GMP AirStream 89299 Installation guide

Page 1

Operation and Maintenance

Model 89299

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form whatso-

ever without the written permission of General Machine Products Co., Inc.

General Machine Products Co., Inc. • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

CABLE BLOWING MACHINE

Manual P/N 33709 Rev 6

040616 AKK

PNEUMATIC

Page 2

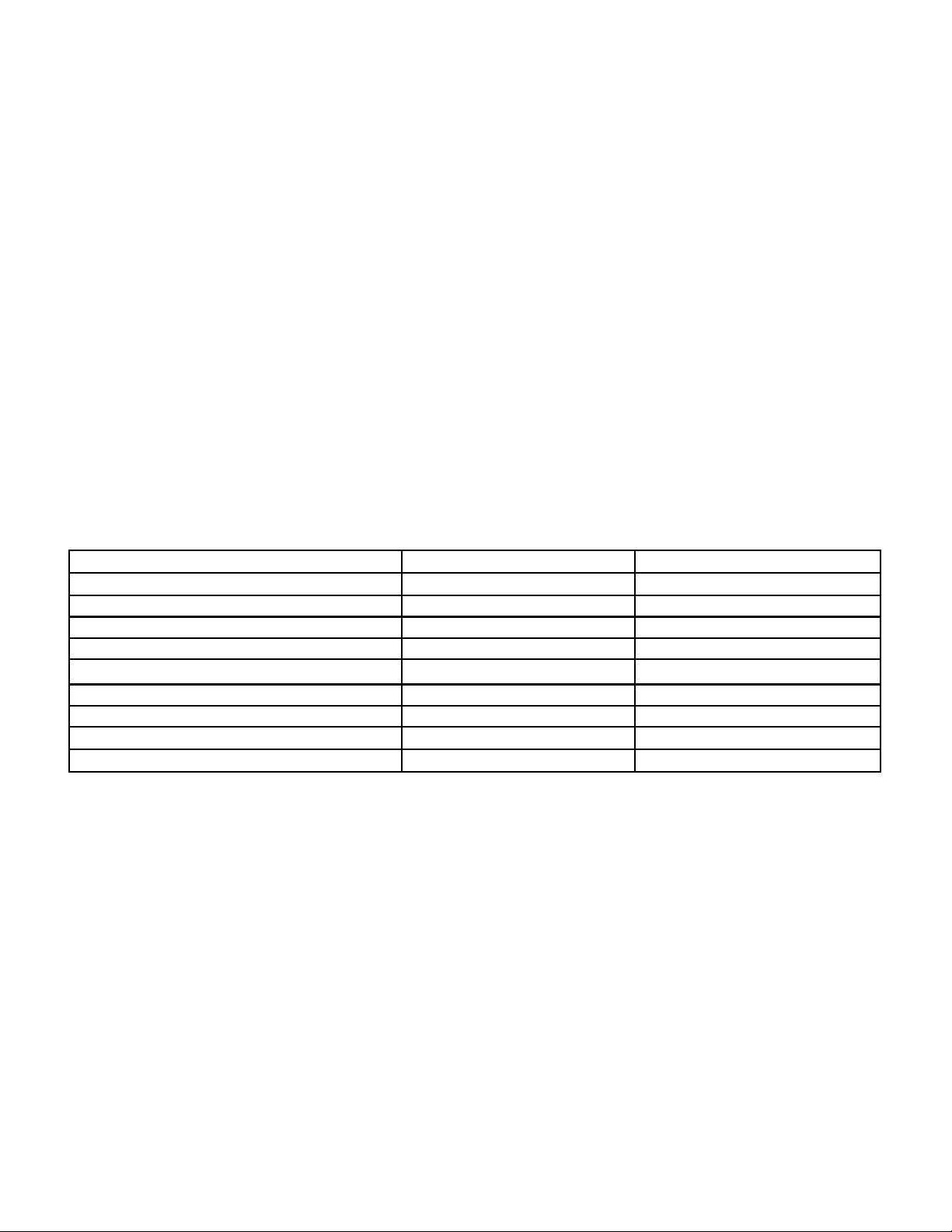

REVISION HISTORY:

Rev.no Date Details Author

01 Jul -27-10 Original issue A. Sibun

02 AUG-26-14 Reformat for US A. Konschak

03 April 8 15 Updated air supply quality A. Konschak

04 Jan 13 2016

Update Oiler adjustment and Oiler fill

Removed service details

Added 8.5mm

A Konschak

05 March 22

2016 Updated various photos A Konschak

06 April 5 2016 Added oil drip notification A Konschak

Page 3

CONTENTS

1. Safety Instructions

2. Critical Points that dramatically affect the operation of the machine

3. General Description

4. Specification

5. Operating procedures

6. Maintenance

7. Procedure for changing inserts in the microduct clamp

8. Procedure for changing inserts in the air box

9. Procedure for changing inserts in the infeed and exit guides

10. Procedure for replacing the air box housing seal

11. Procedure for changing the air box infeed guide

12. Procedure for changing the cable drive belts

13. Procedure for tensioning the drive belts

14. Procedure for checking and replacing the air motor drive belt

15. Tensioning of the air motor drive belt

16. Procedure for checking/refilling the oil level of the air lubricator

17. Monthly Service – check list

18. Service History Record

19. Microduct integrity and Lubrication

20. Recommended Spares List

21. Troubleshooting

APPENDICES

Appendix 1 Cable and microduct insert selection chart

Appendix 2 Recommended torque control potentiometer settings

Appendix 3 Counter/Rate meter Programming Instructions

Page 4

1.0 SAFETY INSTRUCTIONS

THIS EQUIPMENT SHOULD BE USED ONLY BY PERSONNEL WHO HAVE BEEN GIVEN THE

APPROPRIATE TRAINING, AND WHO ARE COMPETENT TO USE IT.

THESE INSTRUCTIONS ARE TO BE MADE AVAILABLE TO OPERATORS OF THIS EQUIPMENT

AT ALL TIMES, FAILURE TO OBSERVE THESE SAFETY INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY AND/OR PROPERTY DAMAGE.

WORK AREA AND GENERAL SAFETY

1. Read and understand the operation and maintenance manual supplied with this equipment. Keep it in a

convenient place for future reference.

2. Keep children and untrained personnel away from this equipment while in operation.

3. Keep all guards and safety devices in place. Do not operate this equipment with guards removed or dam-

aged.

4. Keep hands, feet and loose clothing away from moving parts, especially at cable entry points.

5. Always stop the machine and isolate compressed air and electrical services to carry out lubrication and ser-

vicing.

6. Check machine before starting for worn or damaged parts. Check for signs of loose nuts and bolts etc.

7. If machine is left unattended, ensure that unauthorized use is prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public places, observe all statutory require-

ments for working environments.

10. Beware of pinch points involved with rotating components,

11. Beware of hot surfaces, machine uses compressed air.

12. When operating machine always wear appropriate safety clothing, ear defenders, eye protection, hard hat,

safety shoes and leather gloves, machine operates with compressed air at up to 15 Bar.

13. Prior to installation ensure the microduct route is connected properly.

14. Beware of exposed electrical contacts. Do not touch, or allow metal objects to come into contact.

15. Machine may cause additional fire hazard if involved in an existing fire due to compressed air.

16. No personnel are to be in manholes or ducts when the Cable Blowing Machine is being operated.

17. The machine must be operated on firm ground.

18. Stay clear of cables or lines under tension.

19. Stay clear of pressurized air line and microduct.

20. Only use the machine for its intended purpose, do not use the roller drive without the air chamber to push

or to retrieve cable, blow air in the far end to help cable recovery.

21. Do not place cable drum too close to the Cable Blowing Machine.

22. The compressed air supply must not be allowed to enter the air chamber or microduct before the rollers

have been closed on to the cable. Do not turn the air on until a reasonable length of cable 150 ft. (50m) has

been installed into the microduct.

23. Ensure the cable drum rotates freely on its stand, the cable should leave from the top of the drum.

24. The cable should enter the machine in a clean and dry condition. In damp, dusty atmospheres, the cable

should be cleaned continuously as it enters the machine.

FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY, AS THE CABLE COULD

BE EJECTED FROM THE CABLE BLOWING MACHINE WITH HIGH FORCE AND

VELOCITY.

Page 5

GENERAL PNEUMATIC SAFETY INSTRUCTIONS

The GMP Fiber Optic Cable Blowing Machine is a pneumatic device, using pressurized air to project cable

at high velocities. Please observe the following precautions when operating the Cable Blowing Machine:

Compressed air can cause flying debris. This could cause personal injury. Always wear personal protec-

tive equipment.

Ensure no personnel are in the manhole at the far end of the cable run. Severe personal injury may re-

sult.

Never open the air chamber when pressurized.

Ensure the ball valve and flow control valve are fully closed before connecting the air supply to the motor

system. Unwanted operation and personal injury may otherwise result.

Only authorized, fully trained personnel should operate the air compressor.

GENERAL ELECTRICAL SAFETY INSTRUCTIONS

The machine has electronic and electrical power and control circuits. Electric shock hazards exist that could

result in severe personal injury. Observe the following precautions to avoid electrical hazards:

Do not operate in water. Do not expose the machine to rain.

Do not remove cover of electronic control panel or power supply unit. There are no user serviceable parts

inside. Refer servicing to qualified service personnel.

Page 6

2.0 CRITICAL POINTS THAT DRAMATICALLY AFFECT THE

OPERATION OF THE CABLE BLOWING MACHINE

PRESSURE ON THE CABLE (POSITION OF THE CLOSE ARM ASSEMBLY) SHOULD BE SET AS PER

THE INSTRUCTIONS.

BELTS TO BE CLOSED AT ALL TIMES WHEN CABLE IS INSTALLED INTO MACHINE.

CORD SEALS IN AIR CHAMBER IN GOOD CONDITION AND CORRECTLY FITTED TO PROVIDE

GOOD SEALING.

CORRECT CABLE SEAL FITTED.

MICRODUCT FULLY CONNECTED AND PRESSURE-TESTED.

MICRODUCT AND CONNECTING FITTINGS ARE SUITABLE FOR OPERATING AT 15 BAR AIR

PRESSURE.

MICRODUCT CLAMP SECURELY TIGHTENED.

COMPRESSOR CAPACITY >1.5m3/min @ 15 BAR CONTAINING NO MORE THAN 7.732 G/M^3 RE-

SIDUAL WATER CONTENT WITH A PRESSURE DEW POINT OF +3 DEG C AS PER DIN ISO 8573-1

CLASS 4.

CABLE DRUM MUST BE LOCATED DIRECTLY BEHIND AND IN LINE WITH THE BLOWING MA-

CHINE.

AIR CHAMBER, DRIVE BELTS AND PULLEYS, CABLE GUIDES, MUST BE CLEAN AND FREE FROM

DEBRIS, SLUDGE, DIRT, WATER AND LUBRICANT.

THE CABLE MUST BE HAND GUIDED INTO THE BLOWING MACHINE THROUGH A DRY CLEAN

CLOTH BY THE OPERATOR WEARING WORK GLOVES.

ENSURE THE COMPRESSED AIR SUPPLY IS NOT APPLIED TO THE CABLE UNTIL APPROXIMATE-

LY 50 METERS OF CABLE HAVE BEEN INSTALLED OR THE MOTOR BEGINS TO LABOR.

Page 7

DISCLAIMER

General Machine Products Co., Inc. takes care in the design of its products to insure

that the cable is protected during installation. Due to the variety and different methods

of cable manufacture the responsibility of checking the cable compatibility with the

equipment lies with the operator. Therefore, General Machine Products cannot accept

liability for any damage to the cable.

Page 8

3.0 GENERAL DESCRIPTION

The GMP Pneumatic AirStream machine is designed to install small diameter cable into underground

microduct.

The machine uses an air motor to drive a pair of compliant belts (both belts are driven).

The belts are covered with a compliant coating to prevent damage to the cable. A range of different coatings

and profiles are available depending on the surface texture of the cable being installed. The belts offer a

large surface area in contact with the cable ensuring high grip with reduced compressive loading.

During installation, the torque applied to the cable by the rollers can be adjusted to prevent the cable buckling

and to prevent damage to the cable. A full range of accessories is available to allow the machine to handle a

wide range of cables and microduct. This machine has been designed to be extra robust, reliable and simple

to operate by having only one power source. This means there is no need to have a generator on site, only a

compressor is required.

The machine may be placed on the ground or on a support to bring the cable to a suitable height. A separate

reinforced transit housing is provided, this will protect the machine from damage during transit and can be

used as a support for the machine when being used to install cable.

4.0 SPECIFICATION

Cable size: 0.098" to 0.433" ø2.5 to ø11.0

Microduct size: (OD) 0.197" to 0.709" ø5 to ø18.0

Cable speed: 0-262 ft/min 0-80 m/min.

Maximum pushing force: 48.5 lb. 22 Kg.

Maximum air pressure: 210 psi. 15 bar.

Recommended Compressor1 >1.5 m3/min @ 15 bar

Weight approx. 31 lbs. 14 Kg

Weight inc case approx. 68 lbs. 31 Kg

Dimensions (ht x length x width) 9 1/2"x 18 1/8" x 12 3/4" 240 mm x 460 mm x 325 mm

Case Dimensions (ht x length x width) 16 1/2"x 16"x 201/2" 419 mm x 521 mm x 406 mm

1 The compressed air supply is to contain no more than 7.732 g/m^3 residual water content with a pressure

dew point of +3 deg C as per DIN ISO 8573-1 Class 4.

Page 9

Cable Drum AirStream Machine

Microduct Route

5.0 OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING THIS CABLE

BLOWING MACHINE:

HAVE RECEIVED COMPREHENSIVE TRAINING IN THE USE OF THIS MACHINE.

ARE COMPETENT TO USE IT,

AUTHORIZED TO USE IT AND HAVE READ AND UNDERSTOOD THIS MANUAL.

GENERAL MACHINE PRODUCTS CO., INC. CANNOT BE HELD RESPONSIBLE FOR

MISUSE OF THIS EQUIPMENT.

Set up for installing cable with the machine mounted above ground:

Position the machine in line with the route of the duct.

Position the cable drum behind the machine and in line with the machine. See sketch below (this shows a

plan view of the recommended set up).

Ensure the machine is secure (either on its own stand or a separate suitable stand).

Ensure the machine is fitted with the appropriate guides and collets to suit the cable being installed and mi-

croducts into which the cable is to be installed. (See Appendix 1 for details of interchangeable parts).

To set the machine up to install cable it will be necessary to:

Select the appropriate torque setting for the cable being installed, if in doubt start with the low torque set-

ting.

Fit the microduct into which the cable is to be installed into the air box and microduct clamp.

Fit the cable through the machine.

Connect the air supply to the machine.

Connect the electrical power input to the machine.

Turn on the counter system.

Page 10

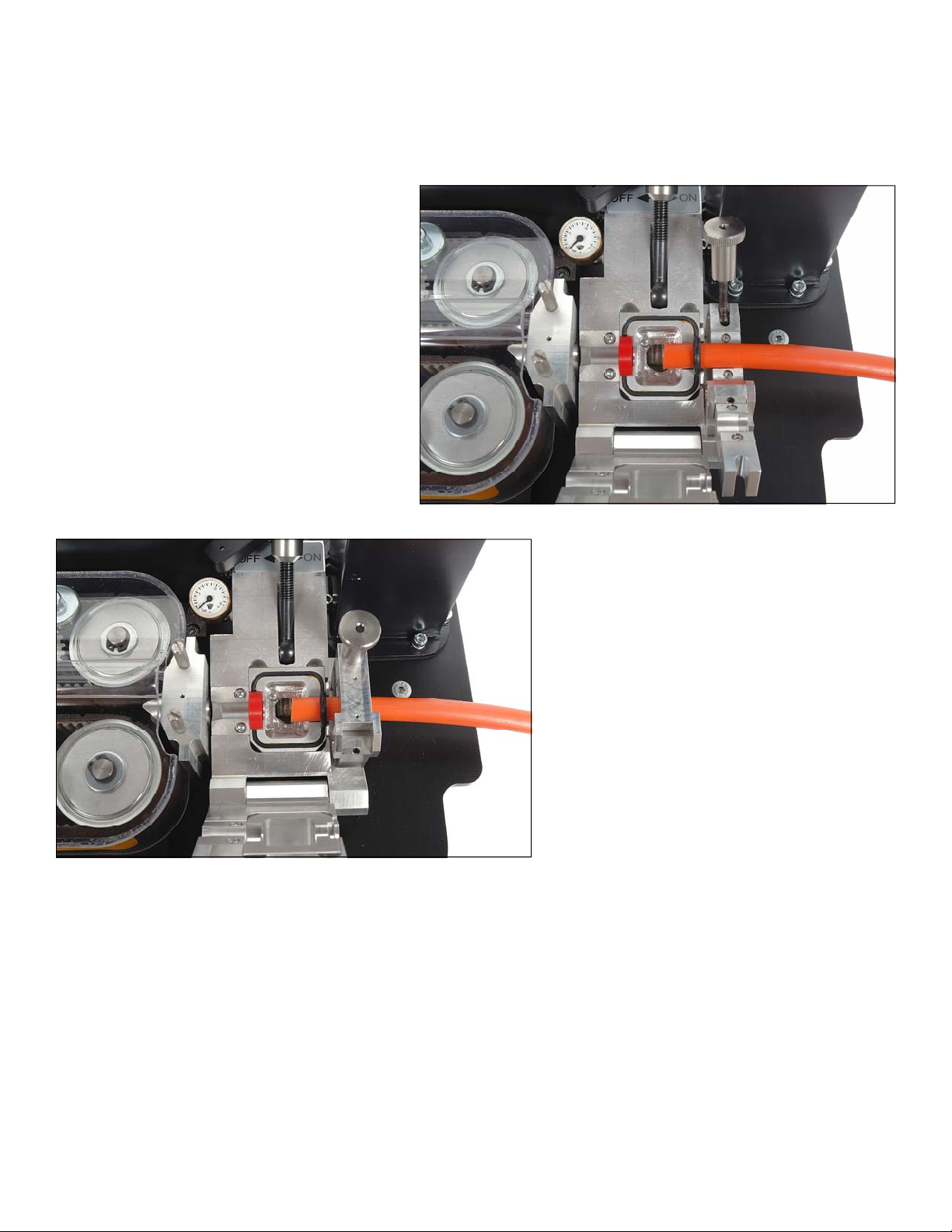

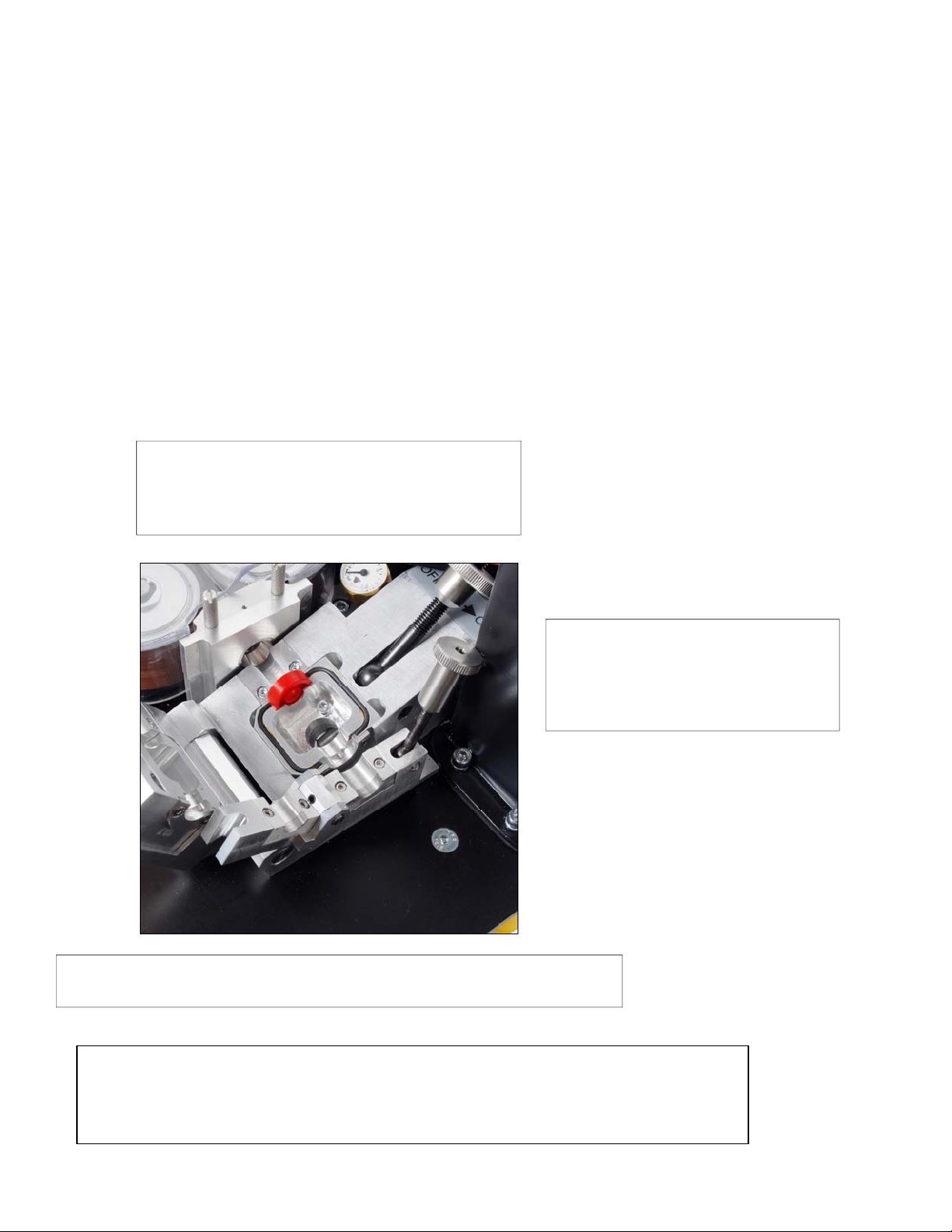

Fit the microduct into which the cable is to be installed into the air box and mi-

croduct clamp.

It is recommended that a length of microduct similar in size to the microduct into which the cable is to be in-

stalled be fitted in the microduct clamp. This length of microduct may then be connected to the installed mi-

croduct (the length of microduct under-

ground into which the cable is to be in-

stalled) using a suitable connector.

Slide a suitable size O ring over the end

of the microduct.

Fit the microduct into the end of the air

box housing so that it protrudes approx.

half way into the housing, position the O

ring so that it sits against the seal face,

as shown in the illustration opposite.

Once the microduct has been posi-

tioned, the microduct clamp may be

closed, the swing bolt swung down and

the thumb nut tightened, the microduct

is now secure.

Page 11

Fit the cable through the machine.

It is now possible to insert the cable in the machine, this can be carried out in 2 ways.

Method 1:

This method is only suitable if the machine has been previously set up with the correct infeed and exit guides

from the belts to suit the cable being installed, see section 9 for the procedure for changing the guides.

Fully close the flow control valve.

Set a pressure of roughly 2 bar.

Move the close assembly arm fully to the right.

Select the appropriate split cable seal (see appendix 1) and position it in the groove in the seal housing.

Open the ball valve and slowly turn the flow control valve knob counter clockwise until the belts are just

moving.

Take the cable to be installed and pass it through the infeed guide so that the end is between the belts.

Move the close arm to the left gently until the cable is gripped (there is no need to apply the full installation

pressure to the cable at this stage) – the cable should now feed slowly through the belts, cable seal, air

box and into the microduct.

Close the ball valve and the flow control valve to stop the machine.

Close and tighten the thumb nut securing the air box.

Prepare the machine to install the cable into the microduct.

Move the close assembly

to the far right to fully

open the drive

Loosen the thumb

nut and open the

seal housing

Page 12

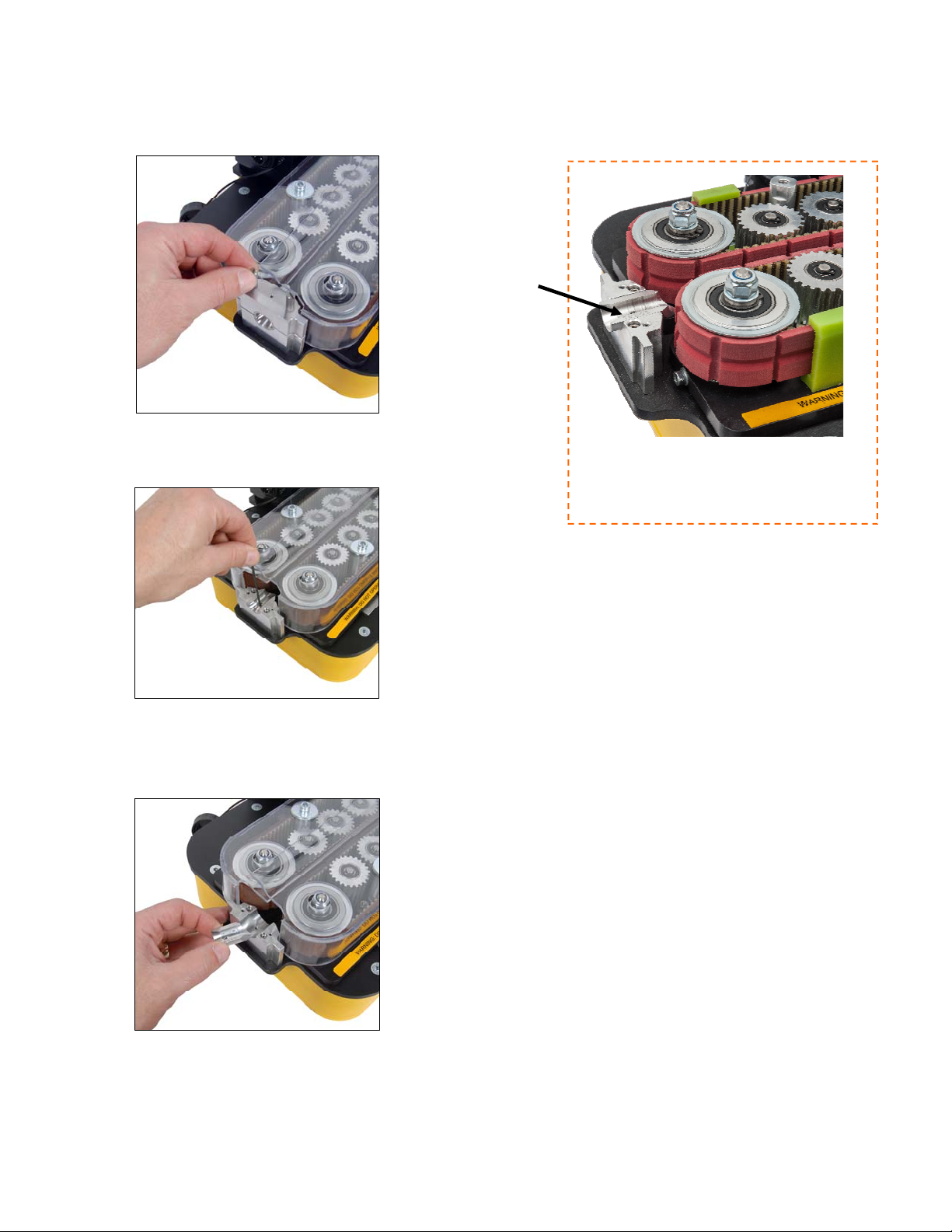

Method 2:

Move the close assembly arm fully to the right.

Remove the top halves of the belt infeed and exit guides using the knurled screws (screwdriver slots are

provided if necessary). Ensure the correct guides are fitted for the cable (see appendix 1)

Select the appropriate split cable seal (see appendix 1) and position it round the cable.

Take the cable and simultaneously place it into the microduct in the air box and thread it through the

gaps in the belts guards and between the belts. Ensure the cable seal seats in the appropriate groove in

the seal housing.

Replace the top halves of the belt infeed and exit guides.

Close the air box

Prepare the machine to install the cable in the microduct.

Setting the clamp force:

Close the drive roller assembly onto the cable as follows:

The photo shows the drive roller close thumb screw slightly

loosened. (The assembly is free to move).

This thumb screw is attached to the clamp arm lever.

The clamp arm lever controls the position of the roller as-

sembly.

As the clamp arm is moved around the arc the belts move

together and apart.

When the clamp arm is furthest to the right, the gap be-

tween the belts is at a maximum. And vice versa.

When preparing the machine to insert the cable, the clamp

arm is positioned at its furthest point to the right (rollers

open). Once the cable has been positioned in the machine the rollers must be closed on the cable in order

to drive the cable. (And to stop the cable being dragged back out of the machine by any tension in the ca-

ble).

The amount of pressure on the cable can be varied simply by loosening the thumb nut, moving the clamp

arm lever to the right or left; as required, and tightening the thumbscrew.

As more experience is gained using the machine, the amount of compression required will become clear.

Note:

An alternative method of setting the compression force is detailed in the note at the end of Appendix 2.

Close assembly

clamp lever arm

Page 13

Connect the air supply to the machine.

The air inlet to the machine is made via a jaymac coupling on either the

combined air input assembly and/or the jaymac connected to the back of

the air box. An on/off valve is fitted to the air box to provide control of the

air supply to the operator and a pressure gauge is fitted to indicate air

box pressure. Maximum safe working pressure is 15 Bar ( 210 psi).

Connect the battery to the counter circuit.

The two 9v batteries required to power the counter circuit have a connector each. These connectors are

handed and so cannot be connected incorrectly. Using a large coin simply twist through a quarter turn the 4

catches holding the battery box to the control housing to release them and gain access. Place the batteries in

the cradle, connect the power leads and then replace the battery box into its slot. Push the 4 catches until

they click into place and retain the battery box.

The on/off switch on the side of the counter assembly now controls power going to the counter. This should

be turned off when not in use to preserve battery life. The counter will remember the previous distance trav-

elled the next time it is turned on.

Connect the condensate drain

Push the provided length of 6mm microduct into the push-in fitting of the

condensate drain. Then place the other end of the microduct into a suitable

bottle so that any ejected condensate is collected and not released into the

environment.

The machine is now

ready to start the cable

installation.

Airlines are connected as shown

Page 14

Set up for installing cable with the machine mounted below ground:

The set up is similar to the set up for installing cable above ground, (described above) typically this type of

installation is demanded for “series blowing” i.e. when a length of cable is already installed, and the limit of

installation distance is reached. In such cases it is customary to couple a “series machine” sited down a man-

hole some distance from the point of main installation. This machine operates in conjunction with the ma-

chine sited at the main point of installation. The GMP Pneumatic Airstream machine is ideally suited to this

type of operation, it may be coupled with a second machine to increase the distance a single cable can be

installed without couplings. The only difference between this set up, and the set up for installing cable with

the machine above ground, is that there will be no drum stand carrying the cable drum. The cable will be exit-

ing from one side of the manhole and blown into the microduct at the other side of the manhole. The machine

should be aligned with both the incoming cable and the outgoing microduct path, both side to side and up and

down.

NOTE: THE MACHINE MUST NOT BE SUBMERGED IN WATER.

If the hole is full of water it must be pumped out before placing the machine on the bottom of the hole.

Page 15

Installing cable.

The machine is fitted with a range of controls to help the operator to install cable in the minimum time with the

least risk of causing damage to the cable or microduct.

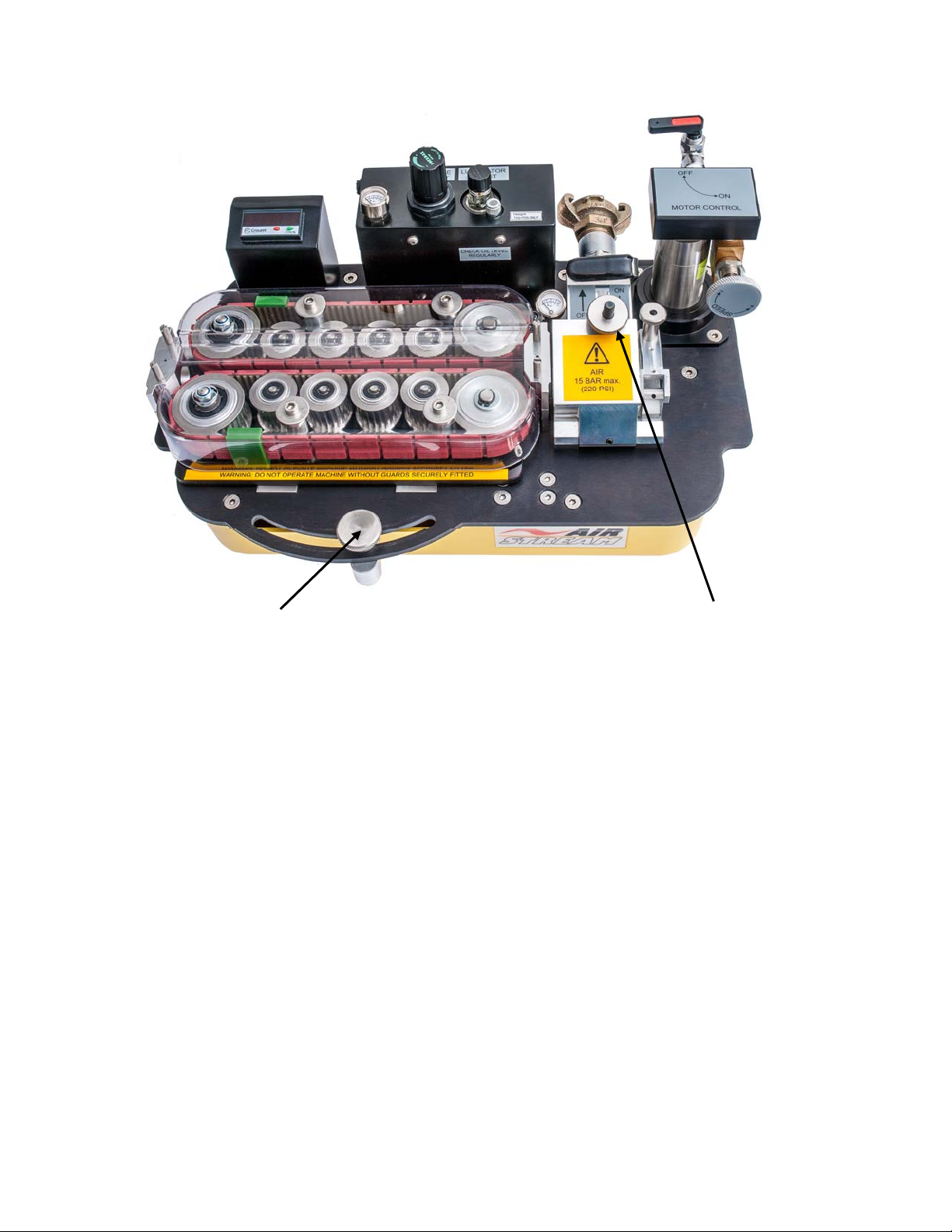

These controls are identified and their function is described below.

Torque control:

This is controlled via the pressure regulator in the control housing. A higher pressure setting corresponds to

more available torque. Follow the + / - markings on the control knob and note the setting on the pressure

gauge. We recommend settings between 2 to 8 bar dependant on cable size.

Speed control:

The needle flow control valve restricts the motors exhaust and therefore adjusts the speed of the machine.

Turn the knob clockwise to decrease flow (speed) and counter clockwise to increase flow.

On/Off Motor Air Valve:

This ball valve controls air flow to the motor. Since it is between the motor and the pressure regulator, it al-

lows the operator to set the correct pressure before he/she begins installing. The valve (along with the flow

control valve) should always be closed before the air line is connected to the machine to prevent unwanted

and potentially dangerous operation.

Speed Distance indicator:

This device will measure and display the distance traveled by the cable and also the speed at which the cable

is traveling. To toggle between speed (‘tacho’) and distance (‘count’) modes press the right-hand (green) but-

ton on the counter face twice. Pressing this button once displays the current mode (either ‘count’ or ‘tacho’).

To reset the distance to zero press the left hand (red) button.

Note: It is only possible to reset the distance to zero if you are in ‘count’ mode. Pressing the reset but-

ton while in ‘tacho’ mode will do nothing.

Should it be necessary to replace the speed distance-measuring device please contact GMP.

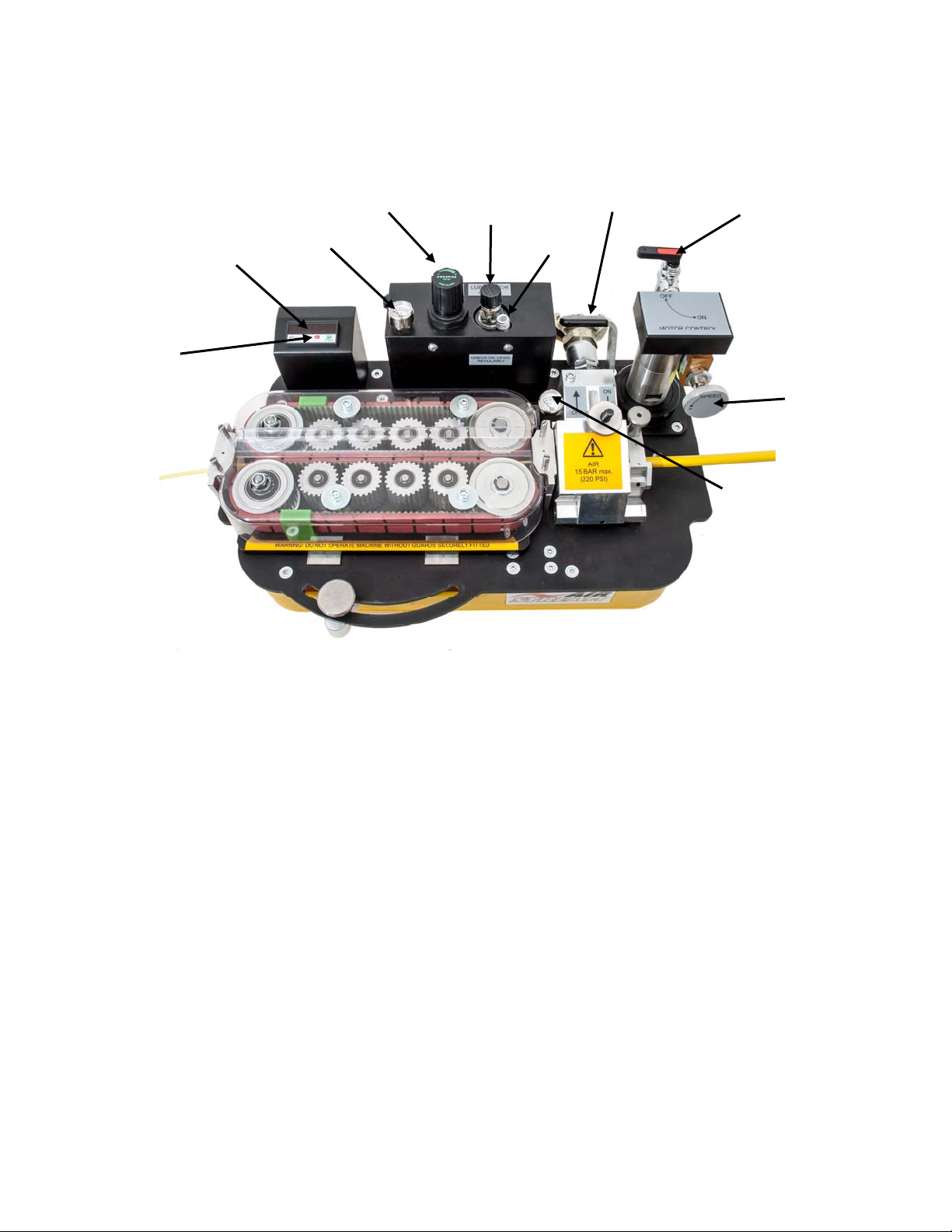

Speed/

Distance

Indicator

Reset

Torque

Control On/Off Motor

Air Valve

Speed

Control

Fiber

Air Valve

Air

Pressure

Motor Oiler

Adjustment

Oil Fill

Fiber Air

Pressure

Page 16

To install cable:

For the first time i.e. installing a cable type that has not been installed before and whose characteristics are

unknown.

Using the supplied airline adaptor, connect the air lines to the

machine and the compressor (checking the ball valves and

flow control valve on the motor are closed).

It is now necessary to set the torque to a position appropriate

to the stiffness of the cable and the characteristics of the cable

insulation. This is done via the control knob and pressure

gauge, if in doubt start at 2 bar. See Appendix 2 for recom-

mendations. If the cable type has been installed before, the

settings will be available; the torque control pressure may be

set at the previously determined position.

Open the motor ball valve.

Slowly open the flow control valve.

The rollers will now start to turn and the cable will feed through

the air box (increase speed setting to max. if required). When

the cable has travelled a reasonable distance, (say 100 me-

ters) turn on the air feed to the air box; this will help the machine to feed the cable.

The microduct route, through which the cable is to be fed, should be configured in such a way that the cable

can feed all the way along the microduct and out the other end. It will be necessary to be able to determine

when the cable has emerged at the other end of the microduct route. A typical way of achieving this aim is to

have a colleague positioned at the end of the microduct run; in contact with the main installer using a radio

transmitter/receiver of some description. In this way the main installer may be advised when the cable has

completed the run, he can then stop the machine.

If there is an unexpected obstruction in the microduct route the rollers will see this as an increase in torque

demand, assuming the torque control pressure has been set at an appropriate level, the rollers will stop turn-

ing before they push the cable so hard as to cause it to buckle. If (due to lack of previous knowledge of the

cable characteristics) the torque control pressure has been set at a figure which is too small to push the cable

the setting may be increased. Bear in mind that this will increase the risk of the cable being damaged by

buckling.

Grounding the Airstream Cable Blower.

Certain cable/duct combinations can generate large static build-

ups. If this is occurring, ground the Airstream via the ground

point on the air box via a suitable copper conductor to a ground

at the power source or earth.

Grounding Point

Airlines are connected as shown

Page 17

As a general rule, every time an interchangeable part is removed and replaced by a

part of a different size, shape etc. the part being removed should be thoroughly

cleaned before being returned to its box. Similarly the cavity from which it was re-

moved can also be cleaned prior to the assembly of the replacement part.

Air box parts: keep clean, build up of moisture

and dust will prevent the joint faces from mating,

prevent the housing seal from sealing etc. Use

any traditional workshop cleaning agent.

Microduct clamp inserts: keep

clean, build up of moisture and dust,

particularly in the grooves, will re-

duce the clamping effect. Use tradi-

tional workshop cleaning agent.

Cable infeed and exit guides: keep clean, build up of moisture and dust

may nip the cable. Use any traditional workshop cleaning agent.

6.0 Maintenance

The GMP AirStream Cable Blowing Machine has been designed to give reliable, trouble free service over

long periods. The machine requires no sophisticated maintenance procedures, simple common sense

checks and precautions are all that are needed.

The main source of breakdown and/or malfunction of a machine being used outdoors is contamination by the

elements, this contamination may be introduced into the machine in a number of different ways.

There may be mud, dust or other contaminants carried into the machine on the cable or microduct (there may

be surface coatings of lubricants or other release type agents on the outer surfaces of the cable and mi-

croduct, this could build up on the belts and make them slip).

The machine may be set down on a muddy surface, or be splashed by road going vehicles when it is being

used by the roadside.

It is convenient to consider each function of the machine in turn.

Page 18

The machine should be returned to the manufacturers after every 1000 hours use (or at intervals of 12

months) for a major service.

Clean Drive Belts

(Warm soapy water) Clean debris from between

the belt drive assemblies

Ensure free rotation of rollers

Preventing as much contaminant as possible from entering the drive belt assemblies will aid the performance

of the machine. If necessary remove the drive belts. (See section 12.0) and clean the assemblies. Ensure free

rotation of rollers and smooth action of the Cross Arm assembly

It is necessary to periodically inspect inside the base (See section 14.0 for base removal) to check for belt

wear, debris and pulley wear/damage. Inspect the flanges on the pulleys are securely retained, bearings ro-

tate freely and all set screws are secure.

Page 19

Loosen the thumb nut, rotate the

swing bolt to open the microduct

clamp housing

Loosen and remove the (2) m2.5 fix-

ing screws. (Do not lose these

screws, they will be needed for the

replacement insert).

Remove the insert

Loosen the thumb nut, rotate the swing bolt

to open the air box

Loosen and remove the m4 fixing screw.

(Do not lose this screw, it will be needed for

the replacement insert)

Remove the insert

Repeat the process for the insert in the other

box half

To fit the new inserts, reverse the disassem-

bly procedure.

7.0 Procedure for changing inserts in the microduct clamp

Repeat the process for the insert in the other housing half

To fit the new inserts, reverse the disassembly procedure.

8.0 Procedure for changing inserts in the air box

Page 20

Unscrew knurled screws secur-

ing the upper guide housing

Loosen and remove the M2.5

screw securing the guide into

the housing

Remove and replace the guide

If both long and short inserts are

used, the long inserts are mounted

in the housings at the machine inlet

Long Insert

9.0 Procedure for changing inserts in the belt infeed and exit

guides

Table of contents

Other GMP Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SUHNER MACHINING

SUHNER MACHINING AG 12-2 installation instructions

PCB Piezotronics

PCB Piezotronics RHM240M40 Installation and operating manual

Eaton

Eaton SL4-PIB Series Instruction leaflet

IKA

IKA RC 5 control operating instructions

Neslab

Neslab Steelhead 1 Instruction and operation manual

RCI

RCI L65 Series installation instructions