OA- 4

OA- 4

OA- 4

OA- 5

OA- 5

OA- 5

OA- 5

OA- 5

OA- 5

OA- 8

OA- 8

OA- 9

OA- 9

OA- 9

SPECIAL TOOL ORDERING

INFORMATION

Special service tools that are sho n in this service

manual have tool product numbers beginning ith “J”

or “BT" are available for orld ide distribution from:

Kent-Moore

SPX Corporation

29784 Little Mack

Roseville, Ml 48066-2298

1-800-345-2233

Mon.-Fri. 8:00 p.m. EST

Telex: 244040 KMTR VR

Fax: 313-578-7375

General Motors dealers can purchase TECH 1

scan tools and accessories through Kent-Moore at

the above address and phone number. Non-General

Motors dealer repair facilities can purchase TECH 1

scan tools and accessories from Kent-Moore at the

above address or :

Sun Electric Corporation

One Sun Park ay

Crystal Lake, IL 60014

1-800-CALLSUN (225-5786)

6:45 a.m. - 7:00 p.m. CST

SERVICE PARTS

IDENTIFICATION LABEL

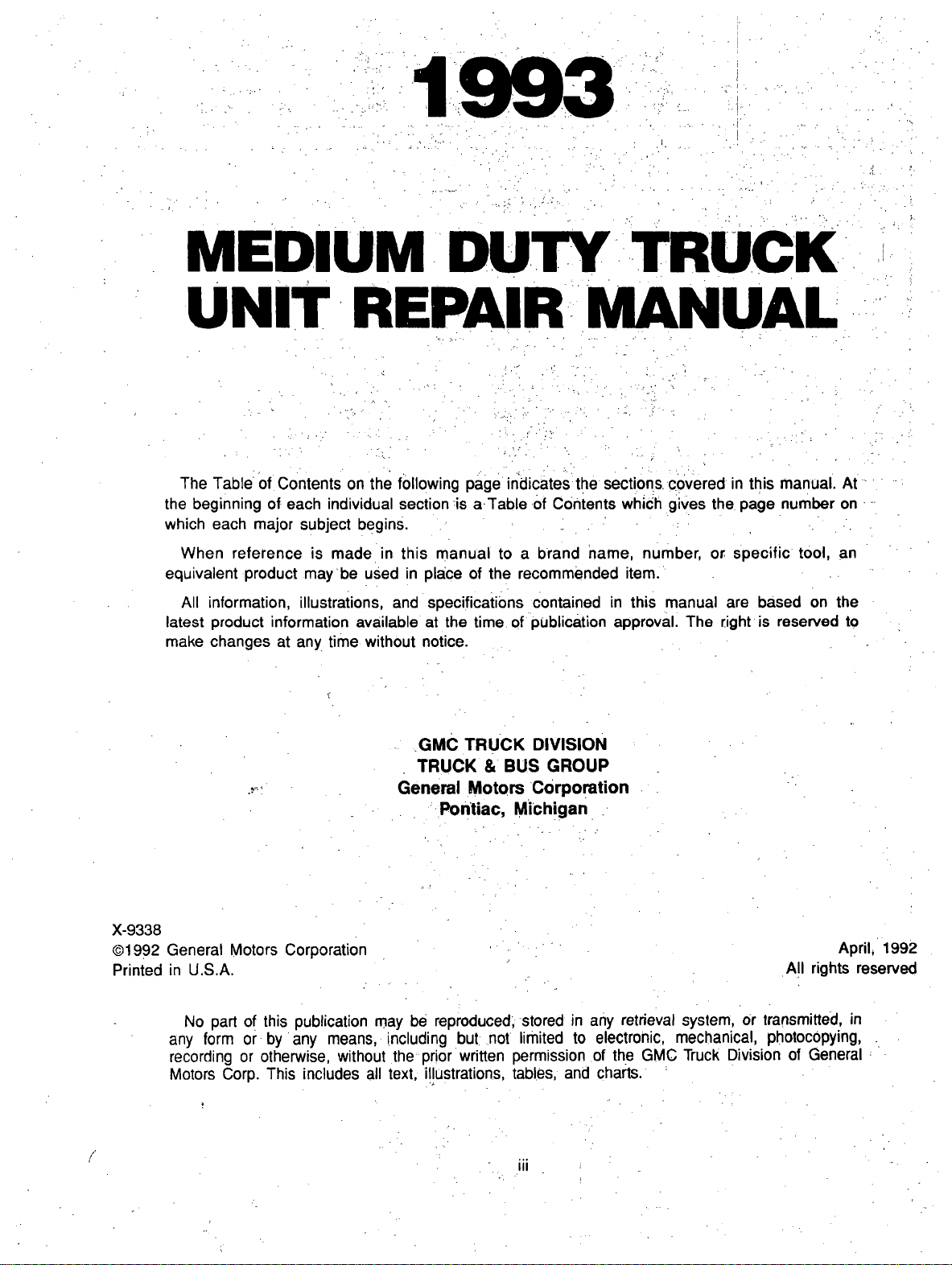

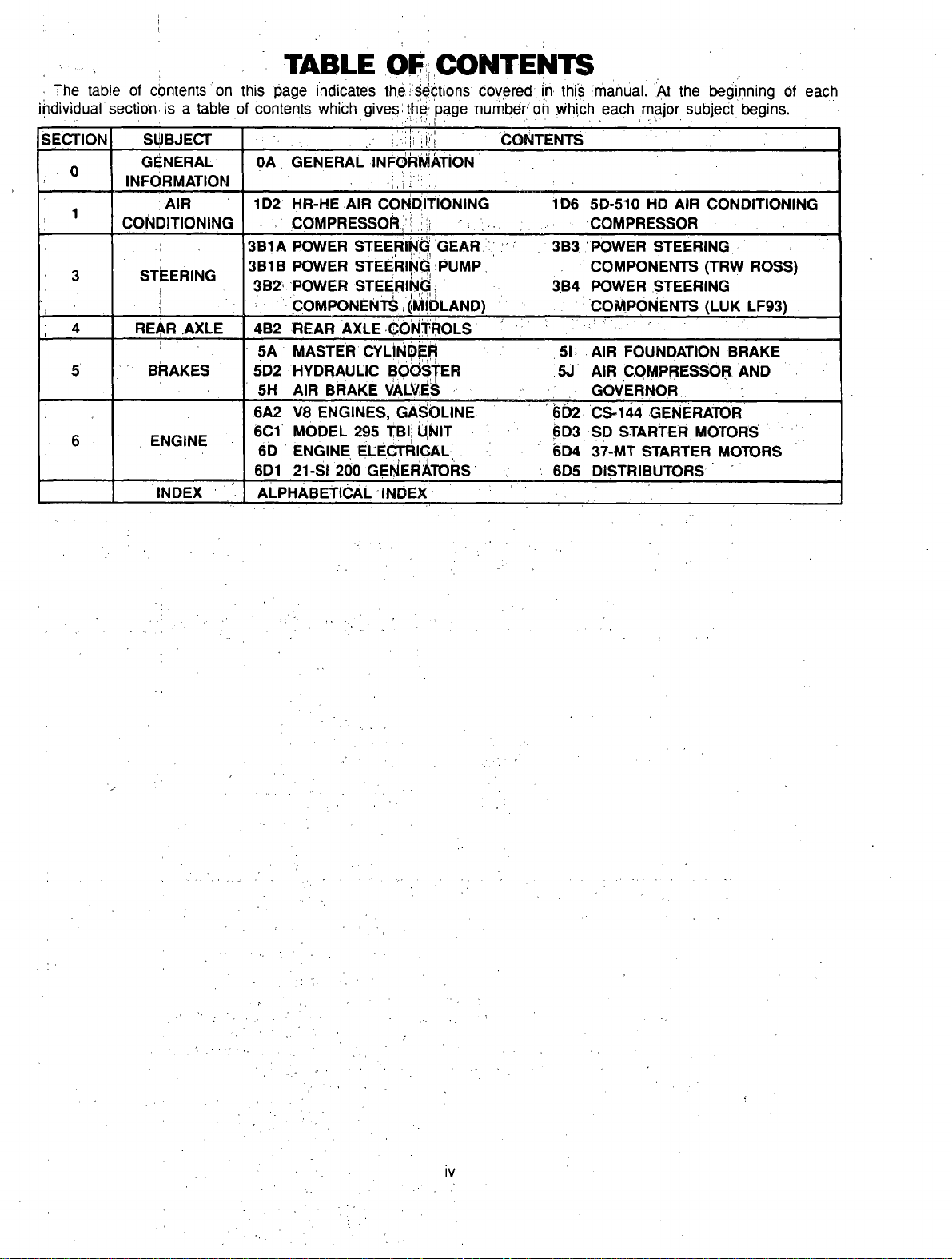

The service parts identification label is provided on all

vehicle models. On the conventional cab models (G6H

and C7H), the label is located on the side all of the

cab behind the passengers seat if the cab has carpet

panels. If the cab does not have carpet panels, the

jabel ill be located at the lo er corner of the passen

gers side of the cab all.

The label is placed on the P6 and B7 models by the

body manufacturer.

The label lists the VIN (Vehicle Identification Number),

heelbase, paint information, and all production options

or special equipment on the vehicle hen it as

shipped from the factory. ALWAYS REFER TO THIS

INFORMATION WHEN ORDERING PARTS (figures 1

and 2).

15516776

NOTICE. THIS INFORMATION IS SUPPLIED AS AN AID IN IDENTIFYING PARTS FOR SERVICE

SERVICE PARTS REQUIREMENTS FOR THIS VEHICLE MAY VARY FROM THOSE LISTED

BEFORE ORDERING ANY OK THE ABOVE PARTS. ALWAYS HAVE YOUR GENERAL

MOTORS TRUCK DEALER CHECK THIS VEHICLE'S BROADCAST SUPPLEMENT FOR

POSSIBLE PART CHANGES.

IMPORTANT: RETAIN THIS PLATE AS A PERMANENT RECORD

B5559

Figure 1—Service Parts Identification Label