Page 12 of 36 General Machine Products (KT), LLC

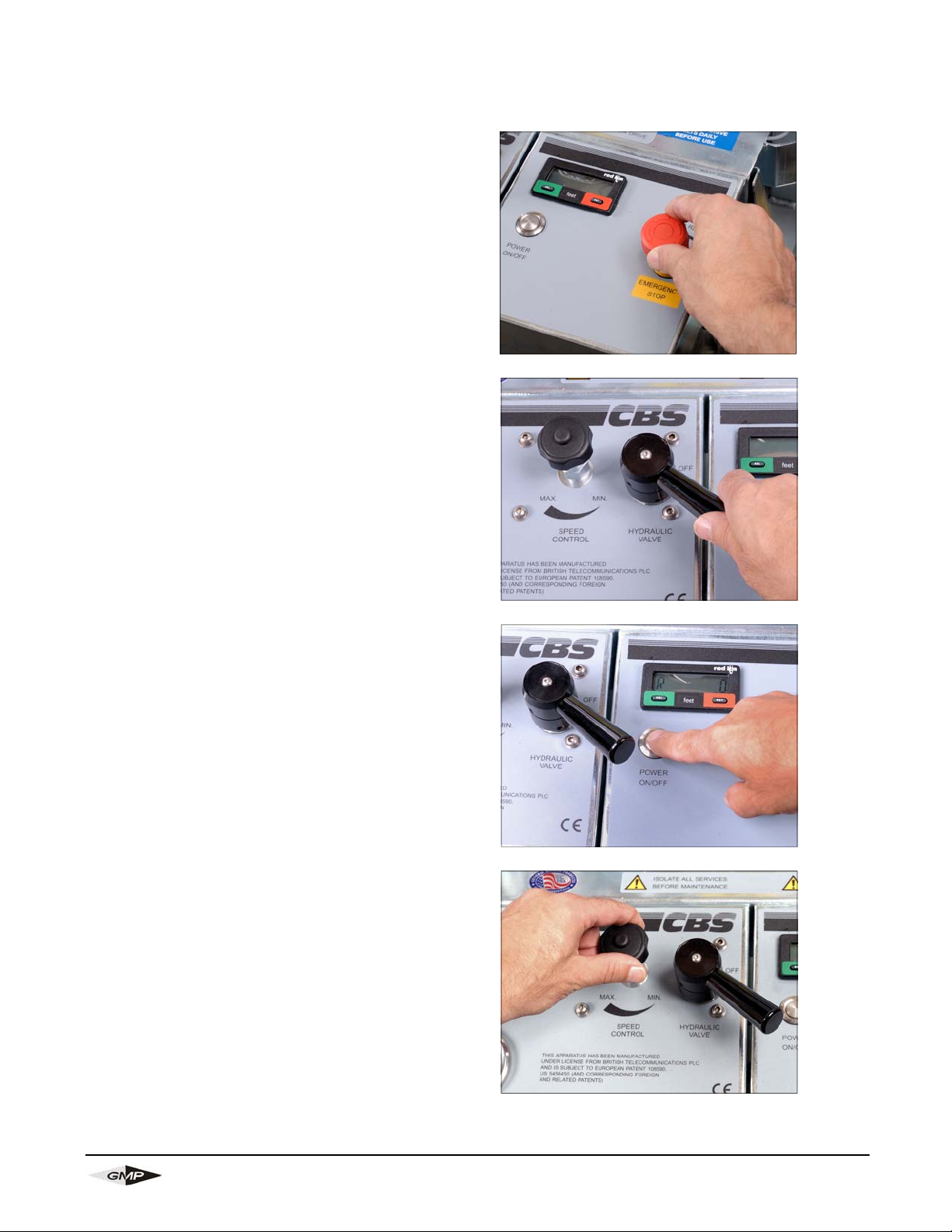

5. OPERATING PROCEDURE

It is imperative that all persons using, operation or maintaining this cable blowing ma-

chine:

Have received comprehensive training in the use of this machine.

Are competent and authorized to use it and have read and understand this manual.

General Machine Products (KT), LLC cannot be held responsible for misuse of this

equipment.

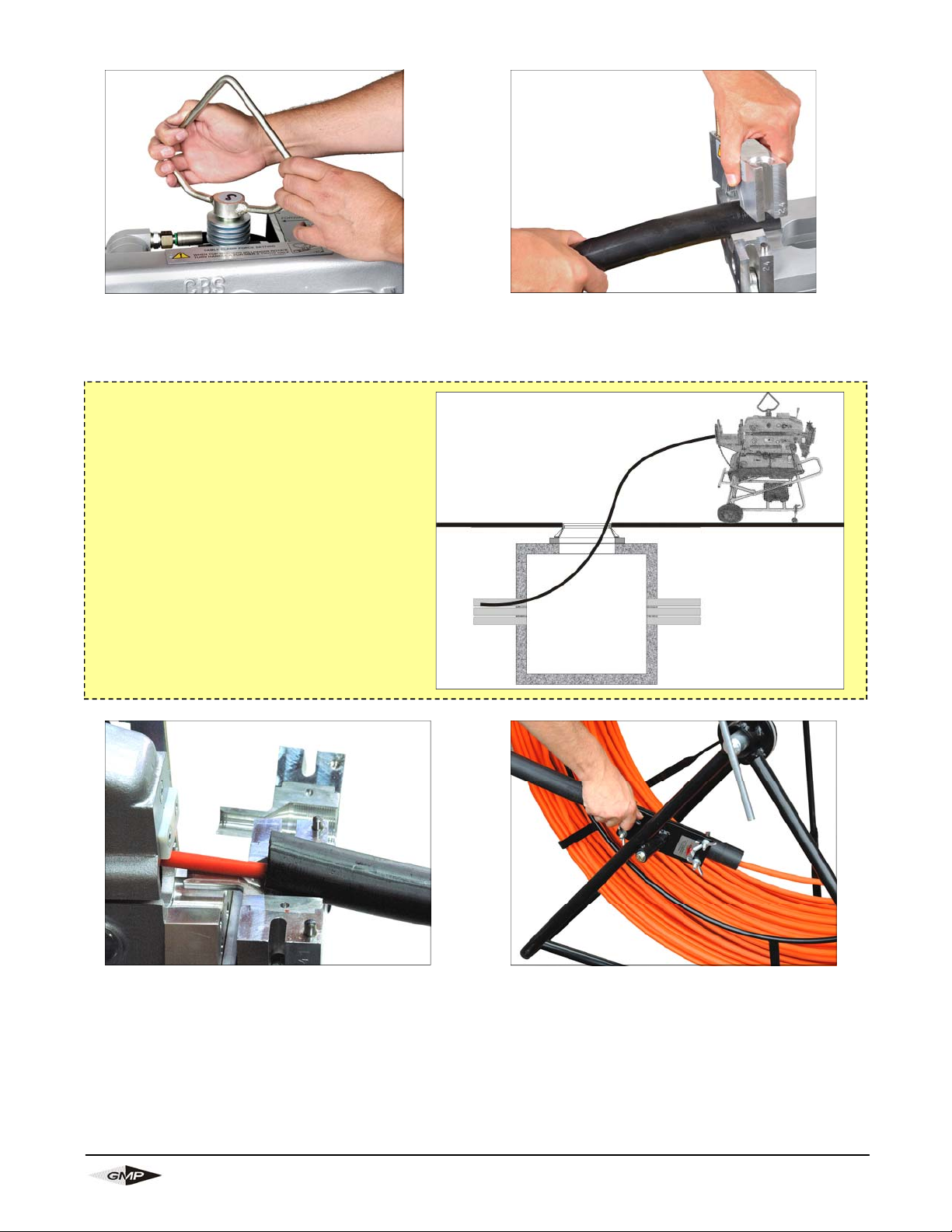

1. Position the Rod Pushing Machine in a suitable position in line with

the proposed sub-duct.

2. Adjust the mounting frame to the desired height and angle by means of the front frame sup-

ports. Withdraw the front ‘R’ clip and retaining pin while supporting the weight of the rod

pushing unit. Raise or lower the pushing unit and locate onto the support bar for the desired

position. Refit the retaining pin and ‘R’ clip. Alternatively the pushing unit may be detached

from the trolley frame by withdrawing both ‘R’ clips and retaining pins, while supporting the

weight of the pushing unit.

3. Stabilize the frame on uneven ground by adjusting the height on the pivoting feet at the rear

of the unit and locking in position.

NOTE: CARE SHOULD BE TAKEN WHEN WHEELING THE TROLLEY AROUND NOT TO

CATCH THE ADJUSTABLE FEET PADS ON CURBS OR BOULDERS, THIS MAY DAM-

AGE THE PIVOTING FOOT.

4. Position Duct Rod approximately 5’ behind the Duct Rod Pusher at about a 35° angle.

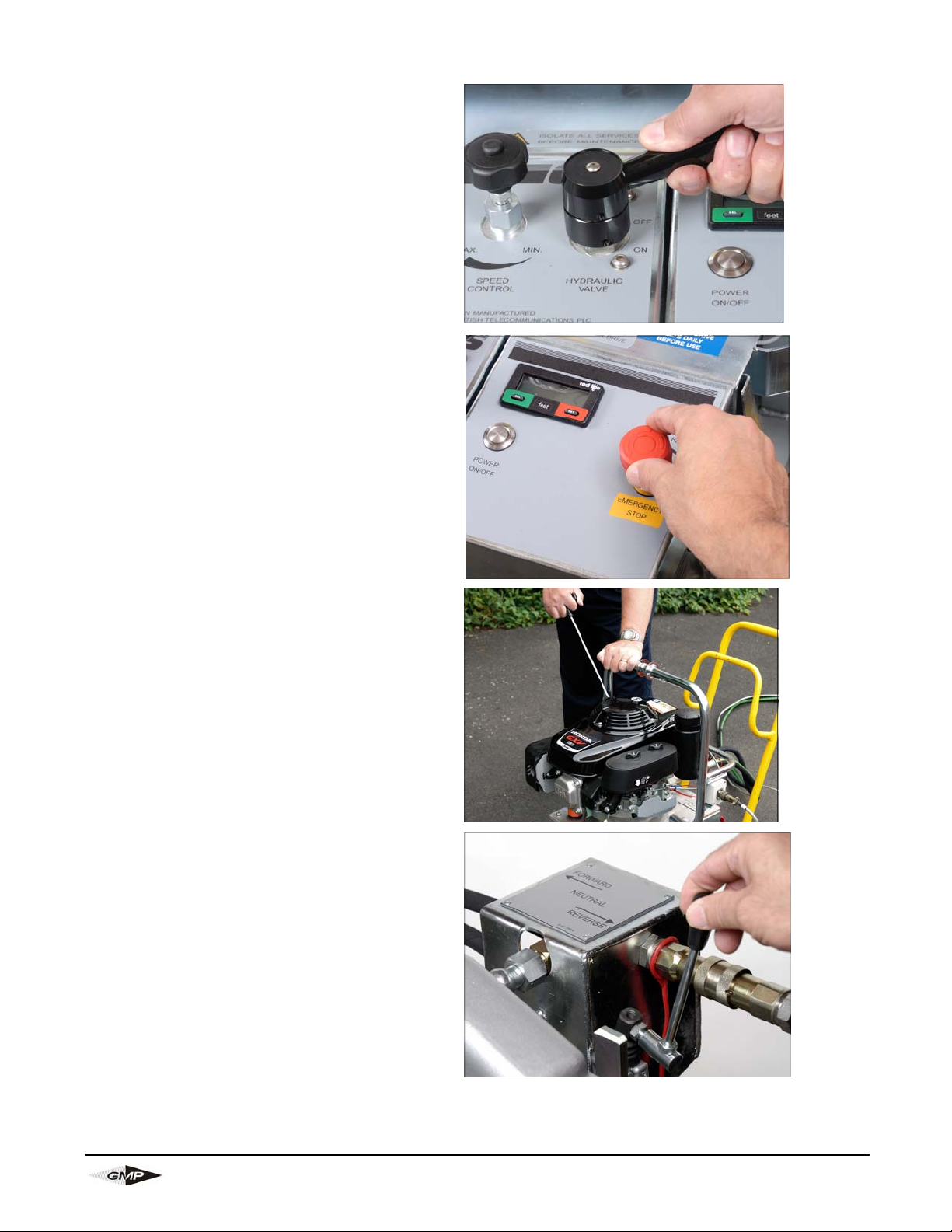

5. Insure the battery is fully charged before commencement of installation.

6. Open tractor drive.

CLEAN ANY DEBRIS, SLUDGE, DIRT, WATER, LUBRICANT,

ETC, FROM FRAME HOUSINGS AND ROD INTAKE GUIDE

BRACKET ASSEMBLY EACH TIME BEFORE USE.

LUBRICATE BOTH CHAINS BEFORE USE.

CLEAN BOTH TRACTOR DRIVE BELTS BE-

FORE USE.

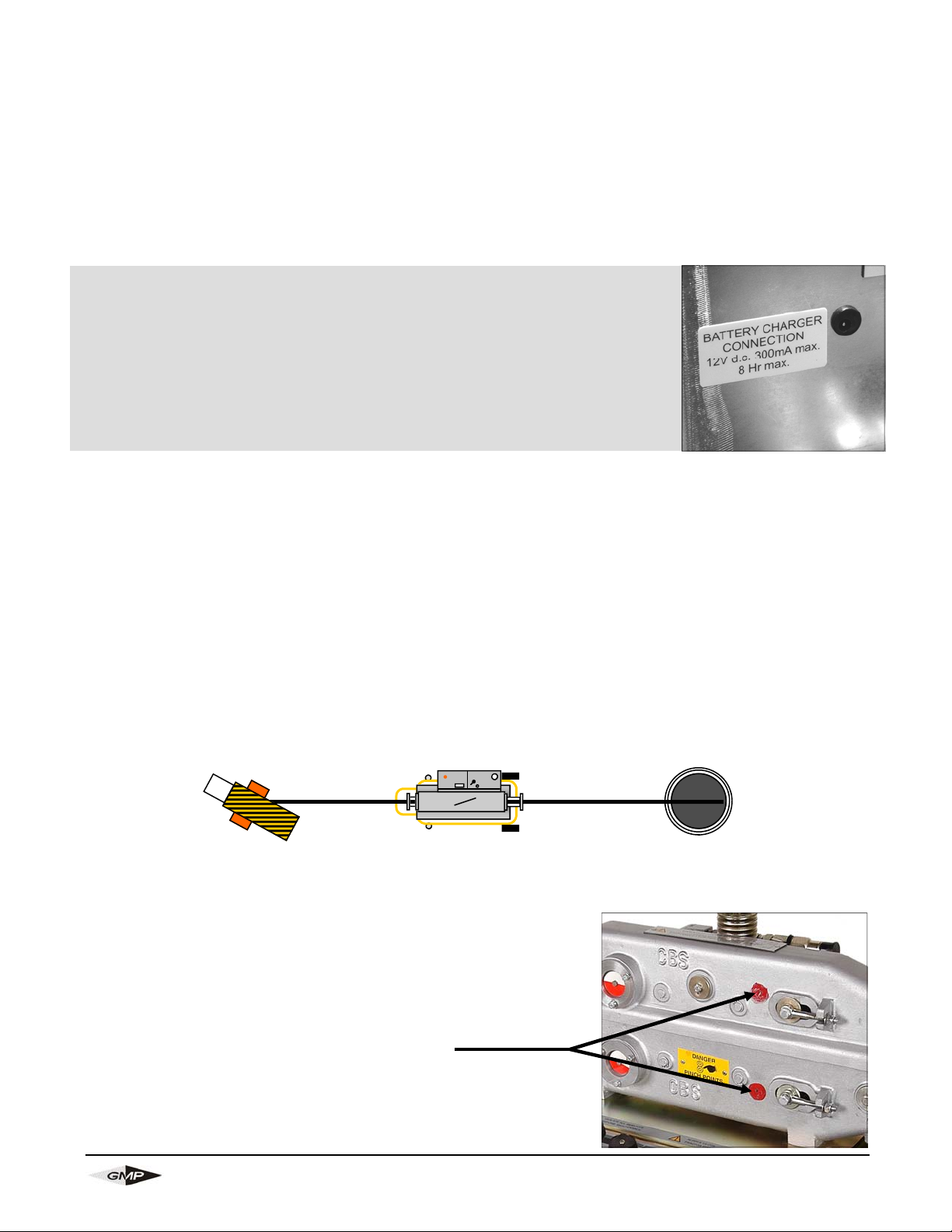

Charging the 12 volt battery before use:

Plug in the supplied battery charger in the charging jack found on the

right of the control panel. Initially charge the battery for 8 hours before

use (to approximately 13 volts). Continuous charging of the battery with

your charger will reduce the life of the battery. Remove the charger

when charging is complete. When voltage dips to 12 volts, recharge the

battery. Optimize battery life by turning off the display when not in use.

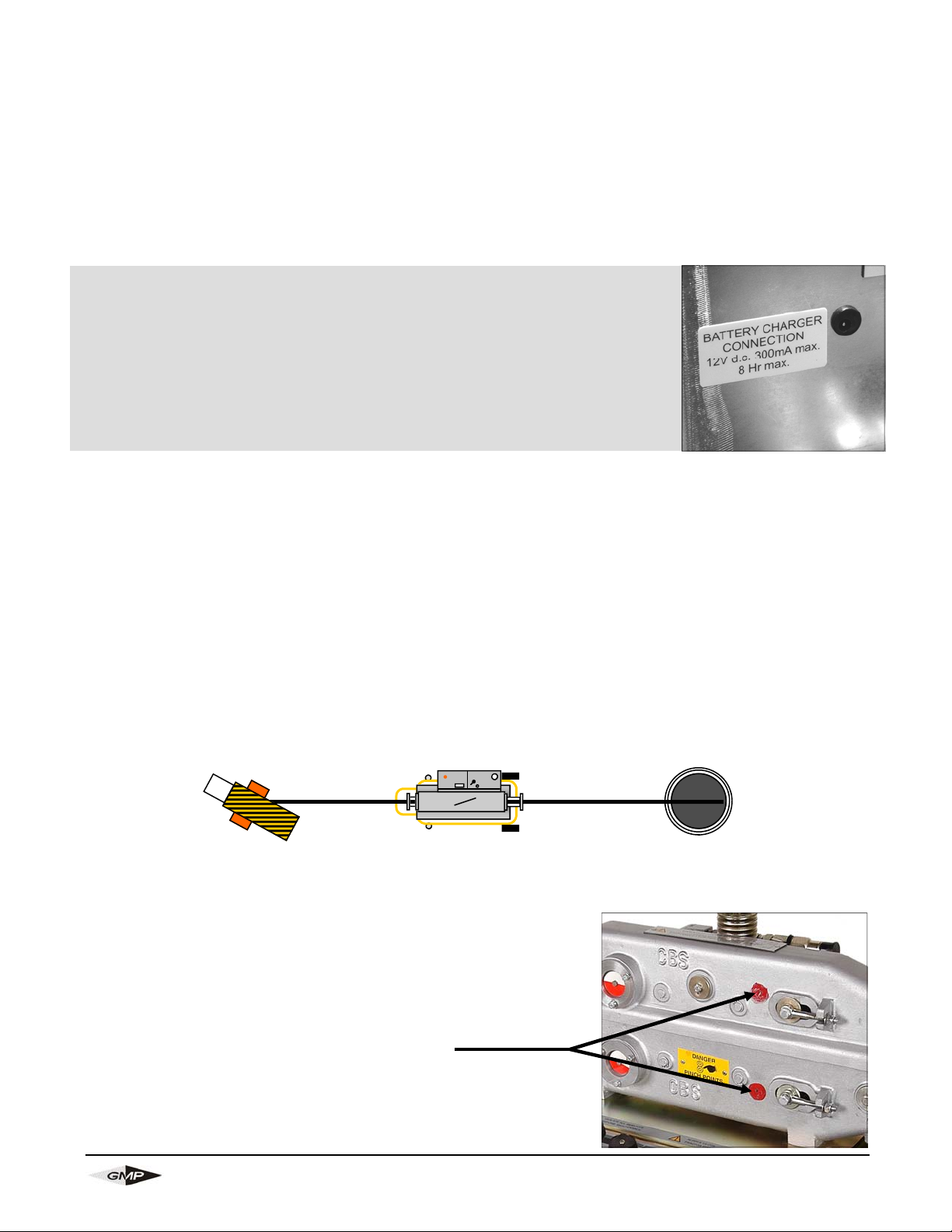

Lubrication Points

Duct Rod

Duct Rod Pusher

5ft 1 1/4” Duct 1 1/4” Duct