4 ENGLISH Grindmaster®Model RC400

General Information

This operating manual includes instructions for using

and maintaining your coffee brewer; keep this manual

readily available.

After unpacking your brewer, check to ensure that your

machine has not been damaged during shipping and

includes all components. Notify your service

representative regarding any questions or concerns

before installing.

During various stages of operation, you may hear

normal operating sounds that are unfamiliar. The

following noises are normal:

Buzzing/Clicking - Heard when the water pump

energizes and/or the three way valve opens and

closes to dispense water or direct water to reservoir.

Popping – A damaged RealCup™ capsule could

result in a popping sound.

Pulsating/Whirring – Under normal operating

conditions, an internal air pump activates at the end

of a brewing cycle and you will hear it while

energized.

Water running or gurgling – On a pour over

installation, you will hear gurgling when reservoir

is empty before the end of a brew cycle. On an auto

fill installation, you will hear this sound as the

brewer automatically refills.

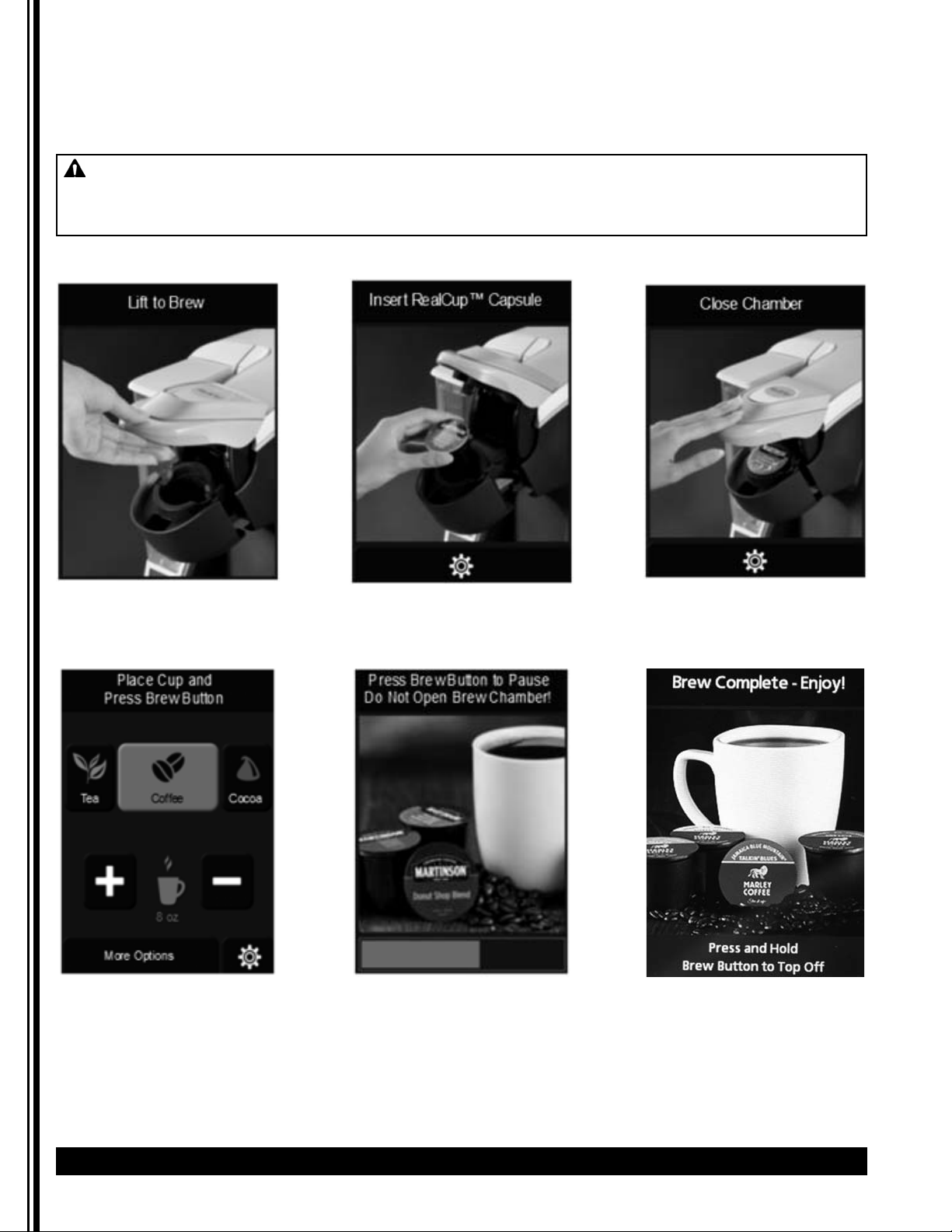

Do not use a damaged RealCup™ capsule or re-insert a

capsule that has been previously inserted & removed.

This may result in coffee grounds and unwanted

material inside the brew chamber and the drinking cup

or mug. Damage to RealCup™ capsule can include but

is not limited to damage around the edge of the foil

seal or denting and deformation of the RealCup™

capsule.

To ensure food safety and proper operation, clean

machine regularly following the daily and weekly

cleaning instructions. Cleaning and water evacuation

instructions are found in the Cleaning and

Maintenance section of this manual.

When turning off the machine for an extended period,

be sure to evacuate the water inside the brewer

completely. Otherwise, the water inside the machine

could freeze and lead to damage or cause mold to

appear.

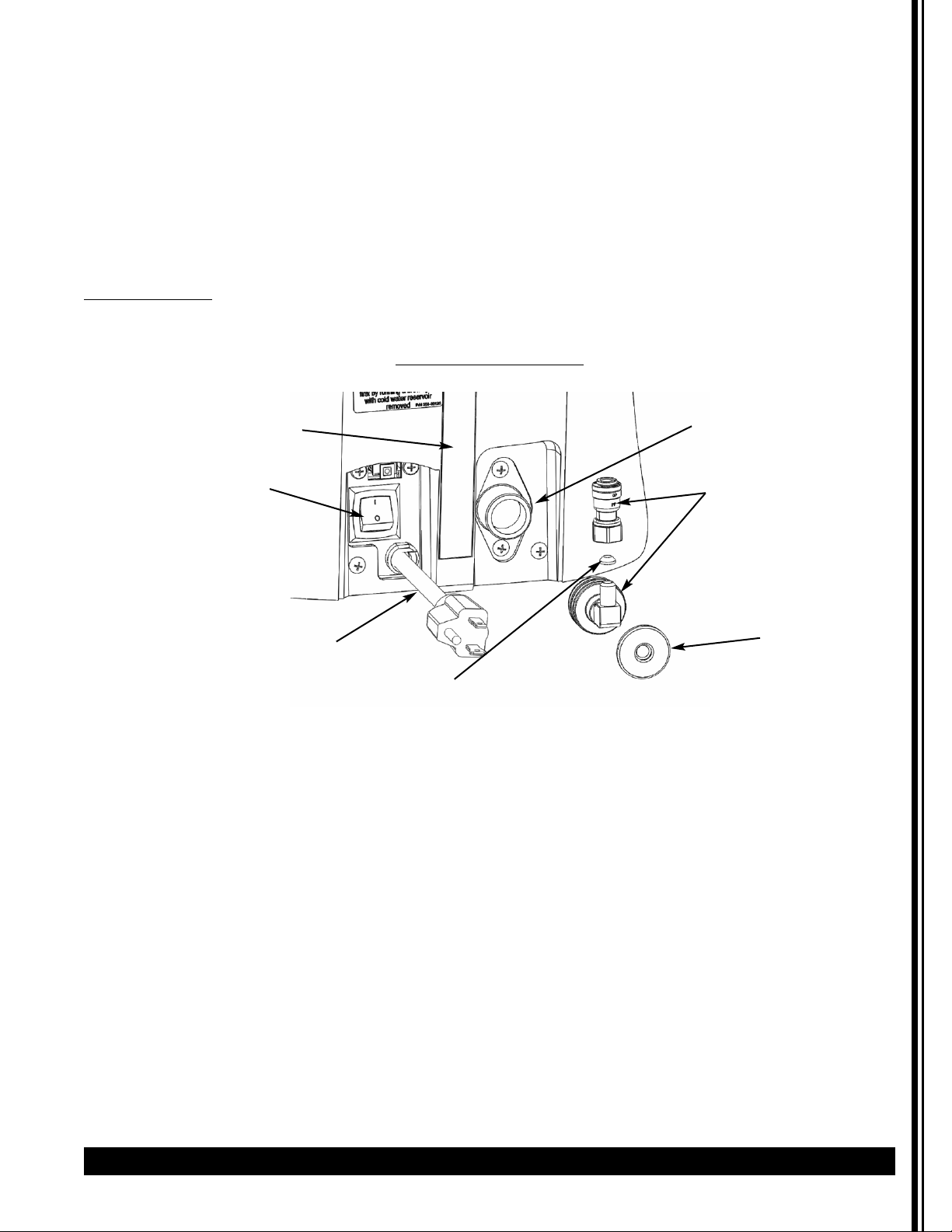

Water pipe connections and fixtures directly connected

to a potable water supply shall be sized, installed, and

maintained in accordance with federal, state, and local

codes. This product requires an approved back flow

prevention device, such as a double check valve, to be

installed between the machine and the water supply.

To prevent foreign material from entering the brewer,

keep brew chamber and reservoir lid closed.

To ensure proper operation of the electronic controls,

do not use reverse osmosis, distilled, or de-ionized

water.

The RC400 brewer hot water temperature is factory set

at 195°F (90.6°C). If your brewer is operated above 4000

feet in elevation, set point adjustment may become

necessary. If the brewer reservoir fogs or experiences

hot water dripping into the reservoir, this indicates the

set point must be lowered. In addition, if the set point

is too high, you could experience less than expected

brew volumes.

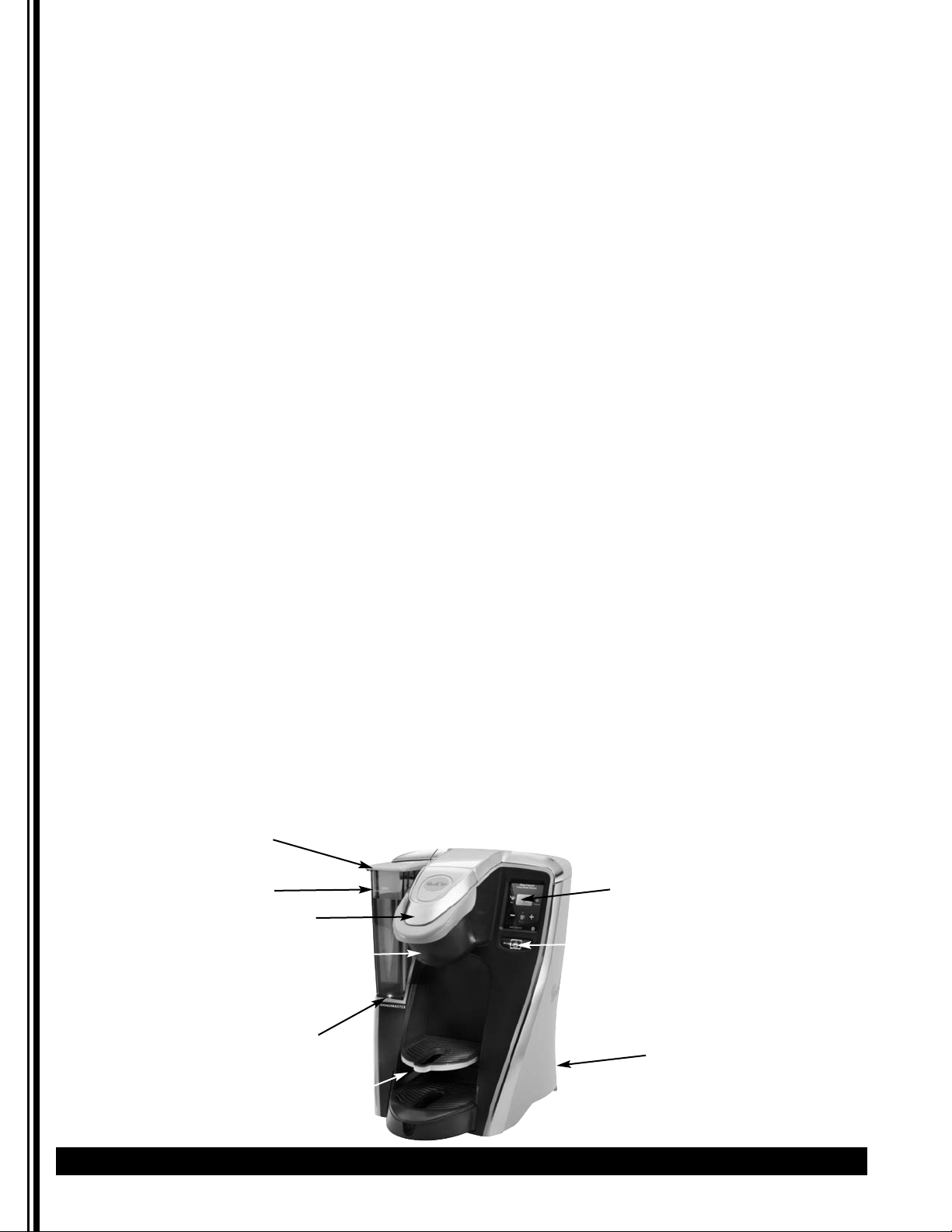

RC400 Features

Reservoir

Reservoir Lid

Brew Chamber Lid

Bezel

Reservoir LED

Pull Down Tray

Screen

Brew Button

Power Switch

(back side of brewer)